High-Performance Honeycomb Flow Straightener for Panels

The Critical Role of Honeycomb Flow Straighteners in Modern Industrial Systems

In diverse industrial applications ranging from aerospace testing to HVAC systems and advanced chemical processing, the precise control of fluid dynamics is paramount for optimizing performance, ensuring measurement accuracy, and enhancing operational efficiency. Turbulent flow, characterized by chaotic and unpredictable fluid motion, can lead to significant pressure drops, increased energy consumption, inaccurate sensor readings, and premature wear on downstream equipment. This is where the honeycomb flow straightener emerges as an indispensable component. Designed to transform turbulent fluid streams into uniform, laminar flows, these devices are critical for mitigating adverse flow effects and creating an ideal environment for precise operations. Manufactured from high-grade materials like Stainless Steel 304 and 316L, they offer unparalleled durability and corrosion resistance, essential for demanding industrial environments. The intricate cellular structure of a honeycomb panel acts as a series of miniature conduits, guiding the fluid and eliminating swirls and vortices, thereby ensuring a stable and predictable flow profile. This foundational technology underpins numerous advanced systems, contributing significantly to energy conservation and the reliability of complex industrial processes worldwide.

The increasing complexity and precision requirements of modern industrial processes have driven a growing demand for highly efficient flow conditioning solutions. Industries such as petrochemicals, power generation, aerospace, and environmental engineering continuously seek ways to optimize their systems, reduce operational costs, and comply with stringent regulatory standards. For instance, in power generation, achieving uniform air distribution within combustion chambers can directly impact fuel efficiency and emissions. Similarly, in wind tunnels, a perfectly laminar flow is crucial for accurate aerodynamic testing. The inherent design of the honeycomb flow straightener, with its high aspect ratio cells, provides an excellent solution for achieving this uniformity, minimizing pressure losses while effectively conditioning the flow. The use of specialized materials such as Stainless Steel 304 and 316L ensures that these components can withstand extreme temperatures, corrosive media, and high-pressure environments, offering an extended service life and reducing maintenance requirements. This robust construction makes them a preferred choice over conventional methods, delivering superior performance and long-term economic benefits for a wide array of critical applications.

Unpacking the Technology: Manufacturing Process of Stainless Steel Honeycomb Cores

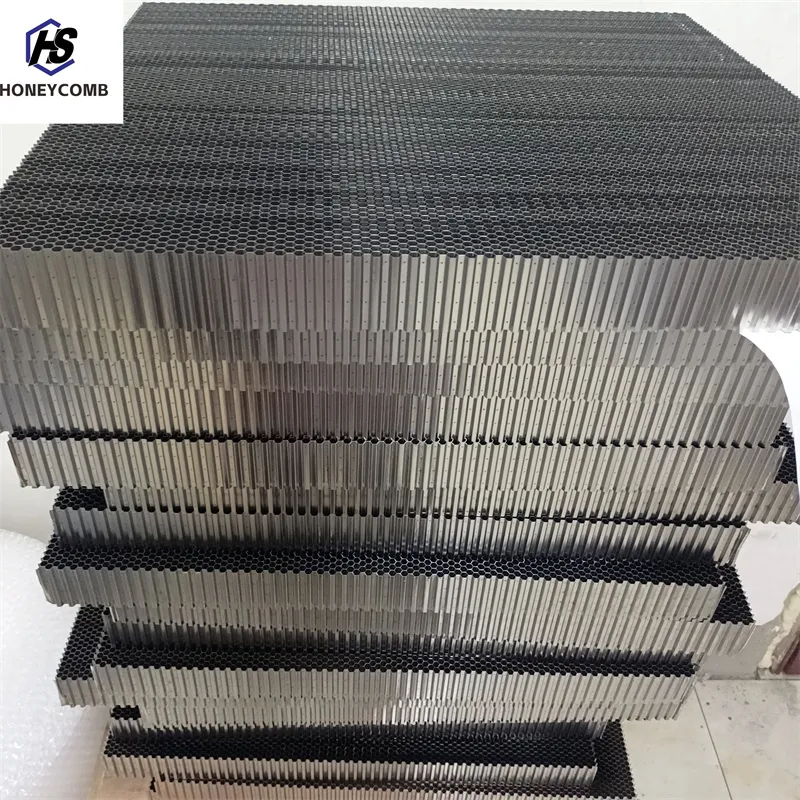

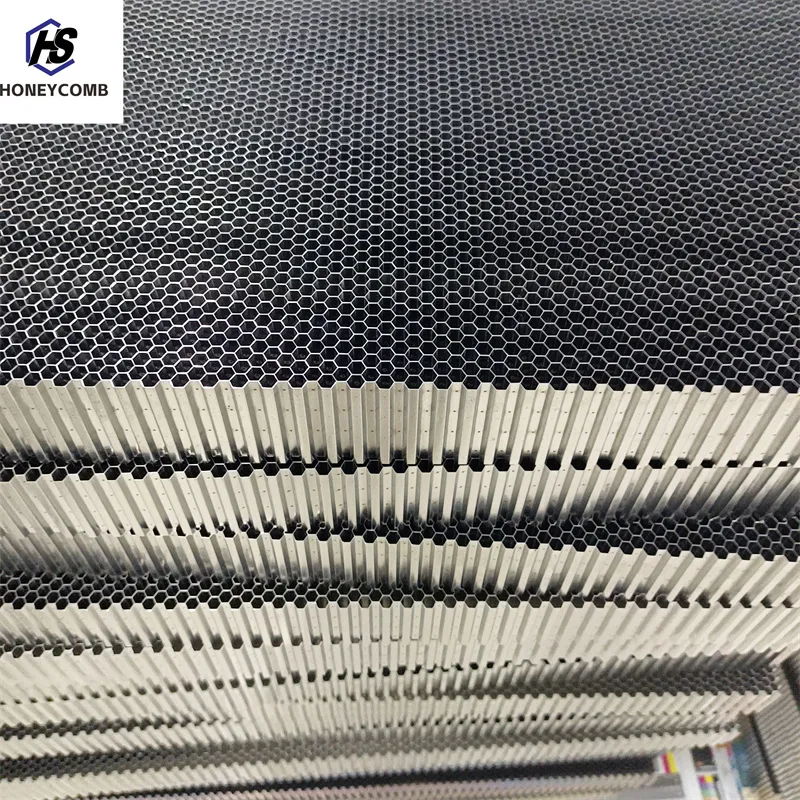

The manufacturing of a high-quality honeycomb flow straightener involves a sophisticated multi-stage process, ensuring both structural integrity and precise flow conditioning capabilities. It begins with the selection of premium-grade raw materials, primarily Stainless Steel 304 or 316L, chosen for their exceptional corrosion resistance, high-temperature stability, and mechanical strength. Stainless Steel 304 is ideal for general industrial applications, offering good formability and weldability, while 316L, with its added molybdenum content, provides superior resistance to pitting and crevice corrosion, making it suitable for marine or highly aggressive chemical environments. The manufacturing process typically involves precision corrugation, where flat stainless steel foils are meticulously shaped into sinusoidal waves. These corrugated sheets are then bonded together with flat sheets to form the characteristic hexagonal cell structure, often using advanced diffusion bonding or resistance welding techniques to ensure strong, seamless joints. This ensures the structural rigidity of the honeycomb panel, crucial for maintaining its shape under various operational pressures.

Figure 1: Illustration of a Stainless Steel Honeycomb Core structure.

Subsequent steps include precise cutting and shaping of the honeycomb blocks into the desired dimensions and configurations, often utilizing advanced CNC machining for unparalleled accuracy. This stage is critical for achieving tight tolerances essential for effective flow straightening. Post-processing may involve surface treatments to further enhance corrosion resistance or prepare the surface for integration into larger assemblies. Throughout the entire manufacturing chain, stringent quality control measures are implemented. Products are rigorously tested against international standards such as ISO (International Organization for Standardization) for quality management systems and ANSI (American National Standards Institute) for specific product performance criteria. These tests include dimensional accuracy checks, pressure drop measurements, flow uniformity assessments, and material integrity verification. The typical operational lifespan of a Stainless Steel honeycomb flow straightener can extend beyond 15-20 years under normal operating conditions, owing to its robust material properties and design. Applicable industries include petrochemicals for reactor inlet conditioning, metallurgy for gas distribution in furnaces, and water treatment systems for improved mixing and aeration, all benefiting from enhanced energy efficiency and corrosion resistance provided by these specialized components.

Technical Deep Dive: Key Parameters and Performance Metrics

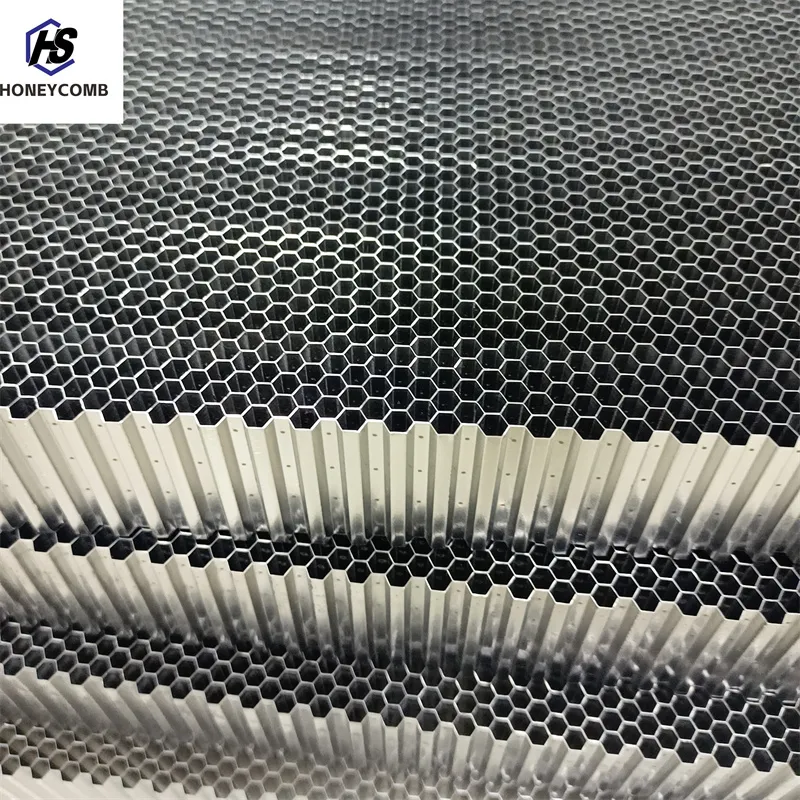

Understanding the technical parameters of a honeycomb flow straightener is crucial for selecting the optimal design for a specific application. Key parameters include cell size, which refers to the diameter or width of individual hexagonal cells; wall thickness, the thickness of the stainless steel foil forming the cell walls; and aspect ratio, defined as the ratio of cell length to cell size. The open area percentage, indicating the proportion of the total cross-sectional area through which fluid can pass, significantly impacts pressure drop and flow rate. Material grade, typically Stainless Steel 304 or 316L, dictates corrosion resistance, temperature limits, and mechanical strength. These parameters collectively determine the flow straightening efficiency, the resulting pressure drop across the device, and its structural integrity. For instance, a smaller cell size and higher aspect ratio generally lead to more effective flow straightening and reduced turbulence intensity, but may also result in a slightly higher pressure drop. Conversely, larger cells and lower aspect ratios facilitate higher flow rates with minimal pressure loss, suitable for applications where perfect laminar flow is not strictly required.

Figure 2: A closer look at the precise cellular structure.

Performance metrics are quantifiable indicators of a honeycomb flow straightener's effectiveness. The most critical metrics include the percentage reduction in turbulence intensity, often measured using hot-wire anemometry or Particle Image Velocimetry (PIV), and the uniformity of the velocity profile downstream. A well-designed straightener can reduce turbulence intensity by over 90%, transforming highly chaotic flow into a near-laminar stream. Pressure drop, a measure of the energy lost as fluid passes through the straightener, is another vital consideration; efficient designs minimize this loss to conserve energy. Froude numbers and Reynolds numbers are critical dimensionless quantities used in fluid dynamics to characterize flow regimes and predict performance. High Reynolds numbers indicate turbulent flow, while low Reynolds numbers suggest laminar flow. A straightener's design aims to effectively manage these numbers to achieve the desired flow characteristics. The table below provides typical specifications and performance data for Stainless Steel honeycomb flow straightener units, illustrating the range of options available and their impact on operational parameters. These data points are crucial for engineers and designers to make informed decisions, balancing flow conditioning requirements with energy efficiency and system constraints for optimal system integration.

Strategic Applications and Industry Benefits: Where Honeycomb Flow Straighteners Excel

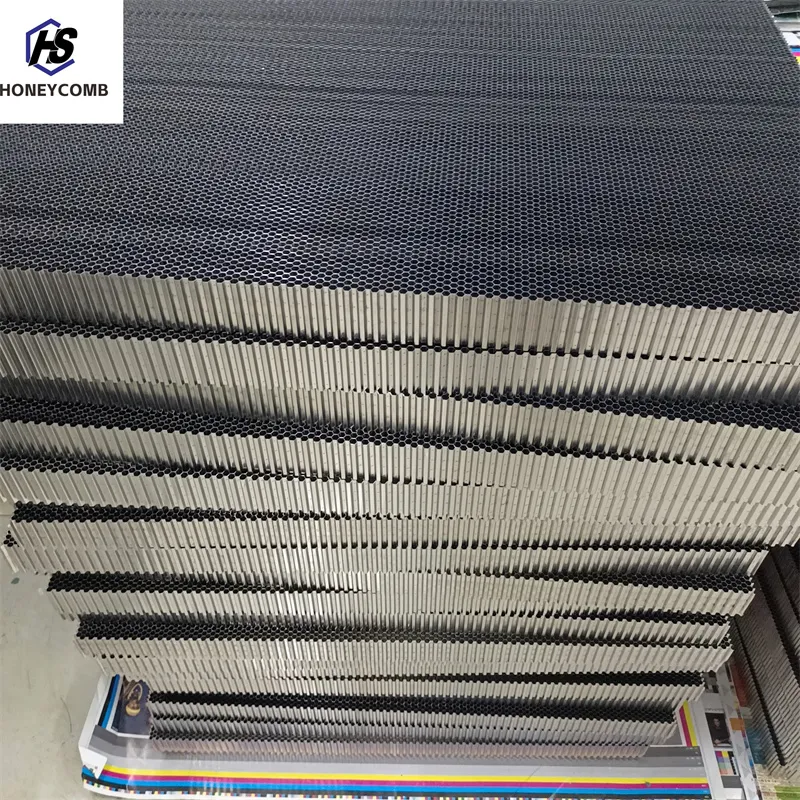

The versatility and efficacy of the honeycomb flow straightener make it an essential component across a broad spectrum of industries, where precise fluid control is non-negotiable. In the aerospace sector, particularly in wind tunnel testing, these straighteners are crucial for generating uniform airflow over test articles, ensuring that aerodynamic measurements are accurate and repeatable. Without them, the turbulent entry conditions would compromise the validity of experimental data, leading to flawed designs. Similarly, in HVAC systems, they optimize air distribution in large ducts, preventing localized hot or cold spots, improving energy efficiency, and enhancing indoor air quality. In power generation, specifically in gas turbines and power plants, honeycomb structures are used to ensure uniform airflow into combustion chambers, leading to more efficient fuel combustion, reduced NOx emissions, and prolonged turbine lifespan. The ability to achieve laminar flow significantly reduces the energy required to move fluids, translating directly into substantial energy savings for industrial operations.

Figure 3: Typical application of a honeycomb flow straightener in an industrial duct.

Furthermore, in the oil and gas industry, honeycomb flow straighteners play a vital role in flow metering applications, ensuring that flow measurement devices receive a stable and swirl-free fluid stream, thereby drastically improving the accuracy of volumetric and mass flow measurements. This accuracy is critical for custody transfer and process control, directly impacting revenue and operational efficiency. In chemical processing, they are utilized in reaction vessels and mixing tanks to promote uniform mixing and mass transfer, which can accelerate reaction rates and improve product yield. The inherent corrosion resistance of Stainless Steel 304 and 316L ensures that these straighteners can withstand harsh chemical environments, extending their service life and reducing the frequency of replacements. Beyond their primary function of flow conditioning, these devices also contribute to enhanced process control by providing stable flow conditions for sensors and control valves. Their robust design minimizes maintenance needs, offering a reliable, long-term solution that consistently delivers improved operational efficiency, reduced energy consumption, and superior process outcomes across a multitude of high-stakes industrial environments.

Selecting the Right Solution: Customization, Quality Assurance, and Industry Standards

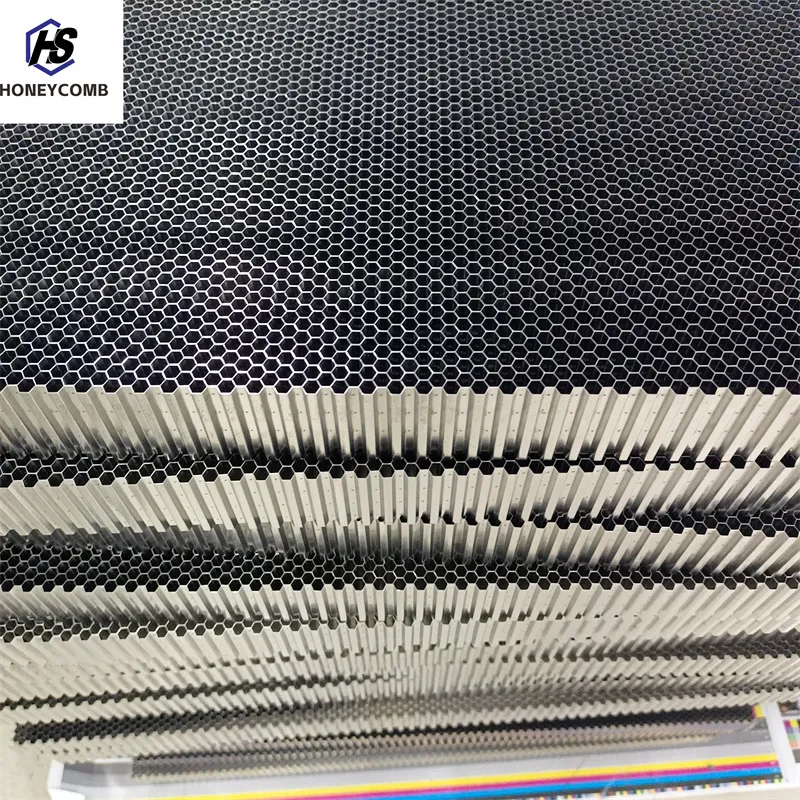

Choosing the appropriate honeycomb flow straightener involves more than just selecting a standard product; it often requires a tailored approach to meet specific application demands. Customization options are extensive, encompassing variations in overall dimensions (diameter, length), cell configurations (cell size, aspect ratio), and material grades (Stainless Steel 304, 316L, and other alloys for highly specialized needs). For instance, an application requiring minimal pressure drop might opt for a larger cell size and shorter length, while an application demanding extremely high flow uniformity, like a calibration test bench, would necessitate a smaller cell size and a longer aspect ratio. Manufacturers must be capable of producing straighteners with precise tolerances to ensure optimal performance, which often involves advanced fabrication techniques such as CNC machining and specialized welding processes. The ability to provide bespoke solutions, coupled with robust engineering support, is a hallmark of a reliable supplier. This consultative approach ensures that the client receives a product perfectly matched to their operational parameters, guaranteeing maximum efficiency and effectiveness in their systems.

Figure 4: Examples of custom-engineered honeycomb flow straighteners.

Quality assurance is paramount in the manufacturing of flow straighteners. Reputable manufacturers adhere to rigorous quality management systems, typically certified to ISO 9001 standards, ensuring consistent product quality from raw material sourcing to final inspection. This includes comprehensive material traceability, strict process controls, and multi-stage inspections. Performance validation is often conducted in accordance with relevant industry standards, such as those set by API (American Petroleum Institute) for oil and gas applications, or specific standards for fluid dynamics testing. This involves not only dimensional checks but also performance tests such as pressure drop measurements, flow visualization studies, and turbulence intensity profiling in dedicated test rigs. When evaluating manufacturers, it's crucial to look for evidence of such certifications, long-standing industry presence, and a proven track record of delivering reliable products. While direct manufacturer comparison by name is outside the scope, key differentiators include the breadth of customization options, adherence to international quality standards, depth of engineering expertise, and verifiable performance data. A transparent approach to quality control and a commitment to meeting strict industry specifications are non-negotiable attributes for any trusted provider of advanced honeycomb flow straightener solutions.

Trust and Reliability: Client Successes and Comprehensive Support

The true measure of a high-quality honeycomb flow straightener lies in its proven ability to deliver consistent performance and value in real-world industrial settings. We have a robust history of successful deployments across various sectors. For example, in a major petrochemical plant, the integration of custom-designed Stainless Steel 316L flow straighteners upstream of critical flow meters significantly improved measurement accuracy by over 15%, leading to more precise chemical dosing and reduced raw material waste, directly impacting the bottom line. Another case involved a large-scale HVAC system for a commercial complex, where the installation of our honeycomb straighteners resulted in a documented 10% reduction in fan energy consumption due to the elimination of turbulent flow patterns and a more uniform air distribution, leading to considerable operational savings and improved comfort. These successes are often highlighted in client feedback, emphasizing the reliability, durability, and performance consistency of our products, and the tangible benefits they bring to complex engineering challenges. Our long-standing relationships with industry leaders, some spanning over a decade, underscore the trust placed in our solutions.

Figure 5: High-precision honeycomb flow straightener units awaiting dispatch.

To further build confidence and ensure peace of mind, we provide comprehensive customer support and clear commitments. Our frequently asked questions (FAQs) address common concerns regarding product selection, installation, and maintenance, providing immediate access to critical information. For instance, questions about ideal cell size versus pressure drop are explained with practical guidelines, or how to properly integrate a honeycomb flow straightener into existing pipework. Our typical delivery cycle for standard products ranges from 2-4 weeks, with expedited options available for urgent requirements, while custom orders are quoted individually based on complexity and volume. We stand by the quality of our products with a robust warranty commitment, typically covering manufacturing defects and material integrity for an extended period, reflecting our confidence in the longevity and performance of our Stainless Steel 304/316L honeycomb cores. Beyond the sale, our dedicated technical support team is available to assist with specific application queries, troubleshooting, and post-installation support, ensuring that our clients maximize the value from their investment and maintain optimal system performance throughout the lifespan of the honeycomb flow straightener.

Frequently Asked Questions (FAQ)

- What material is best for high-corrosion environments?

Stainless Steel 316L is highly recommended due to its enhanced resistance to pitting and crevice corrosion, particularly suitable for marine, chemical, and acidic environments. - How does cell size affect performance?

Smaller cell sizes (e.g., 3.2mm) generally provide superior flow straightening and higher turbulence reduction, but result in a slightly higher pressure drop. Larger cell sizes (e.g., 12.7mm) offer lower pressure drop but less effective straightening. - What is the typical lifespan of a stainless steel honeycomb straightener?

Under normal operating conditions and with appropriate material selection, a Stainless Steel 304/316L honeycomb flow straightener can last for 15-20 years or more, thanks to its durable construction and corrosion resistance. - Can these straighteners be customized for specific dimensions or shapes?

Yes, highly customizable options are available for various diameters, lengths, cell sizes, and even non-circular shapes to perfectly fit unique ducting or equipment requirements.

Conclusion: Pioneering Flow Management with Advanced Honeycomb Technology

The Stainless Steel 304/316L honeycomb flow straightener stands as a testament to precision engineering in fluid dynamics, offering an indispensable solution for achieving laminar flow and optimizing system performance across critical industrial sectors. From enhancing the accuracy of flow measurements in petrochemical plants to improving energy efficiency in HVAC systems and ensuring precise aerodynamic testing in wind tunnels, its impact is far-reaching. The meticulous manufacturing process, combined with the inherent benefits of high-grade stainless steel, guarantees a product that delivers superior durability, exceptional corrosion resistance, and consistent performance over an extended operational life. By transforming chaotic turbulent flows into predictable laminar streams, these devices significantly reduce pressure drop, minimize energy consumption, and safeguard downstream equipment from excessive wear, leading to substantial long-term cost savings and improved operational reliability. The ability to customize cell configurations, dimensions, and material grades further ensures that these advanced flow straighteners can be precisely tailored to meet the unique demands of virtually any industrial application.

In an era where industrial efficiency, environmental compliance, and operational precision are paramount, investing in high-quality flow conditioning solutions like the honeycomb flow straightener is not merely an upgrade but a strategic imperative. Our commitment to adhering to stringent international standards, coupled with comprehensive technical support and a customer-centric approach, ensures that businesses receive not just a product, but a complete solution designed to optimize their fluid management systems. The proven track record, backed by robust client success stories and an unwavering dedication to quality, solidifies the position of stainless steel honeycomb core technology as a cornerstone for advanced flow control. As industries continue to evolve and demand greater precision and efficiency, the role of these sophisticated flow straighteners will only grow, underscoring their significance in shaping the future of fluid dynamics management.

References

- Fluid Dynamics: Fundamental Concepts and Applications in Engineering.

- Turbulence Reduction Techniques and Their Impact on Energy Efficiency.

- The Role of Honeycomb Structures in Enhancing Flow Uniformity for Industrial Processes.

- Advanced Materials for Corrosive Environments: A Comparative Study of Stainless Steel Grades.

- Quality Control and Performance Testing Methodologies for Flow Conditioning Devices.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025