- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

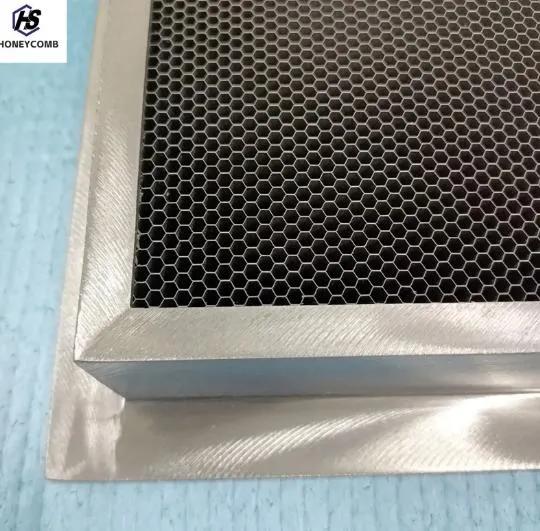

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and Protection

With rising demand for high-performance shielding materials, panel inox me huall mjalti has become the go-to solution for engineers and facility managers seeking superior structural integrity, advanced vibration control, and electromagnetic interference (EMI) protection.

The Role of Honeycomb Aperture in Stainless Steel Honeycomb Panel Shielding

A defining advantage of the panel inox me huall mjalti lies in its customizable honeycomb aperture size. The aperture, or the diameter of each cell, plays a critical role in determining its shielding effectiveness. When a smaller aperture is selected, especially in precision applications such as aerospace, laboratories, or telecom centers, the rrjetë huall mjalti prej çeliku inox performs better at blocking high-frequency electromagnetic waves. Conversely, larger apertures favor applications where ventilation is equally important as shielding, such as HVAC filter systems or data center airflow walls.

The balance between the mechanical rigidity and the electromagnetic shielding offered by the fletë huall mjalti inox makes it ideal for scenarios that demand both structural and electronic performance. Unlike aluminum alternatives, stainless steel offers superior corrosion resistance and durability, making it suitable for more demanding environments.

Why Data Centers Depend on Stainless Steel Honeycomb Panel

Data centers face growing threats from both mechanical vibrations and EMI radiation. The panel inox me huall mjalti provides a reliable solution by serving dual functions: physical protection and EMI attenuation. Its cellular core diffuses waves and vibrations across a wide surface area, effectively minimizing equipment interference and ensuring signal clarity.

Compared with perforated panels or mesh-based systems, rrjetë huall mjalti prej çeliku inox ensures a higher shielding efficiency due to its seamless design and denser cellular structure. In mission-critical IT infrastructures, even slight fluctuations in performance due to interference can lead to significant data errors. That’s why data centers across industries are increasingly integrating fletë huall mjalti inox configurations into server room walls, rack enclosures, and cooling systems.

Beyond shielding, the high airflow capacity of panel inox me huall mjalti contributes to better thermal management—an essential aspect of modern data environments. These panels promote a stable internal temperature, further protecting sensitive electronic components.

Anti-Vibration Benefits of Stainless Steel Honeycomb Sheet in Transportation and Aerospace

Another vital feature of the panel inox me huall mjalti is its anti-vibration and shock-resistance properties. Thanks to its hexagonal cell configuration, it can absorb and distribute kinetic energy efficiently. This makes the fletë huall mjalti inox an excellent fit for aircraft cabins, railway interiors, and high-speed vehicle panels, where weight must be kept low without compromising strength.

In applications where the panels are exposed to dynamic stress—such as during aircraft takeoff or road transportation—the rrjetë huall mjalti prej çeliku inox works as a buffer layer, reducing vibration transfer to adjacent structures. Not only does this preserve the lifespan of surrounding components, but it also enhances the comfort and safety of passengers.

Because the panel inox me huall mjalti can be manufactured in various thicknesses and bonded with face sheets like stainless steel or aluminum, it offers extensive versatility in both functional and decorative installations.

Stainless Steel Honeycomb Panel vs. Traditional Shielding Materials

In terms of performance, the panel inox me huall mjalti surpasses most conventional shielding materials. It outperforms perforated aluminum panels in terms of mechanical strength, shielding performance, and longevity. Unlike fabrics or foils, rrjetë huall mjalti prej çeliku inox doesn't degrade over time, even in high-temperature or humid environments.

Installation is another area where fletë huall mjalti inox shines. Its lightweight structure, despite its robust build, makes it easier to install in ceiling panels, enclosure doors, and even temporary shielding barriers. It’s also fire-resistant, non-combustible, and resistant to most chemicals—qualities that make it suitable for laboratories, clean rooms, and industrial facilities.

Cost-wise, while the panel inox me huall mjalti may carry a higher upfront investment than simpler materials, its long service life and minimal maintenance costs provide significant ROI in the long term. Plus, many industries now prioritize performance over initial cost, further driving the popularity of these advanced panels.

Stainless Steel Honeycomb Panel FAQs

What is the ideal honeycomb aperture size for EMI shielding?

For high-frequency EMI protection, a smaller honeycomb aperture (typically under 3 mm) is preferred. The denser structure of the panel inox me huall mjalti limits the passage of electromagnetic waves more effectively.

How does stainless steel compare to aluminum in honeycomb panels?

Stainless steel is more corrosion-resistant and provides better mechanical strength than aluminum. While aluminum is lighter, fletë huall mjalti inox is more durable and stable under extreme conditions.

Is the stainless steel honeycomb mesh customizable for shape and size?

Yes, most manufacturers offer customizable shapes, thicknesses, and even bonding options for rrjetë huall mjalti prej çeliku inox, making it suitable for specific architectural or industrial requirements.

Can stainless steel honeycomb panel be used outdoors?

Absolutely. Thanks to its excellent weather and corrosion resistance, panel inox me huall mjalti performs well outdoors in various environmental conditions, including rain, snow, and salt air.

What industries benefit most from stainless steel honeycomb sheet?

Industries such as aerospace, telecommunications, data centers, defense, and transportation make the most use of fletë huall mjalti inox for shielding, structural support, and vibration control.

Kategoritë e produkteve

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsLajmeJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsLajmeJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionLajmeJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsLajmeJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsLajmeJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlLajmeJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceLajmeJul.11,2025