- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Januari . 09, 2025 11:47

Back to list

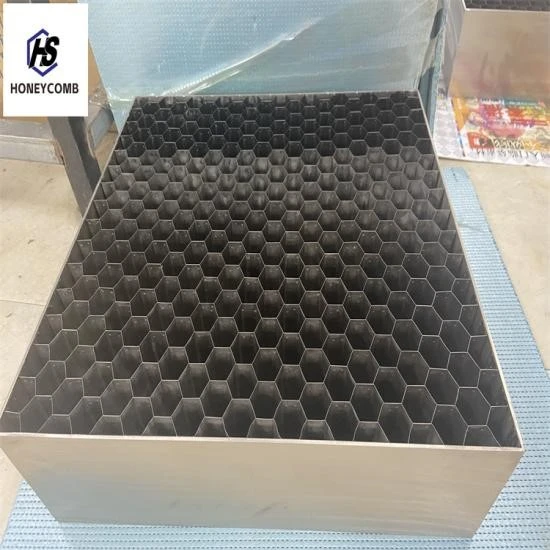

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

Aluminium honeycomb panels are revolutionizing the world of modern construction and design with their remarkable properties. These innovative products, composed of interconnected hexagonal cells, mimic the natural structure found in beehives, delivering an extraordinary balance of strength, flexibility, and weight efficiency. Their application across various industries stands as a testament to their undeniable effectiveness and versatility.

Trustworthiness in the use of aluminium honeycomb panels is also bolstered by their sustainable attributes. Given the growing emphasis on environmental responsibility, these panels offer an eco-friendly option. Aluminium is a recyclable material, and the honeycomb structure requires minimal raw materials, reducing waste and carbon footprint. Furthermore, these panels offer excellent thermal and acoustic insulation properties, contributing further to energy efficiency in buildings. Practical applications extend beyond aerospace and construction into fields like automotive, marine, and even product packaging, highlighting the versatility and indispensable nature of aluminium honeycomb panels. Their rigidity ensures the safety and protection of valuable goods against external shocks and vibrations during transit. In summary, cell aluminium honeycomb panels are pivotal in modern engineering and architecture, providing high performance, reliability, and sustainability. Their continued evolution and adaptation to new technologies promise even greater efficiencies and innovations in the future, consistent with global trends towards lightweight, sustainable design solutions. These panels offer a compelling choice for professionals seeking to harness their distinctive qualities, ensuring their projects stand resilient and efficient in a competitive world.

Trustworthiness in the use of aluminium honeycomb panels is also bolstered by their sustainable attributes. Given the growing emphasis on environmental responsibility, these panels offer an eco-friendly option. Aluminium is a recyclable material, and the honeycomb structure requires minimal raw materials, reducing waste and carbon footprint. Furthermore, these panels offer excellent thermal and acoustic insulation properties, contributing further to energy efficiency in buildings. Practical applications extend beyond aerospace and construction into fields like automotive, marine, and even product packaging, highlighting the versatility and indispensable nature of aluminium honeycomb panels. Their rigidity ensures the safety and protection of valuable goods against external shocks and vibrations during transit. In summary, cell aluminium honeycomb panels are pivotal in modern engineering and architecture, providing high performance, reliability, and sustainability. Their continued evolution and adaptation to new technologies promise even greater efficiencies and innovations in the future, consistent with global trends towards lightweight, sustainable design solutions. These panels offer a compelling choice for professionals seeking to harness their distinctive qualities, ensuring their projects stand resilient and efficient in a competitive world.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025