- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Optimizing Airflow and Testing Efficiency with Honeycomb Technology

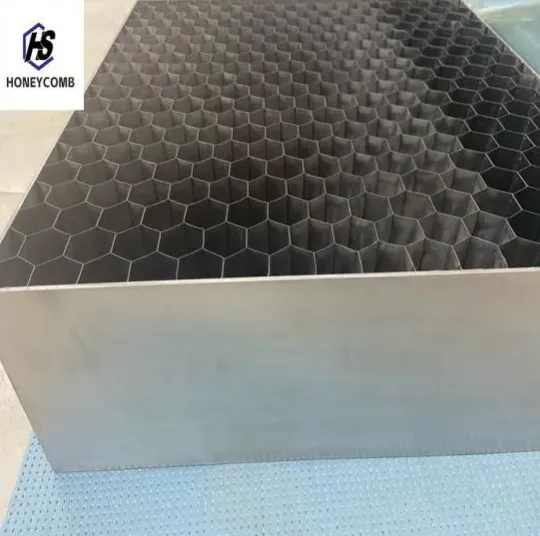

In the realm of aerospace engineering, honeycomb wind tunnels have become indispensable for conducting precise aerodynamic testing. These tunnels are equipped with honeycomb air flow straighteners, which help create a smooth and uniform airflow necessary for simulating real-world conditions. The use of honeycomb technology in wind tunnels not only enhances airflow efficiency but also improves the accuracy of test results, making them essential for testing aircraft designs, vehicles, and other high-performance machinery.

Honeycomb wind tunnels are designed to simulate a variety of wind conditions to assess the performance of various structures, from aircraft wings to automotive designs. By utilizing njia ya upepo ya sega la asali systems, engineers can gather valuable data on the aerodynamic properties of different designs, ensuring safety, performance, and efficiency in their final products.

Honeycomb Blinds Installation: Perfecting Ventilation in Industrial Spaces

Honeycomb blinds installation is a highly effective solution for managing airflow and optimizing ventilation in both commercial and industrial spaces. These blinds are crafted using honeycomb materials, offering superior insulating properties that help maintain energy efficiency. With their unique cellular design, honeycomb blinds allow for the regulation of airflow while also providing a high level of light diffusion, making them an ideal choice for spaces that require controlled lighting and temperature regulation.

The installation of honeycomb blinds ensures that buildings stay comfortable and energy-efficient by controlling both air and light flow. This system helps maintain the desired environmental conditions in spaces such as offices, factories, and laboratories, contributing to better air quality and energy savings.

Air Flow Straightener: Enhancing Airflow Efficiency in High-Performance Systems

The kiboresha mtiririko wa hewa plays a crucial role in applications that require precise control over airflow. These devices use honeycomb technology to reduce turbulence and direct air in a smooth and uniform manner. By incorporating honeycomb air flow straighteners, industries can ensure that airflow is controlled to optimize system performance, particularly in environments like HVAC systems, aerospace testing, and industrial ventilation.

Matumizi ya honeycomb air flow straighteners in systems such as wind tunnels, ventilation ducts, and aerodynamic testing facilities guarantees the accuracy and efficiency of airflow measurement, which is vital for both design and operational purposes. These straighteners are integral in creating a steady airflow, improving the accuracy of testing and the longevity of the systems involved.

Air Straightener Honeycomb: A Key Component for Precision Airflow

The hewa straightener asali is a specialized component used to enhance airflow efficiency in various applications, from industrial ventilation to aerospace testing. By utilizing honeycomb air flow straighteners, this component effectively reduces airflow turbulence, ensuring that air moves in a controlled, laminar flow. The hewa straightener asali structure is especially critical in wind tunnels, where precise airflow is necessary for accurate aerodynamic testing.

Designed to meet the rigorous demands of high-performance testing environments, the hewa straightener asali enables the smooth and uniform distribution of air, facilitating the most accurate results in scientific studies and engineering tests. This makes it a vital tool in industries such as aerospace, automotive, and HVAC.

Wind Tunnel Honeycomb: A Solution for Accurate Aerodynamic Testing

Wind tunnel honeycomb systems are designed to create the ideal conditions for testing aerodynamic properties. These systems incorporate honeycomb air flow straighteners to ensure smooth, uniform airflow, eliminating turbulence that could affect the accuracy of test data. By using njia ya upepo sega la asali technology, engineers can simulate realistic wind conditions and obtain precise measurements for aircraft, vehicles, and other structures.

Whether it's for testing new aircraft designs or simulating the effects of high-speed winds on vehicle bodies, njia ya upepo sega la asali technology provides the essential infrastructure needed to perform these complex tests. The use of honeycomb materials ensures that wind tunnels provide consistent, controlled airflow, making them an indispensable part of the research and development process in industries that rely on aerodynamic testing.

Honeycomb Air Flow Straightener FAQs

What is the role of a honeycomb air flow straightener?

A honeycomb air flow straightener is used to reduce airflow turbulence, ensuring that air moves in a smooth, controlled manner. This technology is especially useful in wind tunnels, industrial HVAC systems, and aerospace testing, where precise airflow is essential for accurate measurements and optimal performance.

How does a honeycomb wind tunnel contribute to aerodynamic testing?

A njia ya upepo ya sega la asali creates a controlled, uniform airflow that is necessary for simulating real-world wind conditions. This enables engineers to test the aerodynamic properties of various designs, such as aircraft and vehicles, and gather accurate data for performance optimization.

What are the benefits of honeycomb blinds installation?

Honeycomb blinds installation provides superior insulation and airflow control. The honeycomb structure helps maintain energy efficiency by regulating both air and light flow, making them ideal for commercial and industrial spaces where temperature and lighting control is crucial.

Why are honeycomb air flow straighteners important for wind tunnel testing?

Honeycomb air flow straighteners are crucial for wind tunnel testing as they ensure smooth, laminar airflow. By reducing turbulence, they help improve the accuracy of aerodynamic tests, enabling engineers to gather precise data for design improvements.

What is the difference between honeycomb air straighteners and traditional straighteners?

Unlike traditional air straighteners, honeycomb air straighteners use a cellular structure to direct air in a uniform flow, significantly reducing turbulence. This results in more efficient airflow control, making them ideal for applications such as wind tunnels, HVAC systems, and aerospace testing.

Kategoria za bidhaa

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsHabariJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionHabariJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsHabariJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionHabariJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsHabariJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsHabariJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlHabariJul.11,2025