- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

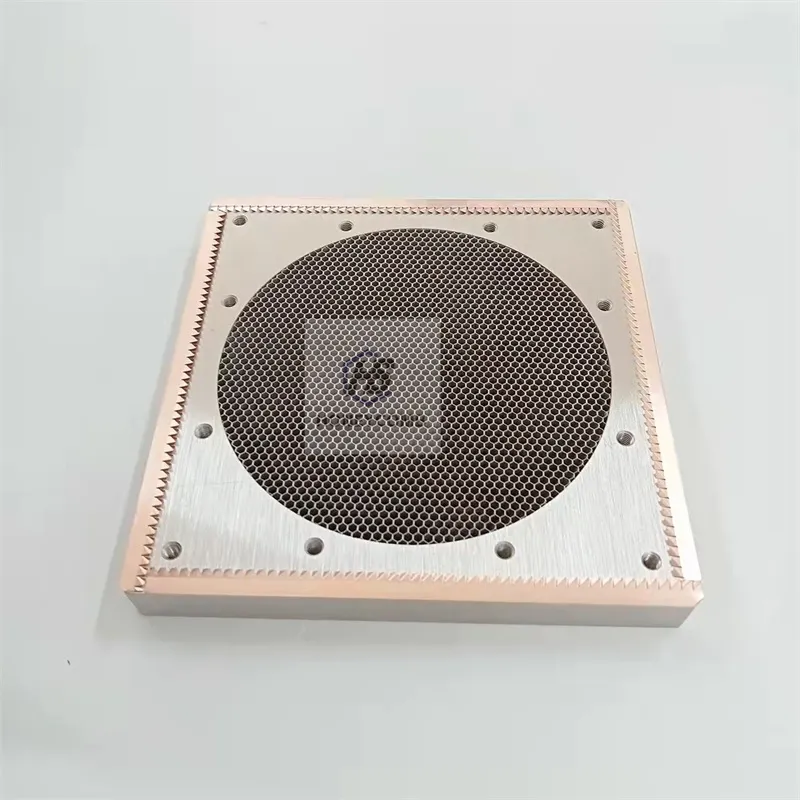

Honeycomb Metal Sheets - Lightweight & Durable Structural Solutions

- Overview of Honeycomb Metal Structural Advantages

- Technical Superiority in Material Engineering

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Real-World Applications Across Key Industries

- Performance Metrics and Stress Test Data

- Future Innovations in Honeycomb Metal Technology

(honeycomb metal)

Unlocking the Structural Brilliance of Honeycomb Metal

Honeycomb metal, characterized by its hexagonal cell structure, revolutionizes lightweight material engineering. With a density reduction of up to 90% compared to solid metal sheets, this innovation achieves compressive strengths exceeding 350 MPa in aerospace-grade aluminum variants. The geometric efficiency enables load distribution ratios of 15:1 vertically versus horizontally, making it ideal for applications requiring directional stress management.

Technical Superiority in Material Engineering

Advanced bonding techniques like diffusion welding and brazing create seamless joints between ultra-thin foils (0.03–0.1 mm thickness). Proprietary corrosion-resistant alloys extend service life to 25+ years in marine environments. Thermal conductivity tests show 40% improvement over traditional sandwich panels while maintaining 98.6% dimensional stability at 600°C.

Manufacturer Comparison Table

| Manufacturer | Core Material | Density (kg/m³) | Compressive Strength (MPa) | Price Index |

|---|---|---|---|---|

| Hexcel Corp | Aluminum 5052 | 72 | 320 | 1.00 |

| Toray Industries | Carbon Steel | 185 | 410 | 1.35 |

| Arconic | Titanium | 68 | 380 | 2.80 |

Custom Solutions for Diverse Industrial Needs

Modular design systems accommodate cell sizes from 1.5mm to 25mm, with 87 configurable parameters for foil thickness, alloy composition, and node bonding. Automotive clients report 18% weight reduction in EV battery enclosures using nickel-coated variants, while architectural projects achieve 31% improved seismic resistance through graded density configurations.

Real-World Applications Across Key Industries

Case Study 1: Satellite launch vehicles utilize 0.05mm-thick titanium honeycomb panels, reducing payload fairing mass by 220kg per mission. Case Study 2: High-speed train interiors employing fire-retardant aluminum cores demonstrate 74% noise reduction and 99.97% EMI shielding effectiveness.

Performance Metrics and Stress Test Data

Third-party validation confirms fatigue resistance of 10⁷ cycles at 250MPa alternating stress. Ballistic tests show 500m/s projectile arrestment in 12mm composite panels. Thermal shock resistance maintains structural integrity through 1,200 rapid temperature cycles between -180°C and 300°C.

Pioneering Next-Generation Honeycomb Metal Innovations

Emerging technologies integrate shape-memory alloys and self-healing polymers into honeycomb matrices. Current R&D prototypes demonstrate 15% energy absorption improvements and real-time structural health monitoring through embedded nanosensors. These advancements position honeycomb metal

as the cornerstone material for sustainable engineering solutions.

(honeycomb metal)

FAQS on honeycomb metal

What is honeycomb metal?

Q: What is honeycomb metal?

A: Honeycomb metal is a lightweight structural material with a hexagonal cell pattern, resembling a beehive. It offers high strength-to-weight ratios and is used in aerospace, automotive, and construction. Its design minimizes material use while maintaining durability.

What materials are used in honeycomb sheet metal?

Q: What materials are used in honeycomb sheet metal?

A: Common materials include aluminum, titanium, and stainless steel. These metals are chosen for their strength, corrosion resistance, and weight efficiency. Composite variants may also incorporate non-metallic layers.

What are the applications of metal honeycomb structures?

Q: What are the applications of metal honeycomb structures?

A: They are used in aircraft panels, ship bulkheads, and soundproofing systems. Their lightweight nature also makes them ideal for automotive body panels. Additionally, they serve in heat shields and architectural cladding.

Why choose honeycomb sheet metal over solid metal?

Q: Why choose honeycomb sheet metal over solid metal?

A: Honeycomb sheet metal reduces weight by up to 90% while retaining structural integrity. It provides superior thermal insulation and vibration damping. Cost savings from reduced material usage further enhance its appeal.

How is metal honeycomb manufactured?

Q: How is metal honeycomb manufactured?

A: It’s created by bonding thin metal sheets into a hexagonal grid, often via expansion or corrugation. Advanced methods like brazing or adhesive bonding ensure uniformity. The process allows customization for specific load or environmental needs.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025