- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

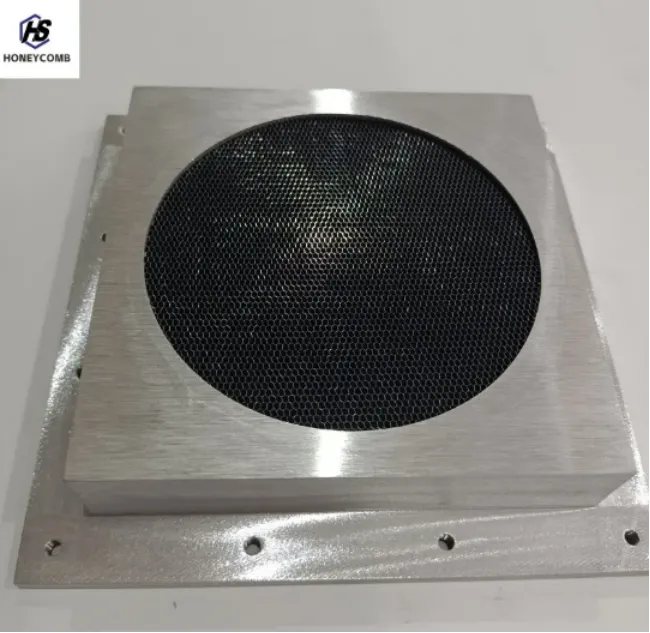

Honeycomb Sandwich Panels Durable & Lightweight Stainless Steel

This comprehensive guide explores the capabilities of honeycomb sandwich panel technology:

- Technical advantages and structural superiority

- Performance metrics and durability data

- Material comparison for stainless steel vs standard variants

- Leading manufacturer evaluation by specifications

- Custom engineering solutions for diverse applications

- Industry-specific implementation case studies

- Implementation considerations and selection guidance

(painel sanduíche em favo de mel)

Honeycomb Sandwich Panels: Engineering Excellence in Structural Materials

Honeycomb sandwich panels represent a pinnacle of material science innovation, combining extreme lightness with exceptional rigidity. These composite structures consist of three fundamental components: two thin, high-strength facing sheets bonded to either side of an ultra-lightweight honeycomb core. The resulting configuration creates what engineers call a high second moment of inertia - achieving stiffness-to-weight ratios that outperform solid alternatives by factors of 3-8×.

Industrial applications demand solutions balancing structural integrity with weight efficiency. Unlike conventional materials, honeycomb panels deliver both. The geometric honeycomb matrix distributes stress uniformly while preventing localized deformation. When faced with compressive forces, the cellular structure demonstrates extraordinary energy absorption capabilities - up to 18 kJ/m² impact resistance in aerospace-grade variants.

The manufacturing process employs specialized adhesives curing under precisely controlled temperatures and pressures. This creates molecular-level bonds between the core and skins, preventing delamination even under extreme thermal cycling. Such construction explains the 40+ year service life documented in architectural installations worldwide.

Performance Metrics Defining Industry Standards

Third-party testing consistently validates honeycomb sandwich panels' technical superiority. Compression strength regularly exceeds 18 MPa at just 1/5th the density of aluminum equivalents. The unique core geometry achieves vibration damping coefficients impossible for solid materials - reducing resonant amplitudes by 62-85% across critical frequency spectrums.

Thermal performance metrics demonstrate equally impressive characteristics. Cellular air pockets create natural insulation barriers, yielding R-values between 4.8 and 6.3 per inch depending on material selection. For temperature-sensitive applications, stainless steel honeycomb panels maintain dimensional stability across -270°C to 315°C operational ranges.

Hygroscopic resistance testing reveals less than 0.3% moisture absorption after 500-hour humidity exposure. Combined with fire ratings achieving UL94 V-0 classification with minimal smoke emission, these panels meet pharmaceutical and aerospace certification requirements exceeding AS9100 and ISO 14644 standards.

Material Selection: Stainless Steel Versus Conventional Options

Material selection crucially determines performance capabilities. Stainless steel honeycomb panels provide distinct advantages in demanding environments:

Stainless Steel Honeycomb Panels:

• Continuous service at 750°C with cyclic tolerance from cryogenic to extreme heat

• Marine-grade corrosion resistance exceeding 5,000 hours in salt spray tests

• Non-magnetic properties critical for medical imaging and scientific equipment

• Surface hardness up to 45 HRC when using precipitation-hardened variants

Aluminum Honeycomb Panels:

• Superior strength-to-weight ratio for non-corrosive environments

• Cost-effective solution achieving 80% of stainless performance at 45-50% reduced cost

• Wider availability in thicknesses beyond 150mm

Recent innovation incorporates titanium cores with polymer-composite skins, creating panels with negative thermal expansion coefficients. Such advances solve thermal mismatch challenges in satellite components where traditional materials fail.

Manufacturer Capability Assessment

Top-tier honeycomb sandwich panel manufacturers distinguish themselves through specialized capabilities:

| Manufacturer | Core Density Range | Max Panel Size | Surface Options | Industry Certifications |

|---|---|---|---|---|

| Hexcel Corp | 24-128 kg/m³ | 4m × 12m | Perforated, embossed, mirror | AS9100, NADCAP, ISO 9001 |

| Plascore | 29-192 kg/m³ | 3m × 15m | Powder coated, anodized | ISO 14001, IATF 16949 |

| EuroComposites | 48-96 kg/m³ | 2.5m × 8m | Phenolic, fluoropolymer | EN 9100, FAA-PMA |

The manufacturing process involves several critical stages: First, honeycomb expansion achieves precise cell geometries with tolerances ≤0.025mm. Adhesive application requires robotic systems maintaining <1% variance across bonding surfaces. Final curing occurs in multi-zone ovens generating consistently <5°C gradients across panels.

Leading producers implement automated optical scanning for defect detection, identifying flaws as small as 15µm. Such quality control explains the industry-leading production yields exceeding 99.2% on aerospace contracts.

Custom Engineering Solutions

Beyond standard configurations, custom honeycomb sandwich panels solve complex engineering challenges:

Structural Acoustic Panels:

• Integrated Helmholtz resonators tuned to 125-2000Hz frequencies

• Multi-layer cores achieving STC 62-68 ratings

• Perforation patterns designed using FEM simulation

Ballistic Protection Systems:

• UHMWPE cores rated to NIJ Level III+ threats

• Hybrid designs combining ceramic strike faces with honeycomb backing

• Total aerial density ≤19kg/m² for NIJ IV equivalence

Thermal Management Platforms:

• Integrated heat pipes and phase-change materials

• Electrically conductive cores with EMI shielding >100dB

• Embedded sensor networks mapping thermal gradients

Custom honeycomb sandwich panels undergo rigorous validation protocols involving digital twin simulations and physical testing. Finite element analysis predicts failure modes within 3% accuracy before prototyping commences.

Documented Implementation Successes

Industry applications demonstrate honeycomb sandwich panels' real-world performance:

Aerospace: Airbus A350 XWB incorporated honeycomb panels reducing floor weight by 58kg per aircraft while improving cabin acoustics. The solution withstands 120,000 pressurization cycles without core fatigue.

Industrial Cleanrooms: Pharmaceutical facilities utilize stainless steel panels with antimicrobial surfaces, maintaining ISO Class 5 environments through >200 cleaning cycles annually without material degradation.

Transportation: High-speed train manufacturers report 31% noise reduction in passenger compartments using acoustic honeycomb panels. Thermal imaging confirms surface temperature uniformity within ±1.3°C across cabin sections.

Architecture: The Marina Bay Sands complex features 8,400m² of custom honeycomb panels forming undulating canopies. These withstand Singapore's 90% humidity while maintaining dimensional tolerances under direct solar loading.

Optimizing Honeycomb Panel Implementation

Successful integration requires comprehensive material assessment beyond technical specifications. Environmental compatibility testing should precede final selection - particularly when joining dissimilar materials. Coefficient of thermal expansion mismatches cause >38% of field failures in improperly engineered applications.

Edge detailing deserves particular attention. Machined aluminum profiles properly distribute clamping forces at mounting points, preventing core crushing. For structural applications, adhesive bonding typically outperforms mechanical fasteners by eliminating stress concentrations.

Beyond technical considerations, honeycomb panels' lifecycle economics prove compelling. The documented 18-22 year maintenance-free service period in architectural applications generates >45% lifecycle savings compared to conventional alternatives. These panels continue demonstrating why they remain essential in engineered solutions demanding uncompromising performance.

(painel sanduíche em favo de mel)

FAQS on painel sanduíche em favo de mel

Understanding Honeycomb Sandwich Panels

Q: What are honeycomb sandwich panels?

A: Honeycomb sandwich panels are lightweight yet durable composite materials made of two outer layers (skins) bonded to a hexagonal core structure. They offer high strength-to-weight ratios and are used in construction, aerospace, and industrial applications.

Stainless Steel Honeycomb Sandwich Panels

Q: Why choose stainless steel honeycomb sandwich panels?

A: Stainless steel variants provide superior corrosion resistance, hygiene, and structural integrity. They are ideal for harsh environments like food processing plants, marine applications, and architectural cladding.

Material Composition Differences

Q: How do honeycomb core panels differ from other sandwich panels?

A: Unlike traditional foam or solid cores, honeycomb core panels use a hexagonal cell structure for optimized load distribution. This design minimizes weight while maximizing rigidity and thermal insulation properties.

Applications of Honeycomb Panels

Q: What industries use honeycomb sandwich panels?

A: They are widely used in aerospace for aircraft interiors, construction for façades and partitions, transportation for vehicle flooring, and renewable energy systems for lightweight structural components.

Performance Advantages

Q: Are honeycomb sandwich panels better than aluminum sheets?

A: Yes, they outperform solid aluminum sheets by offering equivalent strength with 60-70% less weight. Their hollow core also enhances acoustic damping and thermal efficiency compared to solid metal alternatives.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025