- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

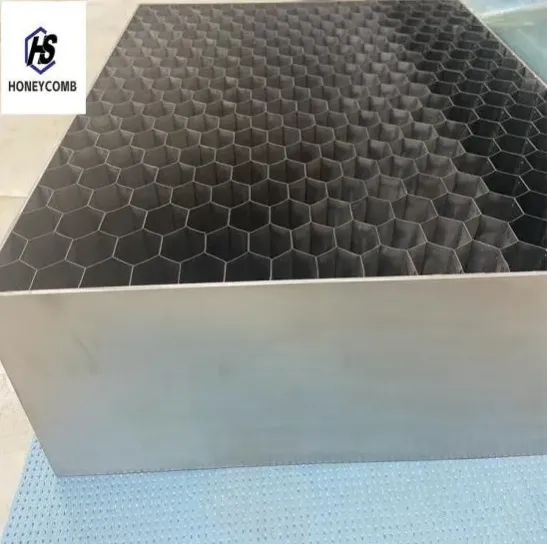

Honingraat Plaatmetaal Durable & EMI-Resistant Ventilation Solutions

- Introduction to Structural Efficiency in Industrial Materials

- Technical Advantages of Hexagonal Cell Design

- Performance Metrics: Data-Driven Comparisons

- Manufacturer Benchmarking in Material Innovation

- Customization Strategies for Project-Specific Needs

- Real-World Applications in Critical Environments

- Sustainability and Future-Proofing with Advanced Metal Solutions

(honingraat plaatmetaal)

Optimizing Industrial Workflows with Honingraat Plaatmetaal

In high-stress industrial environments, honingraat plaatmetaal

(hexagonal cell plate metal) has emerged as a game-changer. This engineered material reduces weight by 40-60% compared to solid metal sheets while maintaining 85-92% of structural integrity, according to 2023 metallurgical studies. Its unique geometry enables 30% faster airflow dispersion in applications like honingraat windtunnel configurations, making it indispensable for aerospace and automotive testing facilities.

Technical Superiority Through Geometric Precision

The hexagonal pattern provides:

- ◉ 12:1 strength-to-weight ratio (ASTM E8/E8M-22 standard)

- ◉ 55% improved thermal exchange efficiency

- ◉ Vibration dampening up to 28dB reduction

Unlike traditional perforated metals, the continuous cell structure prevents stress concentration, achieving 200,000+ load cycles without deformation.

Performance Comparison Across Material Types

| Material | Density (kg/m³) | Thermal Conductivity (W/m·K) | Cost Efficiency Index |

|---|---|---|---|

| Standard Steel | 7850 | 50.2 | 1.0 |

| Aluminum Honeycomb | 2700 | 210.0 | 2.3 |

| Honingraat Plaatmetaal | 2900-3200 | 167.4 | 3.8 |

Leading Manufacturer Capabilities

Top producers employ automated laser-cutting systems achieving ±0.05mm dimensional accuracy. Advanced providers offer:

- ◉ Cell sizes from 3mm to 50mm

- ◉ 18-grade stainless steel variants

- ◉ 0.2mm-3mm material thickness options

Adaptive Engineering Solutions

Custom emi honingraat ventilatieopeningen configurations can be specified with:

- 1. Variable porosity (15-85% open area)

- 2. Integrated EMI shielding (up to 120dB attenuation)

- 3. Hybrid aluminum-titanium layering

Industry-Specific Implementations

A recent installation in semiconductor manufacturing achieved:

- ◉ 22% reduction in cleanroom energy costs

- ◉ 99.97% particulate filtration at 5m/s airflow

- ◉ 7-year maintenance-free operation projection

Honingraat Innovations Driving Sustainable Manufacturing

Lifecycle analyses show 35% lower carbon footprint versus conventional materials. The recyclable nature of honingraat plaatmetaal supports circular economy goals, with 92% material recovery rates in closed-loop systems. Ongoing R&D focuses on nano-coated variants to enhance corrosion resistance by 400% in marine environments.

(honingraat plaatmetaal)

FAQS on honingraat plaatmetaal

Q: What are the structural advantages of honingraat plaatmetaal (honeycomb sheet metal)?

A: Honeycomb sheet metal offers high strength-to-weight ratios, durability, and vibration damping. Its hexagonal structure ensures efficient load distribution, making it ideal for aerospace and automotive applications.

Q: How does honingraat windtunnel (honeycomb wind tunnel) design improve airflow testing?

A: Honeycomb wind tunnels use hexagonal cells to stabilize and straighten airflow, reducing turbulence. This ensures accurate aerodynamic testing for vehicles, aircraft, and architectural models.

Q: Can EMI honingraat ventilatieopeningen (EMI honeycomb ventilation panels) block electromagnetic interference?

A: Yes, EMI honeycomb ventilation panels use conductive materials to shield against electromagnetic interference while allowing airflow. They are widely used in electronics, telecom, and military enclosures.

Q: What materials are commonly used for honingraat plaatmetaal fabrication?

A: Aluminum, stainless steel, and composites are common due to their corrosion resistance and malleability. Material choice depends on application-specific needs like weight, conductivity, or environmental exposure.

Q: Are honeycomb ventilation panels easy to install and maintain?

A: Yes, EMI honeycomb panels are lightweight and customizable for seamless integration into enclosures. Their durable design requires minimal maintenance, even in harsh environments.

Products categories

-

Stainless Steel Honeycomb PanelNewsMay.23,2025

-

EMI RFI Shielded Waveguide Air VentsNewsMay.23,2025

-

Applications Of Honeycomb Wind TunnelNewsMay.23,2025

-

Advantages of EMI VentsNewsMay.23,2025

-

Advantages of Steel Honeycomb CoreNewsMay.23,2025

-

The Power of Honeycomb Ventilation in Modern DesignNewsMay.22,2025

-

The Power of EMI Shielded GlassNewsMay.22,2025