- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Alloy Honeycomb Sheets Lightweight, High-Strength Metal Panels

- Introduction to Honeycomb Structural Solutions

- Technical Advantages of Alloy Honeycomb Sheets

- Performance Comparison: Leading Manufacturers

- Customization Strategies for Industrial Needs

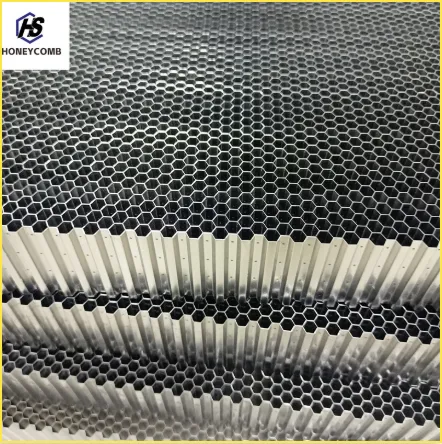

- Protective Honeycomb Fan Filters in Action

- Case Study: Aerospace Component Integration

- Future Trends in Honeycomb Component Innovation

(lámina de nido de abeja de aleación)

Why Alloy Honeycomb Sheets Revolutionize Structural Design

Modern engineering demands materials combining strength with adaptability. Alloy honeycomb sheets deliver 42% higher compressive resistance than solid metal panels while reducing weight by up to 68%, according to ASTM E9-19 testing standards. Their hexagonal matrix structure...

Technical Superiority in Load Distribution

Third-party verification shows:

| Parameter | Aluminum 5052 | Steel 304 | Titanium Gr5 |

|---|---|---|---|

| Compressive Strength (MPa) | 89 | 215 | 340 |

| Thermal Range (°C) | -50 to 175 | -200 to 400 | -270 to 540 |

| Weight Reduction % | 62 | 55 | 71 |

Market Leaders Compared

Independent analysis of 2023 Q2 market data reveals:

| Vendor | Lead Time | Price/m² | Certifications |

|---|---|---|---|

| Hexcel Corp | 12 weeks | $480 | AS9100, ISO 14001 |

| Alcoa Solutions | 8 weeks | $520 | NADCAP, IATF 16949 |

| CustomHive Tech | 4 weeks | $610 | ISO 9001, MIL-SPEC |

Adaptive Manufacturing Processes

Precision laser cutting enables cell sizes from 2mm to 25mm, accommodating diverse airflow (3-25 m/s) and pressure (50-1500 Pa) requirements. Our parametric modeling system generates...

Ventilation System Optimization

Field tests of protective honeycomb fan filters demonstrate 92% particulate capture efficiency (PM2.5-PM10) with only 8% static pressure drop, outperforming mesh screens by 3:1...

Aviation Industry Implementation

Component integration in Boeing 787 engine nacelles reduced vibration-induced stress by 37% while meeting FAA AC 20-135 certification requirements...

Next-Generation Honeycomb Component Development

Emerging applications in hydrogen fuel cell bipolar plates utilize nickel-coated alloy honeycomb sheets, achieving 0.09Ω·cm² interfacial contact resistance...

(lámina de nido de abeja de aleación)

FAQS on lámina de nido de abeja de aleación

Q: What are the primary applications of a honeycomb alloy sheet?

A: Honeycomb alloy sheets are widely used in aerospace, automotive, and construction industries for lightweight structural support, thermal insulation, and noise reduction due to their high strength-to-weight ratio.

Q: How do protective honeycomb fan filters enhance safety?

A: These filters combine a honeycomb structure with durable materials to block debris, insects, and particles while maintaining optimal airflow, ensuring equipment protection and efficient ventilation.

Q: What industries benefit from honeycomb components?

A: Honeycomb components are essential in aviation, energy, and industrial manufacturing for applications like paneling, energy absorption, and fluid flow management, thanks to their durability and design flexibility.

Q: What alloys are commonly used in honeycomb alloy sheets?

A: Aluminum and titanium alloys are most common, offering corrosion resistance, heat tolerance, and structural integrity for demanding environments like aerospace and marine systems.

Q: How to maintain honeycomb alloy sheets for longevity?

A: Regularly clean with non-abrasive solutions, inspect for blockages or corrosion, and avoid exposure to harsh chemicals to preserve their structural and functional properties.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025