- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honeycomb Stainless Steel Air Flow Straightener-Hengshi|Aerodynamic Testing&Airflow Stabilization

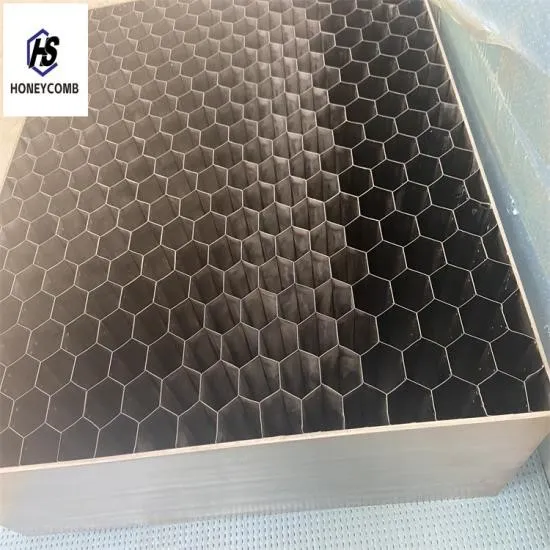

Honeycomb Stainless Steel Air Flow Straightener is a cutting-edge solution designed to enhance aerodynamic testing and airflow management across various industries. Developed by Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd., this product exemplifies the fusion of advanced materials and engineering precision. This article explores its features, technical specifications, applications, and the company’s commitment to quality, supported by authoritative insights from the National Institute of Standards and Technology (NIST).

Product Introduction

The Honeycomb Stainless Steel Air Flow Straightener is a critical component in wind tunnel systems, designed to transform turbulent airflow into laminar flow. This process ensures accurate aerodynamic measurements, making it indispensable for research and development in fields such as aerospace, automotive, and renewable energy. The product’s design leverages the unique properties of stainless steel honeycomb structures, which have been widely utilized for decades to stabilize airflow in high-precision environments.

Key Features and Advantages

The Honeycomb Air Flow Straightener stands out for its ability to maintain airflow stability while minimizing pressure drop. Its thin cell walls create an array of straight passageways, achieving a maximum open area of 95–99%. This design reduces turbulence, ensuring consistent flow rates for accurate data collection. Additionally, the product’s high shielding effectiveness and corrosion resistance make it suitable for harsh environments, as noted in NIST guidelines for material durability in industrial applications [1].1

Technical Specifications

| Material | Carton steel, 304 stainless steel, 316L, Hastelloy X, Haynes 214, Aluminum, Brass, Copper, etc. |

|---|---|

| Foil Thickness | 0.05, 0.07, 0.076, 0.1, 0.13, 0.15, 0.2mm |

| Core Size | 0.8, 1.0, 1.2, 1.6, 2.0, 2.2, 2.4, 2.5, 3.0, 3.2, 4.2, 4.8, 5.0, 5.2, ..., 6.0, 8, 10, 12, 20, 30 mm (customizable) |

| Thickness | Customized |

| Surface Treatment | Painting, white oxygen, Electroless Nickel plating, electrophoresis, powder coating, Brush (as required) |

| Certifications | ISO9001, RoHS |

| Welding Technology | Spot welding, vacuum brazing |

| Function | EMI Shielding, Air Ventilation, Cooling, Corrosion Resistance |

| Applications | EMI shielding vent, flow straightener, railways, marine, aviation & aerospace, wind energy, defense, gas seals, communications, medical, and other industries. |

Applications in Aerodynamic Testing

Wind tunnels are essential tools for studying aerodynamic effects, from aircraft and automobiles to high-speed trains and buildings. The Honeycomb Air Flow Straightener plays a pivotal role in these systems by stabilizing airflow, ensuring precise measurements of air resistance, heat resistance, and pressure resistance. According to NIST’s research on fluid dynamics, such devices are critical for achieving repeatability in experimental data [2].2

Company Background: Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

As a leading manufacturer in the production of high-quality shielding products, Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. specializes in steel honeycomb cores, honeycomb air flow straighteners, and honeycomb seals. The company’s commitment to innovation and quality is reflected in its ISO9001 and RoHS certifications, ensuring compliance with international standards. Hengshi’s products are widely used in aerospace, defense, and renewable energy sectors, where precision and reliability are paramount.

Why Choose Hengshi?

- Advanced Materials: Utilizes stainless steel and other corrosion-resistant alloys for long-term durability.

- Customization: Offers tailored solutions to meet specific project requirements.

- Technical Expertise: Backed by a team of engineers with expertise in aerodynamics and material science.

- Global Standards: Adheres to ISO9001 and RoHS certifications for quality and environmental compliance.

Conclusion

The Honeycomb Stainless Steel Air Flow Straightener by Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. represents a significant advancement in aerodynamic testing technology. Its ability to stabilize airflow with minimal pressure drop, combined with its robust construction and customization options, makes it an ideal choice for industries requiring precision. As NIST continues to set benchmarks for measurement accuracy, products like this ensure that experimental data remains reliable and reproducible [3].3

References

- National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov

- NIST Research on Fluid Dynamics. (n.d.). Retrieved from https://www.nist.gov

- NIST Guidelines for Measurement Accuracy. (n.d.). Retrieved from https://www.nist.gov

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025