- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

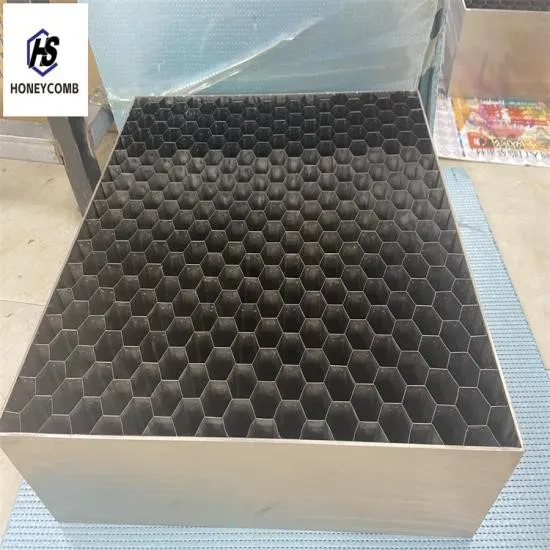

Honeycomb Stainless Steel Air Flow Straightener | Hengshi Precision Machinery

Product Introduction

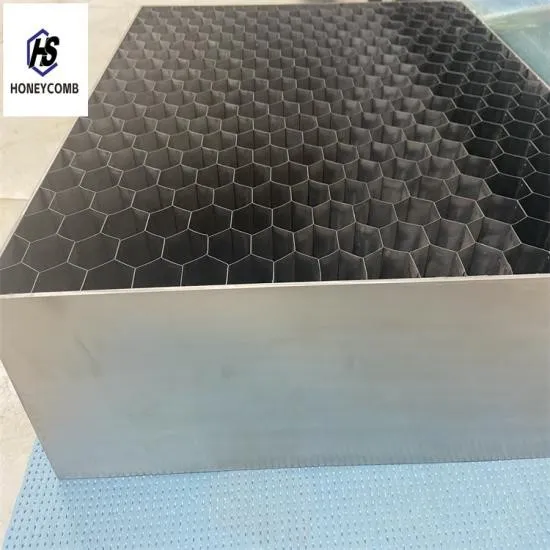

The Honeycomb Stainless Steel Air Flow Straightener is a critical component in aerodynamic research and industrial testing. Designed to stabilize airflow and reduce turbulence, this product ensures accurate measurements in environments where precision is paramount. Its unique honeycomb structure, composed of thin cell walls, creates a highly efficient system for directing airflow while maintaining a minimal pressure drop. This makes it an essential tool for applications ranging from automotive and aerospace engineering to building and marine testing.

Technical Specifications

| Category | Details |

|---|---|

| Material | Carton steel, 304 stainless steel, 316L, Hastelloy X, Haynes 214, Aluminum, Brass, Copper, etc. |

| Foil Thickness | 0.05, 0.07, 0.076, 0.1, 0.13, 0.15, 0.2mm |

| Core Size | 0.8, 1.0, 1.2, 1.6, 2.0, 2.2, 2.4, 2.5, 3.0, 3.2, 4.2, 4.8, 5.0, 5.2, 6.0, 8, 10, 12, 20, 30mm (customizable) |

| Surface Treatment | Painting, white oxygen, Electroless Nickel plating, electrophoresis, powder coating, Brush (as required) |

| Certifications | ISO9001, RoHS |

| Function | EMI Shielding, Air Ventilation, Cooling, Corrosion Resistance |

| Applications | EMI shielding vent, flow straightener, railways, marine, aviation/aerospace, wind energy, defense, gas seals, communications, medical, and other industries. |

Key Features and Advantages

The Honeycomb Air Flow Straightener stands out due to its advanced design and versatility. Here are its primary benefits:

- High Efficiency: With a maximum open area of 95-99%, the honeycomb structure minimizes pressure drop while maintaining laminar airflow, critical for accurate aerodynamic testing.

- Corrosion Resistance: Constructed from stainless steel and other durable materials, it withstands harsh environments, making it ideal for marine and industrial applications.

- Customization: Available in various sizes, thicknesses, and surface treatments, the product can be tailored to meet specific project requirements.

- Multi-Functional: Beyond airflow stabilization, it provides EMI shielding, sound insulation, and ventilation, offering a comprehensive solution for complex systems.

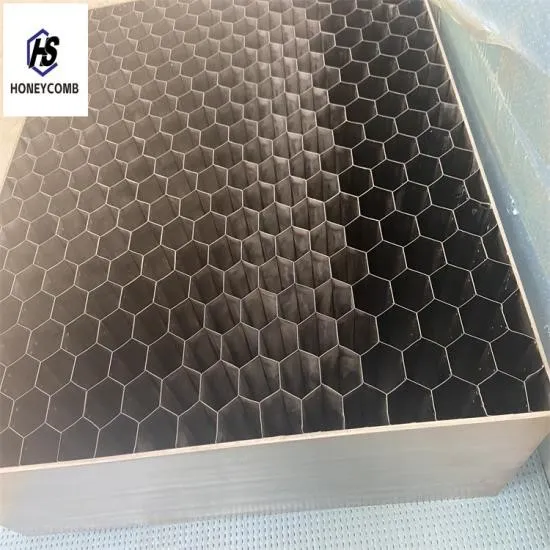

Applications in Aerodynamic Testing

Wind tunnels are essential tools for studying aerodynamic effects, and the Honeycomb Air Flow Straightener plays a pivotal role in these systems. By transforming turbulent airflow into laminar flow, it ensures precise measurements of factors like drag, lift, and pressure distribution. This is particularly vital in the development of:

- Automotive: Testing vehicle aerodynamics to improve fuel efficiency and stability.

- Aerospace: Evaluating aircraft and missile designs for optimal performance and safety.

- Marine: Analyzing hull designs for ships and submarines to reduce resistance and enhance speed.

- Infrastructure: Assessing the structural integrity of buildings and high-speed trains against wind forces.

The product's ability to handle high-speed airflow (from light breezes to hypersonic velocities) makes it adaptable to a wide range of wind tunnel configurations. Its robust construction also ensures durability in high-stress environments, such as those encountered in defense and aerospace testing.

Company Background: Hengshi Precision Machinery

Founded as a leader in precision engineering, Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. specializes in producing high-quality shielding products, including ventilation panels, steel honeycomb cores, and air flow straighteners. With a commitment to innovation and quality, the company serves industries worldwide, providing solutions that meet stringent performance and safety standards.

Hengshi's products are certified under ISO9001 and RoHS, ensuring compliance with international quality and environmental regulations. The company's expertise in advanced materials and manufacturing techniques, such as spot welding and vacuum brazing, enables it to deliver reliable, durable solutions for critical applications.

Industry Standards and Compliance

The Honeycomb Air Flow Straightener adheres to rigorous industry standards, ensuring its effectiveness and safety in diverse applications. While specific standards for honeycomb airflow straighteners may not be universally defined, the principles of aerodynamic testing and material integrity align with guidelines from organizations like the National Institute of Standards and Technology (NIST).

NIST, the U.S. National Metrology Institute, plays a critical role in establishing measurement standards that underpin technological advancements. While the search for "Honeycomb Air Flow Straightener standards NIST" returned an error, NIST's work in areas such as metrology and materials science provides a foundation for the precision and reliability required in aerodynamic testing. By adhering to NIST's principles of accuracy and measurement, Hengshi ensures its products meet the highest levels of quality and performance.

Reference: National Institute of Standards and Technology (NIST)

Conclusion

The Honeycomb Stainless Steel Air Flow Straightener is a versatile and reliable solution for aerodynamic testing and industrial applications. Its advanced design, customization options, and compliance with international standards make it an indispensable tool for engineers and researchers. By partnering with Hengshi Precision Machinery, industries can leverage cutting-edge technology to achieve precision, efficiency, and innovation in their projects.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025