- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

دور قلب خلية النحل الفولاذي في المعدات الصناعية

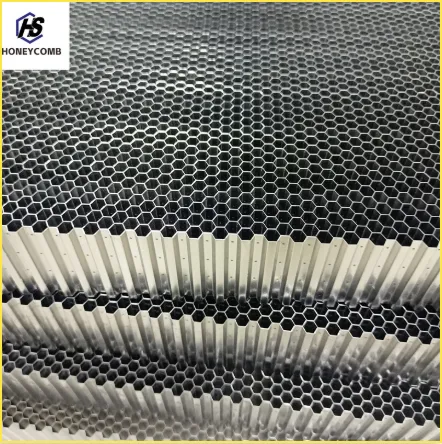

تُعرف أنوية قرص العسل الفولاذية بنسبة قوتها إلى وزنها المذهلة، وهي تُحدث ثورة في طريقة تصميم المعدات الصناعية. قلب عسل فولاذي يتم دمج المواد بشكل متزايد في مكونات الآلات، مما يوفر وفورات كبيرة في الوزن مع الحفاظ على سلامة هيكلية استثنائية. توفر هذه المواد حلاً للصناعات التي تسعى إلى تحسين أداء المعدات دون المساس بالمتانة. ألواح معدنية على شكل قرص العسل ل صفائح فولاذية على شكل قرص العسلويستمر استخدام هذه المواد المتقدمة في النمو بسبب خصائصها الفريدة.

قلب عسل فولاذي لمكونات الآلات خفيفة الوزن

قلب عسل فولاذي تلعب التكنولوجيا دورًا محوريًا في تقليل وزن الآلات الصناعية دون المساس بمتانتها. يتيح الهيكل الفريد للنواة الشبيهة بقرص العسل لها توفير قدرة تحمل فائقة مع خفض الوزن الإجمالي لمكونات الآلات بشكل ملحوظ. يُعدّ هذا التخفيض في الوزن أمرًا بالغ الأهمية في صناعات مثل صناعة الطيران والسيارات والآلات الثقيلة، حيث يُعدّ الأداء وكفاءة استهلاك الوقود من الاعتبارات الرئيسية.

- نسبة عالية من القوة إلى الوزن:واحدة من أهم مزايا قلب عسل فولاذيتتميز بنسبة قوة إلى وزن استثنائية. يسمح تصميمها بإنشاء مكونات خفيفة الوزن ومتينة للغاية، مما يجعلها مثالية للمعدات المستخدمة في التطبيقات الصعبة.

- زيادة الكفاءة:من خلال تقليل وزن مكونات الآلات، نوى قرص العسل الفولاذيةتساهم في الكفاءة العامة للمعدات. تتطلب المكونات الأخف وزنًا طاقة أقل للتحرك، مما يؤدي إلى تحسين كفاءة استهلاك الوقود وخفض تكاليف التشغيل.

صفائح معدنية على شكل قرص العسل للتطبيقات الصناعية

صفائح معدنية على شكل قرص العسل is commonly used in the manufacturing of industrial equipment due to its versatile properties. The combination of lightweight metal sheets and the honeycomb structure results in an ideal material for creating robust machinery components. Whether it’s used for protective casing or internal structural support, صفائح معدنية على شكل قرص العسل يقدم حلاً فعالاً للصناعات التي تحتاج إلى مواد عالية الأداء.

- المتانة والقوة:استخدام صفائح معدنية على شكل قرص العسلفي التطبيقات الصناعية، تضمن متانة المكونات وخفة وزنها. صُممت هذه المادة لتتحمل الاستخدام الشاق مع الحفاظ على سلامتها الهيكلية بمرور الوقت.

- التصنيع الفعال من حيث التكلفة: صفائح معدنية على شكل قرص العسليوفر حلاً اقتصاديًا لإنتاج مكونات آلات خفيفة الوزن دون المساس بالجودة. كفاءته الإنتاجية تُسهم في خفض تكاليف المواد الخام واستهلاك الطاقة ووقت التصنيع.

لوحة قرص العسل المعدنية لضمان سلامة الهيكل

في عالم الآلات الصناعية، تعتبر سلامة البنية أمرًا ضروريًا. ألواح معدنية على شكل قرص العسل تُستخدم هذه الألواح بشكل متزايد لقدرتها على توفير هيكل أساسي مستقر وقوي دون إضافة وزن زائد. تُستخدم هذه الألواح غالبًا في تصنيع قطع الآلات التي تتطلب قوة عالية ووزنًا خفيفًا، مما يجعلها مثالية للآلات الثقيلة ومعدات النقل والأدوات الصناعية.

- تحسين الأداء الهيكلي: ألواح معدنية على شكل قرص العسلصُممت هذه المنتجات لتوفير أقصى أداء هيكلي بأقل استخدام للمواد. تصميمها الفريد يسمح لها بامتصاص القوى وتوزيع الأحمال بفعالية، مما يوفر متانة أكبر لمكونات الآلات.

- تطبيقات متعددة الاستخدامات:من هياكل الطائرات إلى معدات البناء، ألواح معدنية على شكل قرص العسلمتعددة الاستخدامات، ويمكن تصميمها لتناسب مجموعة واسعة من الاحتياجات الصناعية. قدرتها على التكيف تجعلها مادة قيّمة لمختلف مكونات الآلات في مختلف الصناعات.

صفائح فولاذية على شكل قرص العسل للمعدات عالية الأداء

صفائح فولاذية على شكل قرص العسل تُستخدم على نطاق واسع في الصناعات التي يُعد فيها تقليل الوزن والقوة العالية عاملين حاسمين. مرونة صفائح فولاذية على شكل قرص العسل تسمح هذه الألواح بتطبيقها في العديد من مكونات الآلات، بدءًا من الأغلفة الخارجية الواقية ووصولًا إلى الدعامات الهيكلية الداخلية. تُسهم هذه الألواح بشكل كبير في تقليل وزن المعدات مع الحفاظ على أعلى معايير السلامة والمتانة.

- خفيف الوزن ولكنه قوي: صفائح فولاذية على شكل قرص العسلتوفر توازنًا مثاليًا بين القوة والوزن. تصميمها الفريد يضمن أداءً مثاليًا في الآلات الثقيلة، مثل مركبات البناء ومعدات التصنيع.

- كفاءة الطاقة:استخدام صفائح فولاذية على شكل قرص العسليُساعد استخدام الآلات في تحسين كفاءة الطاقة من خلال تقليل الوزن الإجمالي للمعدات. تتطلب الآلات الأخف وزنًا طاقة أقل للتشغيل، مما يُؤدي إلى انخفاض تكاليف التشغيل وتقليل البصمة البيئية.

قلب خلية النحل الفولاذي: نقطة تحول في مجال المعدات الصناعية

التكامل قلب عسل فولاذي لقد أحدثت المواد المستخدمة في المعدات الصناعية نقلة نوعية في مجال التصنيع. فمن خلال توفيرها لوزن فائق دون التضحية بالقوة أو المتانة، أصبحت هذه المواد أساسية في تصميم وبناء الآلات الحديثة. سواءً استُخدمت في ألواح معدنية على شكل قرص العسل للدعم الهيكلي أو صفائح معدنية على شكل قرص العسل بالنسبة للأغلفة خفيفة الوزن، فإن فوائد مواد قرص العسل الفولاذية واضحة.

- المتانة طويلة الأمد: نوى قرص العسل الفولاذيةتوفر متانة طويلة الأمد، مما يضمن بقاء مكونات الآلات في حالة عمل وفعالية لسنوات. هذا العمر الطويل يقلل تكاليف الصيانة ويعزز موثوقية المعدات الصناعية.

- تصميم صديق للبيئة:استخدام قلب عسل فولاذيلا تُسهم المواد المُحسّنة في تحسين كفاءة الآلات فحسب، بل تُسهم أيضًا في نهج تصنيع أكثر استدامة. فمن خلال تقليل وزن الآلات وتحسين كفاءة الطاقة، تُسهم هذه المواد في تقليل البصمة الكربونية للعمليات الصناعية.

دمج قلب عسل فولاذي, ألواح معدنية على شكل قرص العسل، و صفائح معدنية على شكل قرص العسل يُقدم استخدام المواد المُحسّنة في تصميم المعدات الصناعية مزايا عديدة، منها تقليل الوزن، وفعالية التكلفة، وتعزيز سلامة الهيكل. تُساعد هذه المواد الصناعات على تحقيق أهداف أدائها مع تقليل تأثيرها البيئي. اكتشف كيف صفائح فولاذية على شكل قرص العسل يمكن للمواد ذات الصلة أن تعمل على تحسين تصميمات الآلات الخاصة بك اليوم وتدفع عجلة الابتكار المستقبلي في عملياتك الصناعية.

فئات المنتجات

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsأخبارJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionأخبارJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsأخبارJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionأخبارJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsأخبارJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsأخبارJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlأخبارJul.11,2025