- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

El papel del núcleo de panal de acero en los equipos industriales

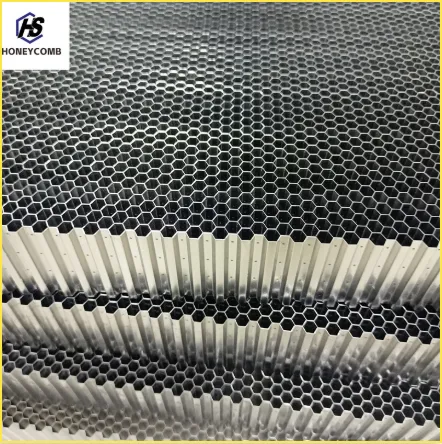

Los núcleos de panal de acero, conocidos por su increíble relación resistencia-peso, están revolucionando la forma en que se diseñan los equipos industriales. Núcleo de panal de acero Los materiales se integran cada vez más en los componentes de maquinaria, lo que ofrece un ahorro de peso sustancial y mantiene una integridad estructural excepcional. Estos materiales ofrecen una solución para las industrias que buscan optimizar el rendimiento de los equipos sin comprometer la durabilidad. paneles metálicos de nido de abeja a láminas de acero en forma de panalEl uso de estos materiales avanzados continúa creciendo debido a sus propiedades únicas.

Núcleo de panal de acero para componentes de maquinaria ligera

Núcleo de panal de acero La tecnología juega un papel fundamental en la reducción del peso de la maquinaria industrial sin sacrificar la resistencia. La estructura única del núcleo de panal le permite proporcionar una capacidad de carga superior, a la vez que reduce significativamente el peso total de los componentes de la maquinaria. Esta reducción de peso es crucial en industrias como la aeroespacial, la automotriz y la fabricación de maquinaria pesada, donde el rendimiento y el ahorro de combustible son factores clave.

- Alta relación resistencia-peso:Una de las ventajas más significativas de núcleo de panal de aceroSu excepcional relación resistencia-peso permite la creación de componentes ligeros pero de gran durabilidad, lo que los hace ideales para equipos utilizados en aplicaciones exigentes.

- Mayor eficiencia:Al reducir el peso de los componentes de la maquinaria, núcleos de panal de aceroContribuyen a la eficiencia general del equipo. Los componentes más ligeros requieren menos energía para su movimiento, lo que se traduce en una mayor eficiencia de combustible y menores costos operativos.

Chapa de nido de abeja para aplicaciones industriales

Chapa de metal en forma de panal is commonly used in the manufacturing of industrial equipment due to its versatile properties. The combination of lightweight metal sheets and the honeycomb structure results in an ideal material for creating robust machinery components. Whether it’s used for protective casing or internal structural support, chapa metálica en forma de panal ofrece una solución eficiente para industrias que necesitan materiales de alto rendimiento.

- Durabilidad y resistencia:El uso de chapa metálica en forma de panalEn aplicaciones industriales, garantiza que los componentes sean duraderos y ligeros. Este material está diseñado para soportar un uso intensivo, manteniendo su integridad estructural a lo largo del tiempo.

- Fabricación rentable: Chapa de metal en forma de panalProporciona una solución rentable para crear componentes ligeros de maquinaria sin sacrificar la calidad. Su eficiencia productiva ayuda a reducir los costos asociados con las materias primas, el consumo energético y el tiempo de fabricación.

Panel de nido de abeja metálico para integridad estructural

En el mundo de la maquinaria industrial, la integridad estructural es esencial. Paneles de nido de abeja metálicos Se utilizan cada vez más por su capacidad para proporcionar una estructura central estable y resistente sin añadir peso excesivo. Estos paneles se emplean a menudo en la construcción de piezas de maquinaria que requieren alta resistencia y bajo peso, lo que los hace ideales para maquinaria pesada, equipos de transporte y herramientas industriales.

- Rendimiento estructural mejorado: Paneles de nido de abeja metálicosEstán diseñados para ofrecer el máximo rendimiento estructural con un mínimo de material. Su diseño único les permite absorber fuerzas y distribuir las cargas eficazmente, lo que proporciona mayor durabilidad a los componentes de la maquinaria.

- Aplicaciones versátiles:Desde fuselajes de aeronaves hasta equipos de construcción, paneles metálicos de nido de abejaSon versátiles y se pueden adaptar a una amplia gama de necesidades industriales. Su adaptabilidad los convierte en un material valioso para diversos componentes de maquinaria en diversas industrias.

Lámina de acero tipo panal para equipos de alto rendimiento

Láminas de acero en forma de panal Se utilizan ampliamente en industrias donde la reducción de peso y la alta resistencia son factores críticos. La flexibilidad de láminas de acero en forma de panal Permite su aplicación en numerosos componentes de maquinaria, desde carcasas protectoras exteriores hasta soportes estructurales internos. Estas láminas contribuyen significativamente a la reducción del peso del equipo, manteniendo al mismo tiempo los más altos estándares de seguridad y durabilidad.

- Ligero pero fuerte: Láminas de acero en forma de panalProporcionan el equilibrio ideal entre resistencia y peso. Su construcción única permite un rendimiento óptimo en maquinaria pesada, como vehículos de construcción y equipos de fabricación.

- Eficiencia energética:El uso de láminas de acero en forma de panalEl uso de maquinaria contribuye a mejorar la eficiencia energética al reducir el peso total del equipo. Una maquinaria más ligera requiere menos energía para funcionar, lo que se traduce en menores costos operativos y una menor huella ambiental.

Núcleo de panal de acero: una innovación para los equipos industriales

La integración de núcleo de panal de acero Los materiales en equipos industriales han transformado el panorama de la fabricación. Al ofrecer una reducción de peso superior sin sacrificar resistencia ni durabilidad, estos materiales se han vuelto esenciales en el diseño y la construcción de maquinaria moderna. Ya sea que se utilicen en paneles metálicos de nido de abeja para soporte estructural o chapa metálica en forma de panal Para carcasas ligeras, los beneficios de los materiales de panal de acero son claros.

- Durabilidad a largo plazo: Núcleos de panal de aceroProporcionan una larga durabilidad, garantizando que los componentes de la maquinaria se mantengan funcionales y eficaces durante años. Esta longevidad reduce los costos de mantenimiento y mejora la confiabilidad de los equipos industriales.

- Diseño ecológico:El uso de núcleo de panal de aceroLos materiales no solo mejoran la eficiencia de la maquinaria, sino que también contribuyen a un enfoque de fabricación más sostenible. Al reducir el peso de la maquinaria y mejorar la eficiencia energética, estos materiales ayudan a reducir la huella de carbono de las operaciones industriales.

Incorporando núcleo de panal de acero, paneles metálicos de nido de abeja, y chapa metálica en forma de panal El diseño de equipos industriales ofrece numerosas ventajas, como la reducción de peso, la rentabilidad y una mayor integridad estructural. Estos materiales ayudan a las industrias a alcanzar sus objetivos de rendimiento y, al mismo tiempo, a reducir su impacto ambiental. Descubra cómo láminas de acero en forma de panal y los materiales relacionados pueden optimizar los diseños de su maquinaria hoy e impulsar la innovación futura en sus operaciones industriales.

Categorías de productos

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNoticiasJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNoticiasJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNoticiasJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNoticiasJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNoticiasJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNoticiasJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNoticiasJul.11,2025