- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Durable Steel Honeycomb Core: Lightweight & High-Strength Panels

Understanding the Resurgence of Steel Honeycomb Core Technology in Industrial Applications

The demand for lightweight, high-strength, and corrosion-resistant materials continues to drive innovation across diverse industrial sectors. Among the most promising solutions, the steel honeycomb core stands out due to its exceptional strength-to-weight ratio and versatile performance characteristics. This advanced material, often integrated into sandwich structures with face sheets, delivers superior rigidity, impact resistance, and thermal insulation properties compared to traditional solid materials. Its unique cellular architecture provides an optimal balance of material usage and structural integrity, making it an ideal choice for applications where both performance and efficiency are paramount. This section delves into the fundamental aspects of steel honeycomb technology, setting the stage for a comprehensive exploration of its manufacturing, applications, and strategic advantages in today's demanding industrial landscape.

The increasing complexity of modern engineering challenges, from stringent environmental regulations in wastewater treatment to the critical need for robust yet lightweight components in aerospace, necessitates materials that can withstand extreme conditions while contributing to overall system efficiency. The strategic application of steel honeycomb core technology is experiencing a significant upward trend, particularly in specialized fields like petrochemical processing, naval architecture, and large-scale infrastructure projects. Its inherent resistance to various forms of degradation, coupled with its structural prowess, positions it as a cornerstone material for future-proof designs. Understanding the nuances of its composition and fabrication is crucial for engineers and decision-makers seeking optimal material solutions.

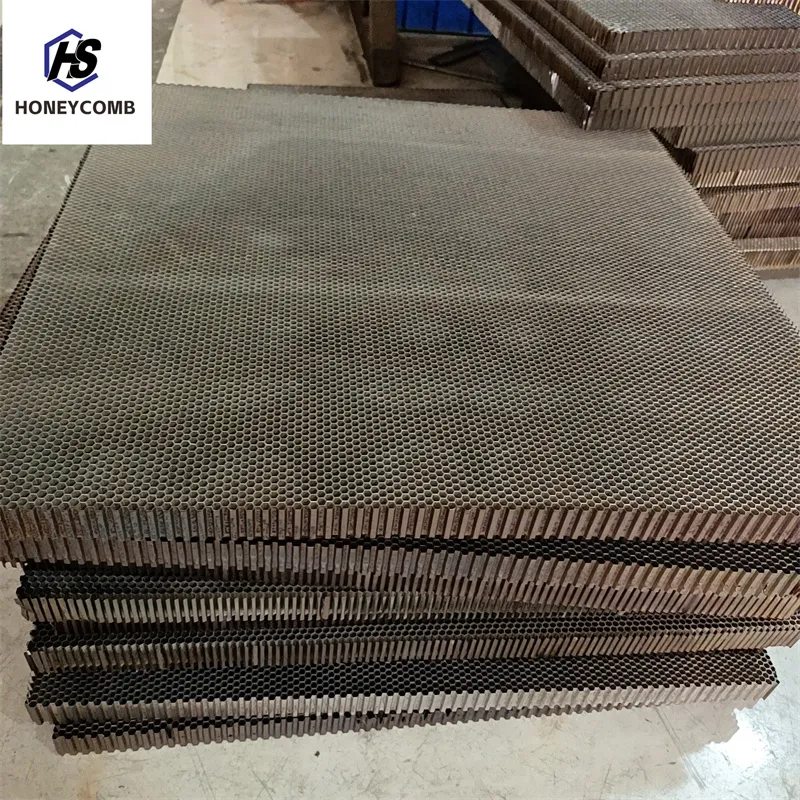

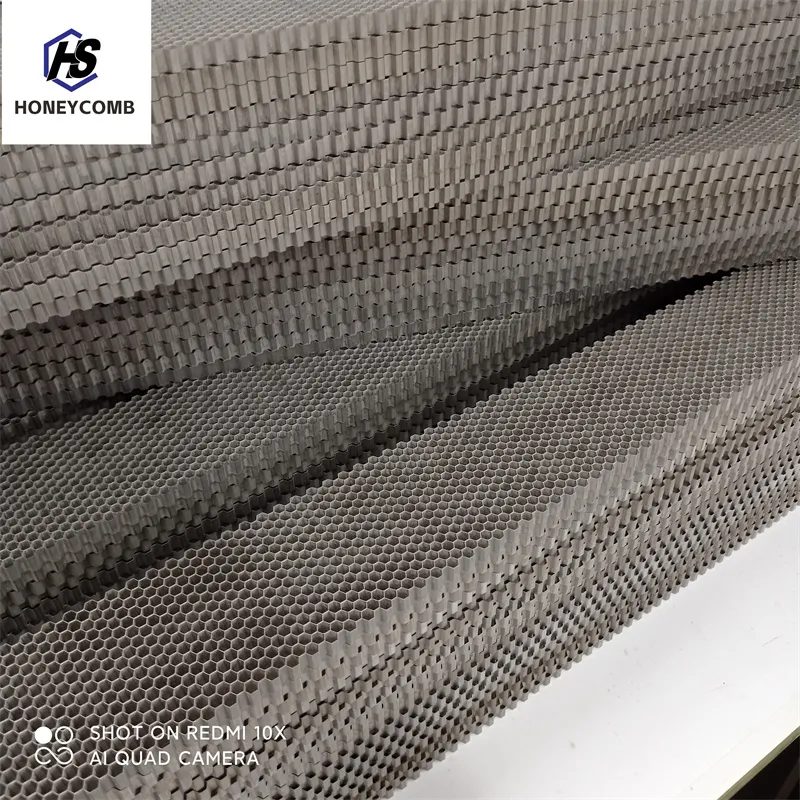

Precision Manufacturing of Steel Honeycomb Core: A Detailed Process Overview

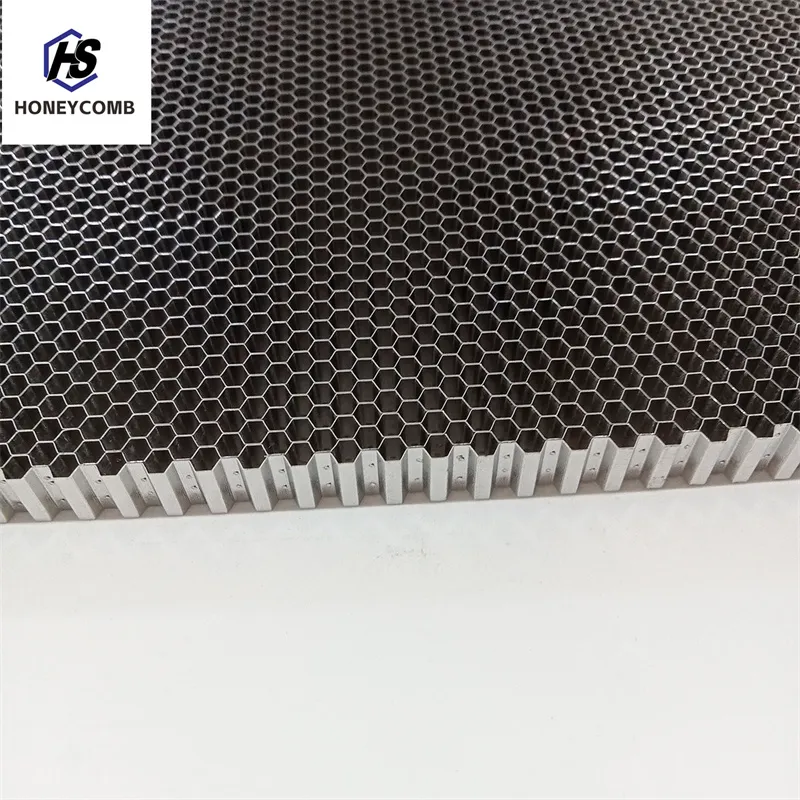

The creation of a high-quality steel honeycomb core is a meticulous process involving advanced manufacturing techniques to ensure structural integrity and consistent performance. Typically, the primary material used is stainless steel, with grades like 316 and 304 being common due to their superior corrosion resistance and mechanical properties. The manufacturing begins with high-precision steel foil sheets. These foils are then subjected to a series of sophisticated operations, including corrugation, where the sheets are shaped into wave-like patterns, and subsequent stacking and bonding. The bonding process is critical, often employing techniques such as resistance welding, diffusion bonding, or brazing to create a robust, hexagonal cellular structure. This precise arrangement is fundamental to the core's ability to distribute loads evenly and provide high compressive strength.

Post-bonding, the blocks of steel honeycomb core are typically expanded and then cut to specified dimensions using advanced CNC machining to achieve exact tolerances. Quality control is integrated at every stage. For instance, material traceability is maintained from raw material sourcing, often adhering to ASTM standards for stainless steel composition. During production, visual inspections and dimensional checks are routine. The final product undergoes rigorous testing for mechanical properties such as crush strength, shear strength, and core density, with compliance to international standards like ISO 9001:2015 being paramount. This stringent process ensures that each steel honeycomb core delivers a predicted lifespan and optimal performance in demanding industrial environments, from petrochemical processing and metallurgy to advanced water treatment facilities.

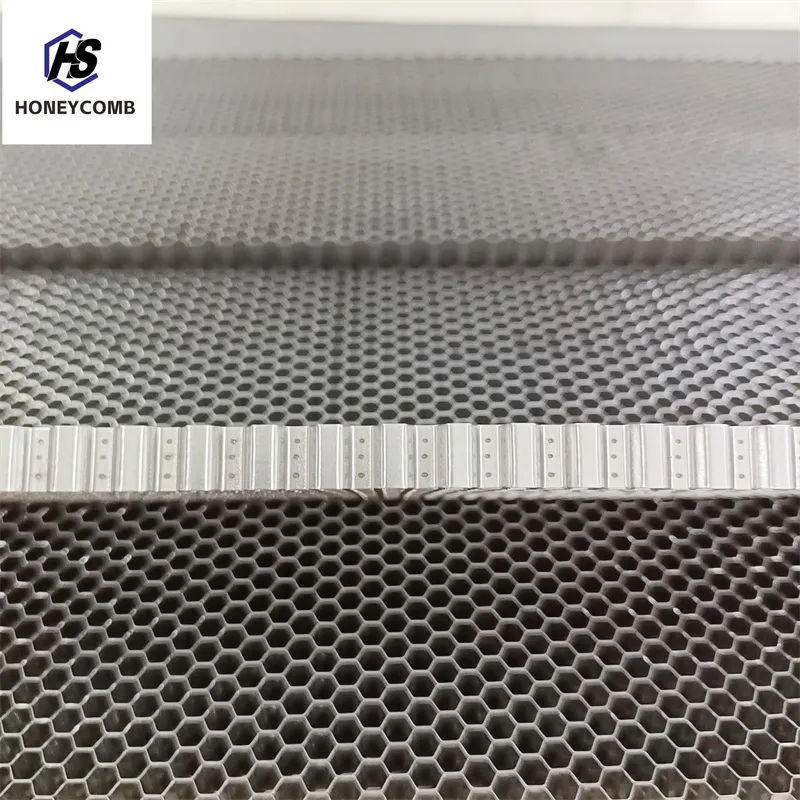

Key Technical Parameters and Performance Specifications

The performance of a steel honeycomb core is defined by a range of critical technical parameters that dictate its suitability for specific applications. These parameters include cell size, foil thickness, core thickness, and overall density. The choice of stainless steel grade, such as 316 or 304, significantly influences corrosion resistance, particularly in harsh environments like those found in sewage treatment or chemical processing. The hexagonal cellular structure itself is designed to provide isotropic mechanical properties within the plane of the core, ensuring uniform strength and stiffness.

Below is a table summarizing typical parameters for a high-performance steel honeycomb core, reflecting common industry requirements and capabilities. These values are crucial for engineers when designing lightweight structures that demand high compressive strength, shear modulus, and thermal stability.

| Parameter | Typical Value Range | Description / Benefit |

|---|---|---|

| Material Grade | 304, 316, 316L Stainless Steel | Excellent corrosion resistance, high temperature stability. 316L offers enhanced resistance to pitting and crevice corrosion. |

| Cell Size (mm) | 3.2 - 25.4 (1/8" - 1") | Determines shear strength and surface smoothness for bonding. Smaller cells yield higher strength. |

| Foil Thickness (mm) | 0.05 - 0.15 | Affects overall core density and compressive strength. Thicker foil equals higher strength. |

| Core Thickness (mm) | 6.35 - 300+ | Adjustable to meet specific structural and insulation requirements. |

| Density (kg/m³) | 48 - 320 | Low density for weight reduction, high density for increased strength. |

| Operating Temperature Range (°C) | -200 to +600 | Exceptional thermal stability for extreme environments. |

| Corrosion Resistance | Excellent (especially 316/316L) | Withstands aggressive chemical environments, vital for sewage treatment and marine applications. |

Unrivaled Advantages and Performance Benefits

The inherent properties of steel honeycomb core provide a distinct competitive edge across numerous applications. Its primary benefit lies in its exceptional strength-to-weight ratio, allowing for significant weight reduction without compromising structural integrity. This is particularly crucial in sectors like aerospace and transportation where every kilogram saved translates to fuel efficiency and increased payload capacity. Furthermore, the cellular structure offers excellent rigidity and stiffness, making it resistant to bending and crushing loads. This characteristic is invaluable in environments requiring high structural stability under dynamic stress.

Beyond structural benefits, the steel honeycomb core excels in thermal and acoustic insulation. The encapsulated air within its cells acts as an effective barrier against heat transfer, contributing to energy savings in insulated panels and industrial ovens. Similarly, its structure is highly effective at damping vibrations and absorbing sound, which is beneficial in noise-sensitive environments or for applications requiring improved acoustics. The use of stainless steel ensures outstanding corrosion resistance, making it suitable for harsh chemical exposures, marine environments, and long-term outdoor applications where other materials would quickly degrade. This longevity translates directly into reduced maintenance costs and extended operational life, offering a compelling return on investment for B2B stakeholders.

Diverse Applications Across Key Industries

The versatility of steel honeycomb core enables its application across a broad spectrum of industries, each leveraging its unique properties to solve specific engineering challenges. In the wastewater treatment sector, specifically for projects like the Customized Hexagonal 316 Stainless Steel Honeycomb Core For Sewage Treatment, its corrosion resistance against aggressive chemicals and biological agents is critical for long-term durability of media supports and structured packing. The open cellular design also facilitates efficient gas-liquid contact, crucial for biological treatment processes, enabling significant improvements in system efficiency and reduced energy consumption.

Beyond environmental engineering, steel honeycomb core finds extensive use in aerospace and defense for structural components such as aircraft wings, fuselage panels, and missile fins, where lightweight and high stiffness are paramount. In maritime applications, it's utilized for bulkheads, decks, and interior panels of ships, contributing to weight savings and enhanced fire resistance. The construction industry benefits from honeycomb core steel door construction, offering superior security, fire ratings, and sound insulation compared to traditional doors. Furthermore, in industrial furnaces and catalytic converters, the high-temperature resistance and large surface area of steel honeycomb sheets make them ideal for heat exchange and catalytic support structures, optimizing process efficiency and reducing emissions.

Customization Solutions and Industry Trends

Recognizing that standard products rarely fit every unique application, manufacturers of steel honeycomb core offer extensive customization options. This includes varying cell sizes, foil thicknesses, and core depths to meet precise load-bearing, thermal, or flow-through requirements. Custom shapes, cut-outs, and bonding patterns can also be achieved through advanced CNC capabilities. For instance, in a specific sewage treatment application, a hexagonal 316 stainless steel honeycomb core might be tailored for specific flow dynamics and corrosive resistance needs, directly impacting the longevity and efficiency of the treatment plant. This level of customization ensures optimal performance and seamless integration into complex systems, driving value for clients.

Current industry trends for steel honeycomb core point towards greater emphasis on sustainability, advanced material grades, and integrated solutions. There's a growing demand for thinner foils and larger panels to reduce overall weight and material usage, while maintaining or improving mechanical properties. Innovation in bonding technologies is leading to stronger, more reliable structures capable of performing in increasingly extreme conditions. Furthermore, the integration of smart materials and sensors within honeycomb structures is an emerging trend, enabling real-time monitoring of structural health and performance, particularly vital for critical infrastructure and high-value assets. This continuous evolution underscores the material's long-term relevance and adaptability.

Manufacturer Comparison and Strategic Selection

Selecting the right manufacturer for steel honeycomb core is a critical decision that impacts project success, quality, and cost-effectiveness. Key factors to consider include the manufacturer's experience, their range of material grades, customization capabilities, adherence to international quality standards (like ISO and ANSI), and their post-sales support. While some manufacturers may offer lower initial costs, this often comes at the expense of material quality, precise manufacturing tolerances, or insufficient testing, potentially leading to premature failure and higher long-term expenses. Reputable suppliers, like HSHI Honeycomb, prioritize precision, material traceability, and comprehensive quality assurance, ensuring optimal product longevity and performance.

A comparative analysis often reveals significant differences in lead times, pricing models, and the depth of technical support. Experienced manufacturers typically have optimized production lines and robust supply chains, allowing for more predictable delivery schedules, even for customized orders. Furthermore, their expertise extends to providing valuable engineering insights and collaborative design services. Below is a comparative table highlighting key aspects for evaluation when choosing a steel honeycomb core supplier:

| Evaluation Factor | High-Quality Manufacturer Attributes | Potential Risks with Lower-Tier Suppliers |

|---|---|---|

| Quality Certifications | ISO 9001, ASTM, traceable material origins. | Lack of verifiable certifications, inconsistent material properties. |

| Customization Capability | Full range of cell sizes, thicknesses, custom shapes, CNC processing. | Limited standard sizes, reluctance for complex custom orders. |

| Technical Support | Dedicated engineering team, design consultation, post-sales assistance. | Minimal or no technical guidance, difficult communication for issues. |

| Lead Time & Delivery | Transparent, reliable schedules; ability to handle urgent orders. | Frequent delays, inconsistent delivery, poor communication on status. |

| Pricing Model | Competitive but reflects quality, transparent cost breakdown. | Unusually low prices often indicate compromised quality or service. |

Real-World Application Cases and Success Stories

The proven performance of steel honeycomb core is best illustrated through its successful implementation in various demanding projects. For instance, in a large-scale industrial wastewater treatment plant in Southeast Asia, custom-designed hexagonal 316 stainless steel honeycomb cores were deployed as structured media. Our client reported a significant 15% increase in biological oxygen demand (BOD) removal efficiency and a 10% reduction in energy consumption for aeration, directly attributing these improvements to the optimized surface area and flow characteristics provided by the honeycomb structure. This demonstrates the tangible benefits of using tailored solutions for critical infrastructure.

Another compelling case involves a major naval shipbuilding project where steel honeycomb core panels were utilized for deck plating and bulkheads. The adoption of these lightweight panels resulted in a 7% reduction in overall vessel weight, leading to improved fuel economy and increased operational range. Furthermore, the enhanced fire resistance properties of the honeycomb panels provided an additional layer of safety compliance, exceeding international maritime regulations. In the automotive industry, specialized steel honeycomb sheets are being tested as lightweight energy absorbers in crash structures, showcasing their superior impact absorption capabilities, contributing to improved passenger safety. These diverse applications underscore the adaptability and superior performance characteristics of steel honeycomb technology across various sectors.

Ensuring Trust and Reliability: FAQs, Delivery, and Warranty

Frequently Asked Questions (FAQs)

- What are the typical lead times for a customized steel honeycomb core order?

Lead times vary depending on the complexity and volume of the order. For standard products, it can be 2-4 weeks, while complex customized hexagonal 316 stainless steel honeycomb core solutions may require 6-10 weeks. We provide a detailed project timeline upon order confirmation. - How do you ensure the quality of your steel honeycomb core products?

Our manufacturing process adheres to strict ISO 9001:2015 quality management standards. We conduct rigorous inspections at every stage, from raw material verification (conforming to ASTM/ANSI standards) to final product testing for mechanical properties (e.g., crush strength, shear strength). All products come with material test certificates (MTCs). - Can your steel honeycomb core withstand extreme temperatures?

Yes, stainless steel honeycomb cores, especially those made from 304 or 316 alloys, are designed to operate effectively across a wide temperature range, typically from -200°C to +600°C, making them suitable for high-temperature industrial applications like heat exchangers and furnaces. - What kind of after-sales support do you provide?

We offer comprehensive after-sales support including technical consultation for installation, troubleshooting assistance, and expert advice on product maintenance. Our team is dedicated to ensuring the long-term success of your application.

Delivery and Lead Time Explanation

We understand the importance of timely delivery for industrial projects. Our streamlined production process and robust logistics network ensure efficient fulfillment of orders. Standard steel honeycomb core products are typically dispatched within 15-20 business days of order confirmation. For custom solutions, particularly those requiring intricate designs or specialized material grades like the Customized Hexagonal 316 Stainless Steel Honeycomb Core, lead times are communicated transparently during the quotation phase, generally ranging from 30 to 60 business days. We maintain proactive communication throughout the manufacturing and shipping process, providing clients with regular updates and tracking information.

Quality Assurance and Warranty Commitment

Our commitment to quality is unwavering. Each steel honeycomb core product is manufactured under stringent quality control protocols, verified by ISO 9001:2015 certification. We stand behind the durability and performance of our products with a standard 12-month warranty against manufacturing defects from the date of delivery. This warranty covers material and workmanship, providing our clients with peace of mind and confidence in their investment. Our dedicated customer support team is always available to address any concerns or provide assistance, reinforcing our pledge to long-term client satisfaction and partnership.

References

- Gibson, L. J., & Ashby, M. F. (1999). Cellular Solids: Structure and Properties. Cambridge University Press.

- Wang, J., & Wen, G. (2018). Honeycomb Structures: Analysis and Design. Springer.

- ASTM International Standards for Stainless Steel and Mechanical Testing.

- ISO 9001:2015 Quality Management Systems – Requirements.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025