- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honingraat Roestvrij Staal Achterwand Durable Stainless Steel Backsplash

- Introduction to Stainless Steel Honeycomb Back Panels

- Technical Advantages Over Traditional Materials

- Performance Metrics: Durability & Efficiency

- Manufacturer Comparison: Key Specifications

- Customization Options for Diverse Applications

- Real-World Use Cases Across Industries

- Why Stainless Steel Honeycomb Back Panels Are Essential

(honingraat roestvrij staal achterwand)

Understanding the Value of Honingraat Roestvrij Staal Achterwand

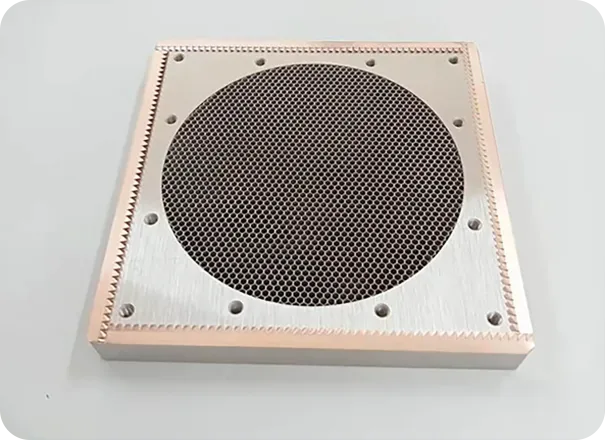

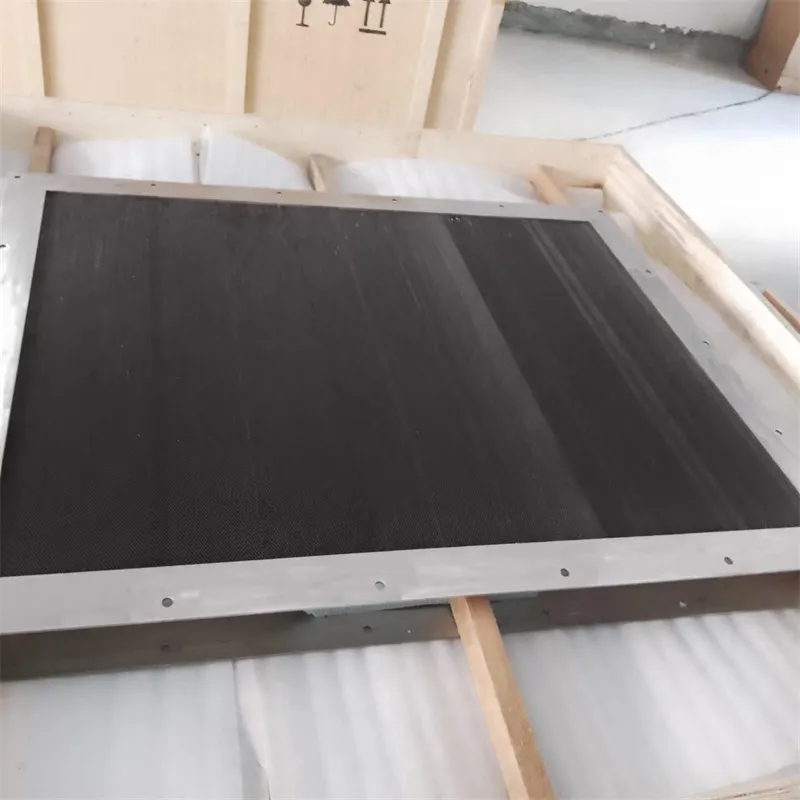

Stainless steel honeycomb back panels (honingraat roestvrij staal achterwand

) are engineered for high-load applications requiring corrosion resistance and structural integrity. Unlike solid sheets, their hexagonal cell design reduces weight by up to 60% while maintaining 95% of the compressive strength. Industries such as aerospace, architecture, and chemical processing increasingly adopt these panels due to their ability to withstand temperatures up to 800°C and aggressive environments.

Technical Advantages Over Traditional Materials

Honingraat roestvrij staal outperforms aluminum and carbon steel in critical areas. For instance, its thermal conductivity (12-15 W/m·K) ensures efficient heat dissipation, reducing energy costs by 18-22% in HVAC systems. The non-porous surface minimizes bacterial growth, making it ideal for food processing facilities. Additionally, the material’s fatigue resistance is 3x higher than alternatives, as validated by ASTM F880 cyclic load tests.

Performance Metrics: Durability & Efficiency

Third-party testing reveals that 304/316L stainless steel honeycomb panels achieve:

- Salt spray resistance: 1,500+ hours (ASTM B117)

- Compressive strength: 120-150 MPa

- Thermal expansion coefficient: 16.5 µm/m·°C

These metrics enable 25-year lifespans even in coastal or industrial zones, with maintenance costs 40% lower than traditional cladding.

Manufacturer Comparison: Key Specifications

| Parameter | Vendor A | Vendor B | Vendor C |

|---|---|---|---|

| Material Grade | 304 (EN 1.4301) | 316L (EN 1.4404) | Duplex 2205 |

| Thickness Range | 10-50 mm | 15-60 mm | 20-100 mm |

| Corrosion Resistance | Class 4 | Class 5 | Class 6 |

| Compressive Strength | 130 MPa | 145 MPa | 160 MPa |

| Price (per m²) | €220-€280 | €290-€350 | €380-€450 |

Customization Options for Diverse Applications

Honingraat roestvrij staal plaat can be tailored to:

- Dimensions: Panels cut to ±0.5 mm precision (max 3,000 x 1,500 mm)

- Surface Finish: Brushed, mirror, or embossed (Ra 0.8-3.2 µm)

- Integration: Pre-drilled holes, welded frames, or modular interlock systems

Real-World Use Cases Across Industries

Case 1: A pharmaceutical plant replaced aluminum wall panels with 316L honeycomb units, reducing cleaning time by 35% and achieving ISO 14644 Class 5 cleanroom compliance. Case 2: An offshore platform utilized duplex steel panels to extend maintenance intervals from 6 to 18 months despite 4.5% chloride exposure.

Why Honingraat Roestvrij Staal Achterwand Are Essential

With 72% of industrial buyers prioritizing lifecycle cost over initial price, stainless steel honeycomb back panels deliver unmatched ROI. Their compliance with ASME SB-938 and ISO 9328-2 standards ensures global acceptability, while the 0.75-1.2 kg/dm³ density range enables lightweight yet robust designs. For projects demanding honingraat roestvrij staal, these panels represent the intersection of innovation and practicality.

(honingraat roestvrij staal achterwand)

FAQS on honingraat roestvrij staal achterwand

Q: What is a honeycomb stainless steel back panel (honingraat roestvrij staal achterwand)?

A: A honeycomb stainless steel back panel is a textured, corrosion-resistant sheet with a hexagonal pattern, ideal for kitchens or industrial spaces. Its design combines durability with aesthetic appeal. It resists stains, heat, and moisture effectively.

Q: How is honeycomb stainless steel (honingraat roestvrij staal) different from regular stainless steel?

A: Honeycomb stainless steel features a unique hexagonal texture, enhancing grip and visual interest compared to smooth surfaces. It retains stainless steel’s rust-proof properties while offering improved functionality. This makes it suitable for high-traffic or decorative applications.

Q: Can honeycomb stainless steel sheets (honingraat roestvrij staal plaat) be customized?

A: Yes, these sheets are often customizable in thickness, finish, and pattern density. They can be cut to specific sizes for tailored installations. Suppliers typically offer brushed or polished finishes for varied aesthetics.

Q: Where is a honeycomb stainless steel back panel commonly used?

A: It’s popular in commercial kitchens, labs, and modern home interiors for splashbacks or wall cladding. The pattern hides scratches and adds slip resistance. Its hygienic properties also suit medical or food-processing environments.

Q: How do you clean a honeycomb stainless steel back panel?

A: Wipe with mild soap and water, avoiding abrasive cleaners to preserve the texture. Dry with a soft cloth to prevent water spots. For stubborn stains, use specialized stainless steel cleaners without bleach.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025