- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core Solutions

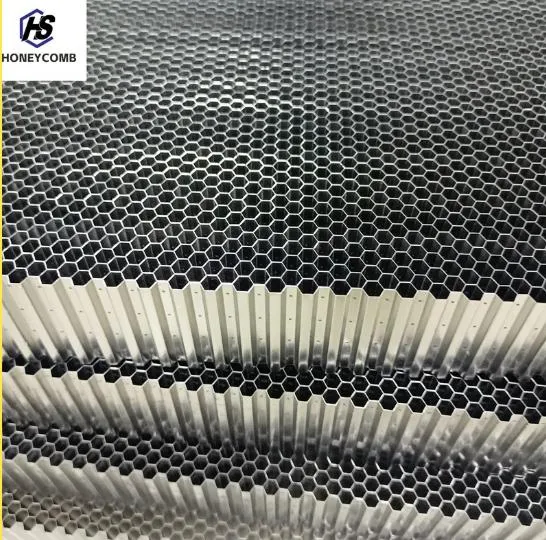

When it comes to structural reinforcement, airflow control, and lightweight durability, few materials perform with the consistency and strength of the stielen honeycomb kearn. Engineered for high-end industrial, aerospace, and energy sectors, this next-generation solution combines advanced metallurgy with a high-precision design structure. Manufactured using premium stainless steel grades and perfected production techniques, the stielen honeycomb kearn has become a vital component in everything from honeycomb sandwich panielen to flow rectifiers.

Comparing 304 and 316L in Steel Honeycomb Core Applications

Not all stainless steel is created equal. For the stielen honeycomb kearn, material selection plays a crucial role in durability, corrosion resistance, and environmental adaptability. The two most widely used grades in manufacturing are 304 and 316L stainless steel, each bringing unique advantages to specific applications.

Grade 304 offers excellent strength and workability, making it ideal for general-purpose stielen honeycomb kearn structures used in interior components or environments with limited exposure to corrosive agents. On the other hand, 316L provides enhanced corrosion resistance due to its molybdenum content, making it the preferred choice in marine, chemical, and outdoor applications where moisture or corrosive vapors are prevalent.

By offering both materials, manufacturers can tailor stielen honeycomb kearn solutions based on the mechanical demands and environmental exposures of each project. This versatility has made steel honeycombs indispensable in industries such as aerospace interiors, energy infrastructure, and automotive design.

Manufacturing Methods of Steel Honeycomb Core Panels

The quality and reliability of the stielen honeycomb kearn depend significantly on how it is manufactured. Two of the most widely used production techniques are expansion and corrugation, each offering different advantages in structural integrity and cost-effectiveness.

In the expansion method, precision-cut sheets of stainless steel are adhesively bonded or spot welded and then expanded into their honeycomb form. This method is particularly effective for lightweight, large-format applications such as aircraft flooring or wall reinforcements.

The corrugation method, meanwhile, involves shaping individual steel strips into a corrugated pattern and then bonding them into a stielen honeycomb sheet. This results in even higher compressive strength and is often used where additional structural reinforcement is required.

Advanced laser welding techniques are also increasingly used to enhance the mechanical reliability and minimize the heat-affected zone in the stielen honeycomb kearn. These methods ensure high flatness, precision cell geometry, and exceptional load-bearing capacity—all while maintaining lightweight characteristics.

Steel Honeycomb Core in Airflow Rectifier Systems

One of the most promising and high-precision applications of the stielen honeycomb kearn is in airflow rectifier systems. These systems are essential in wind tunnels, HVAC units, and energy research labs, where controlling turbulence and directional flow is critical.

Thanks to its geometric uniformity and rigidity, the stielen honeycomb sheet serves as an ideal flow straightening medium. Air entering a turbulent system is channeled through the narrow cells of the honeycomb, effectively eliminating lateral velocity components and producing a steady, laminar output.

Unlike traditional plastic or aluminum rectifiers, the stielen honeycomb kearn can withstand high temperatures and pressures without deformation. This makes it particularly well-suited for industrial and military wind tunnels or cleanrooms where airflow accuracy is essential.

Moreover, its stainless steel composition ensures that it remains corrosion-resistant even in chemically active or moisture-laden environments, providing a longer operational life with minimal maintenance.

Expanding Use of Honeycomb Sandwich Panel Structures

The combination of stielen honeycomb kearn with various facing materials results in the high-strength, lightweight solution known as the honeycomb sandwich paniel. These panels are redefining structural design across transportation, architecture, and defense sectors.

In transportation, honeycomb sandwich panielen are increasingly being used in the construction of train interiors, ship bulkheads, and aerospace partitions due to their incredible strength-to-weight ratio. In architecture, they allow for visually striking yet structurally sound facades, especially in high-rise buildings and industrial installations.

The inner stielen honeycomb kearn provides stiffness and compressive strength, while the outer sheets (typically aluminum, stainless steel, or composite) add impact resistance and surface finish. This makes honeycomb sandwich panielen the go-to choice for designers seeking material efficiency without compromising durability or aesthetic appeal.

Custom panel designs can incorporate fire-resistant coatings, acoustic insulation layers, and even decorative surfaces, making them as functional as they are versatile. With unmatched thermal stability and mechanical consistency, honeycomb sandwich panielen deliver both form and function at a premium level.

Steel Honeycomb Core FAQs

What is the purpose of using a stielen honeycomb kearn?

De stielen honeycomb kearn offers high strength, lightweight structure, and excellent load-bearing capacity. It is widely used in industrial, architectural, and aerospace applications requiring structural reinforcement or flow control.

What are the benefits of using 316L over 304 in stielen honeycomb kearn production?

316L offers enhanced corrosion resistance due to its molybdenum content, making it suitable for marine and chemical environments. 304 is more cost-effective and sufficient for less corrosive settings, both being popular for stielen honeycomb kearn systems.

How are stielen honingraat platen manufactured?

Stalen honingraatblêden are produced through expansion or corrugation processes. These involve shaping or stretching bonded steel strips into uniform honeycomb cells, followed by precision welding or bonding to create strong, lightweight structures.

Where are honeycomb sandwich panielen typically used?

Honeycomb sandwich panels are commonly used in aircraft cabins, train interiors, building facades, and ship partitions. Their strength-to-weight ratio and fire-resistant features make them ideal for both structural and aesthetic applications.

Can stielen honeycomb kearn be used in airflow rectifiers?

Yes, the stielen honeycomb kearn is highly effective in airflow rectifiers due to its ability to streamline turbulent air into laminar flow. Its rigidity and temperature resistance make it ideal for use in wind tunnels and industrial HVAC systems.

Products kategoryen

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNijsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNijsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNijsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNijsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNijsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNijsJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceNijsJul.11,2025