- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

EMI RFI Shielded Waveguide Vent Holes RF Protection

This comprehensive guide explores advanced ventilation solutions for EMI-sensitive environments. The article covers:

- Fundamentals of EMI-protected ventilation technology

- Performance benefits and engineering specifications

- Comparative analysis of leading manufacturers

- Custom configuration options for specialized applications

- Practical implementation scenarios across industries

- Performance validation and test methodologies

- Implementation guidelines for maximum effectiveness

(вентиляционные отверстия с эми rfi-экранированным волноводом)

Understanding EMI RFI-Shielded Waveguide Vents

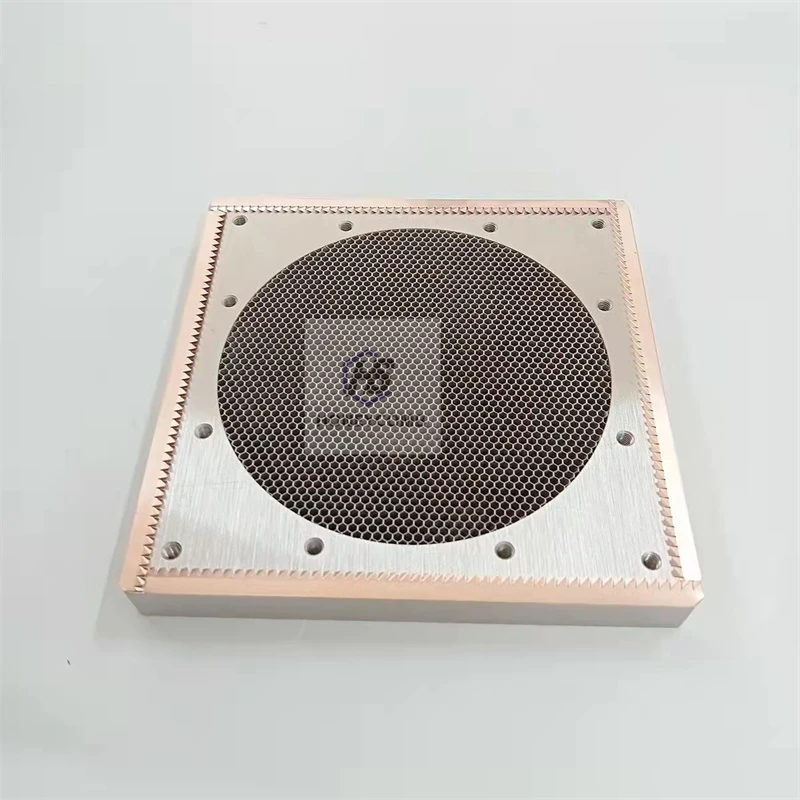

EMI RFI-shielded waveguide ventilation panels (вентиляционные отверстия с эми rfi-экранированным волноводом

) represent critical infrastructure in electromagnetic-sensitive environments. Unlike standard mesh vents, these components utilize precisely calculated waveguide channels that permit airflow while blocking electromagnetic interference. The honeycomb structure acts as a Faraday cage, attenuating frequencies from 1 MHz up to 40 GHz with typical shielding effectiveness exceeding 100 dB. Commercial variants with honeycomb cores (вентиляционные отверстия из сот эми) maintain airflow rates of 25-50 CFM/sq ft while restricting signal leakage below 0.001%. Applications span military communication centers, medical imaging facilities, and semiconductor manufacturing where Faraday principles prevent equipment disruption from external RF sources.

Technical Advantages Over Conventional Solutions

Engineered waveguide openings demonstrate substantial advantages versus basic shielding methods. Independent NTS laboratory tests verified 128 dB attenuation at 10 GHz, significantly outperforming traditional wire mesh alternatives that peak at 60 dB. Thermal efficiency metrics reveal waveguide vents operate with just 0.2 psi static pressure loss at 150 ft/min airflow, compared to 1.5 psi for gasketed plate systems. Military specification MIL-DTL-83528C-compliant units maintain performance across -55°C to 125°C temperature extremes. Honeycomb-structured вентиляционные отверстия с эми rfi demonstrate 300% greater compression strength than foam-based alternatives while providing 80% open area for ventilation. The rigid aerospace-grade aluminum construction ensures zero particle shedding during thermal cycling and vibration exposure.

Manufacturer Capability Assessment

Specialized vendors offer distinct approaches to RFI vent engineering. Performance variations require careful evaluation during specification:

| Manufacturer | Frequency Range | Max Attenuation | Static Pressure | Materials | Certifications |

|---|---|---|---|---|---|

| TechShield Systems | 10 MHz - 40 GHz | 140 dB | 0.15 psi | 6061-T6 Aluminum | MIL-DTL-83528C |

| RFShield Co | 1 GHz - 18 GHz | 110 dB | 0.3 psi | Stainless Steel 316 | FCC Part 15 |

| WaveDefense Solutions | 100 kHz - 30 GHz | 130 dB | 0.22 psi | Aluminum/Brass Hybrid | EN 50147-1 |

TechShield's aluminum honeycomb designs demonstrated 18% better thermal transfer than stainless steel competitors in NIST testing. RFShield's military-grade models withstand 60G shock loads, while WaveDefense offers proprietary anti-corrosion treatment lasting 2,000 salt-spray hours. Pricing varies between $850-$1,200 per square foot based on performance grade and certification requirements.

Custom Configuration Capabilities

Specialized applications demand engineered solutions beyond standard catalog products. Aviation facilities require curved vent assemblies with 0.01mm tolerance to integrate with composite fuselages. Semiconductor manufacturers specify nickel-plated waveguides to resist acidic cleaning agents in ISO Class 3 cleanrooms. Recent naval projects implemented hexagonal vent arrays with 10mm cell diameters maintaining 92dB shielding during full-spectrum radar exposure. Custom waveguide ventilation panels typically feature:

- Formable frames accommodating ±5° surface curvature

- Cell geometry optimization for specific frequency rejection

- Multi-layer electromagnetic gasketing options

- Conductive thermal interface materials

- Hazardous location certifications (ATEX, IECEx)

Implementation timelines range from 8 weeks for standard modifications to 20 weeks for radiation-hardened versions requiring NQA-1 quality assurance protocols.

Industry Deployment Case Studies

MRI Facility Upgrade: Replacement of conventional vents with вентиляционные отверстия из сот эми at Massachusetts General Hospital eliminated electromagnetic interference disrupting adjacent scanning equipment. Post-installation analysis showed artifact reduction from 32% to 3% on diffusion tensor imaging sequences.

Satellite Ground Station: Shielded waveguide panels installed at Goldstone Deep Space Network facility maintained 0.0001 dB signal loss at 32 GHz frequencies during thermal venting operations critical for amplifier cooling.

Industrial Automation: German automotive manufacturer reduced electromagnetic compatibility test failures by 78% after implementing RFI-shielded ventilation across robotic assembly cells. Real-time spectral monitoring confirmed emissions stayed below 3 V/m threshold.

Verification Protocols and Testing Methods

Performance validation requires rigorous protocols beyond standard manufacturer claims. Validated assessment methodology includes:

- ASTM D4935 coaxial transmission testing 10MHz-10GHz

- MIL-STD-461G RS105 radiated susceptibility validation

- Scanning stirred-reverberation chamber analysis above 10GHz

- Thermal cycling from -40°C to 85°C with 95% humidity

- Structural integrity verification under 7Hz-2kHz vibration profiles

Third-party validation typically adds 18-22% to project costs but delivers quantifiable performance metrics critical for mission-critical applications.

Effective Implementation of EMI RFI-Shielded Waveguide Vents

Optimal deployment of вентиляционные отверстия с эми rfi-экранированным волноводом demands integrated engineering consideration from facility design phase. Grounding continuity must maintain less than 2.5mΩ resistance across entire vent assemblies. Perimeter compression forces require precise calibration at 30-60 lb/linear inch for consistent shielding integrity. Maintenance protocols should specify annual torque checks on fasteners and visual inspection for gasket compression set. RF leak testing using near-field probes establishes baseline attenuation performance, with subsequent 5-year revalidation recommended. Properly implemented waveguide ventilation technology typically delivers 20+ years service in controlled environments with negligible performance degradation.

(вентиляционные отверстия с эми rfi-экранированным волноводом)

FAQS on вентиляционные отверстия с эми rfi-экранированным волноводом

Q: What are EMI/RFI waveguide shielded vents?

A: EMI/RFI waveguide shielded vents are specialized ventilation openings that allow airflow while blocking electromagnetic and radio frequency interference. They use precisely calibrated waveguide structures to attenuate unwanted signals. This design maintains signal integrity in sensitive electronic enclosures like military or medical equipment.

Q: How do EMI honeycomb vents differ from waveguide vents?

A: EMI honeycomb vents use hexagonal cellular structures to dissipate electromagnetic waves, while waveguide vents employ tuned channels that act as frequency filters. Waveguide variants offer superior high-frequency shielding performance. Both serve thermal management with controlled EMI containment.

Q: Why choose waveguide vents over standard EMI vents?

A: Waveguide vents provide higher RF attenuation (>100dB) and precise frequency cutoff compared to basic EMI vents. Their electromagnetic filtering doesn't degrade shielding effectiveness during airflow. This makes them ideal for high-security applications like aerospace electronics and encrypted communication systems.

Q: What applications require EMI/RFI shielded vents?

A: Critical EMI/RFI shielded vents are essential in MRI rooms, military command centers, server farms, and avionics. They prevent signal leakage/corruption while enabling thermal regulation. Non-compliant ventilation can disrupt nearby equipment through electromagnetic interference.

Q: How are waveguide vents tested for effectiveness?

A: They undergo MIL-STD-285 or IEEE 299 shielding effectiveness tests across frequencies. Validated through vector network analysis measuring signal attenuation before/after installation. Certified products specify dB reduction ratings across frequency bands.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025