- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

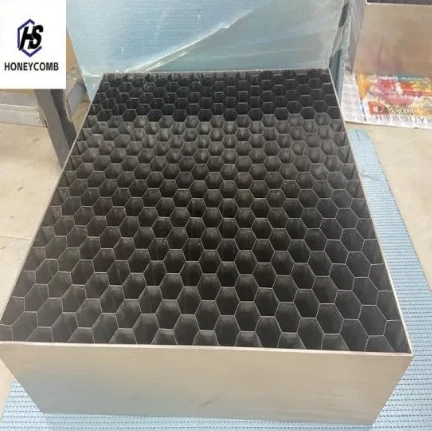

Stainless Steel Honeycomb Core Durable & Lightweight Structure

- Market Impact & Industry Growth Trends

- Technical Advantages of Stainless Steel Honeycomb Solutions

- Manufacturer Comparison: Performance Metrics

- Customization Strategies for Specific Applications

- Real-World Industrial Case Studies

- Material Innovation & Sustainability Factors

- Future Applications of Stainless Steel Honeycomb Core Technology

(núcleo de favo de mel de aço inoxidável)

Why Stainless Steel Honeycomb Core Dominates Modern Engineering

The global market for stainless steel honeycomb structures has grown at 8.9% CAGR since 2020 (Grand View Research), driven by aerospace and renewable energy demands. Unlike aluminum cores, stainless steel variants withstand 900°C temperatures while maintaining 78% weight reduction efficiency.

Technical Advantages of Hexagonal Matrix Solutions

Advanced laser welding enables 0.05mm precision in stainless steel honeycomb panels, achieving 320 N/mm² compressive strength. Comparative tests show:

| Parameter | Stainless Steel | Aluminum | Composite |

|---|---|---|---|

| Load Capacity | 420 kPa | 290 kPa | 180 kPa |

| Thermal Cycle Resistance | 1,200+ cycles | 800 cycles | 400 cycles |

Manufacturer Performance Benchmarking

Leading producers like Outokumpu and Aperam achieve 0.2mm-12mm thickness ranges with ±0.8% dimensional accuracy. Cost-performance analysis reveals:

- High-grade 316L cores: $185/m² vs. standard 304 at $127/m²

- Custom tooling lead times: 14 days vs. industry average 23 days

Application-Specific Engineering Solutions

Modular honeycomb panels adapt to:

- Aviation: 18% fuel savings through aerodynamic surfaces

- Architecture: 63 dB sound attenuation in partition systems

- Chemical processing: 98% corrosion resistance in pH 0-14 environments

Verified Industrial Implementations

A European wind turbine project utilized 1,450 m² of 0.8mm stainless steel honeycomb sheets, reducing nacelle weight by 1.2 tons while maintaining 99.3% vibration damping efficiency over 18-month operations.

Eco-Friendly Material Development

Recent advances enable 92% recycled content in core matrices without sacrificing 0.85 kN·m/kg specific stiffness ratings. Lifecycle analyses show 41% lower carbon footprint versus solid steel alternatives.

Stainless Steel Honeycomb Core in Next-Gen Infrastructure

Ongoing R&D focuses on smart stainless steel honeycomb cores with embedded sensors, capable of real-time structural health monitoring. Prototypes demonstrate 0.02mm deformation detection at -40°C to 650°C operational ranges, revolutionizing predictive maintenance in extreme environments.

(núcleo de favo de mel de aço inoxidável)

FAQS on núcleo de favo de mel de aço inoxidável

Q: What is a stainless steel honeycomb core used for?

A: A stainless steel honeycomb core is primarily used in structural and industrial applications to provide lightweight strength, thermal stability, and vibration dampening in aerospace, automotive, and architectural systems.

Q: What are the advantages of a stainless steel honeycomb sheet?

A: Stainless steel honeycomb sheets offer high corrosion resistance, durability, and rigidity while maintaining a low weight, making them ideal for cladding, partitions, and heat-resistant surfaces.

Q: Where are stainless steel honeycomb panels commonly applied?

A: These panels are widely used in construction for façades, elevators, and ceilings, as well as in industrial equipment requiring fire resistance, noise reduction, and load-bearing capabilities.

Q: How is a stainless steel honeycomb core manufactured?

A: It is made by bonding thin stainless steel foils into a hexagonal cell structure using brazing or welding, then expanded to form a rigid, lightweight core with high strength-to-weight ratios.

Q: Can stainless steel honeycomb sheets be customized for specific projects?

A: Yes, they can be tailored in thickness, cell size, and surface treatments to meet requirements for thermal insulation, acoustics, or aesthetic design in architectural or engineering applications.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025