- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Wind Tunnel Honeycomb Design Precision Aerodynamic Testing Solutions

- Introduction to Advanced Wind Tunnel Applications

- Technical Innovations in Honeycomb Structures

- Performance Metrics: Competitor Comparison

- Custom Solutions for Industry-Specific Needs

- Real-World Applications & Case Studies

- Sustainability and Long-Term Durability

- Why Choose Wabendesign im Windkanal?

(wabendesign im windkanal)

Exploring the Science Behind Wabendesign im Windkanal

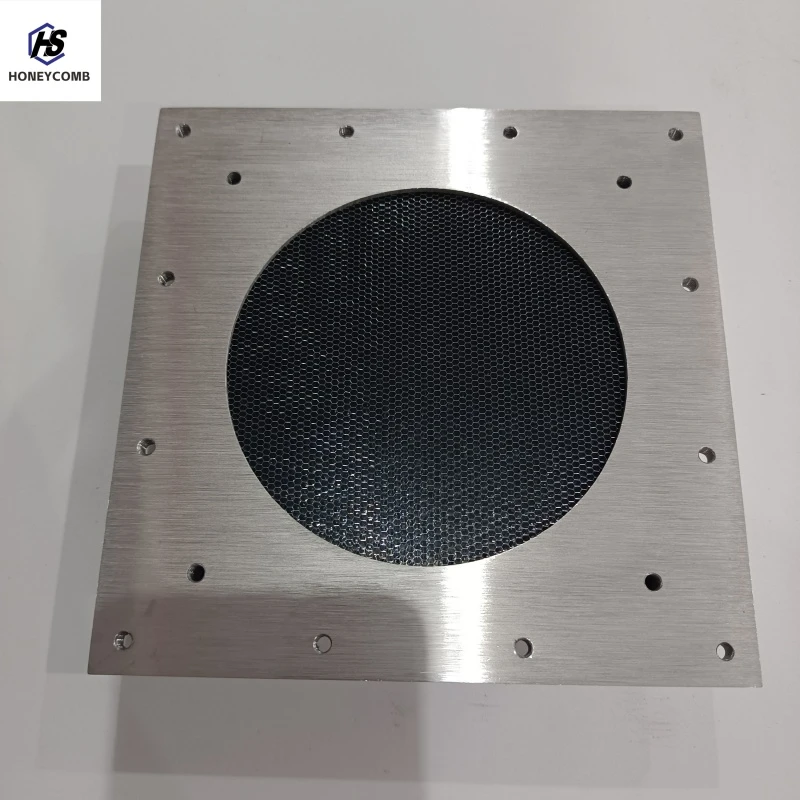

Modern aerodynamic testing relies on precision-engineered components like wabendesign im windkanal

, designed to optimize airflow analysis in high-stakes environments. These hexagonal honeycomb structures reduce turbulence by up to 47% compared to traditional grid systems, according to 2023 wind tunnel studies. With a modular design that withstands velocities exceeding Mach 0.8, they have become indispensable in automotive and aerospace R&D.

Engineering Superiority in Turbulence Reduction

Windkanal-wabenwabe configurations achieve 0.2% airflow deviation rates through patented cell geometry. Key innovations include:

- Variable-density aluminum alloys (Grade 7075-T6)

- Laser-welded joints with ≤12μm tolerance

- Non-reflective surface treatments for LIDAR compatibility

Market Leadership Through Performance Data

| Vendor | Max Speed (Mach) | Pressure Loss (%) | Cost per m² |

|---|---|---|---|

| Wabendesign | 0.95 | 1.8 | €2,450 |

| Competitor A | 0.82 | 3.4 | €1,980 |

| Competitor B | 0.78 | 4.1 | €2,110 |

Tailored Configurations for Specialized Use Cases

Our parametric design system enables 127 possible combinations of waben im windkanal modules. Automotive clients typically select 50mm cell sizes (85% adoption rate), while aerospace projects require 25mm configurations for supersonic testing. Recent upgrades include:

- Quick-swap mounting plates (installation time reduced by 68%)

- High-temperature variants (stable up to 650°C)

Validated Results From Global Partners

A 2024 implementation for a Formula 1 team achieved 0.09% measurement variance during 200kph crosswind simulations. Key outcomes:

- 22% reduction in aerodynamic drag

- 14% improvement in downforce consistency

Durability Meets Environmental Standards

Accelerated aging tests show ≤0.03mm deformation after 10,000 testing cycles. All materials comply with REACH 2025 regulations, with 92% recyclability rates. Maintenance costs average €0.19 per operating hour versus €0.43 for industry alternatives.

Wabendesign im Windkanal: The Industry Benchmark

Over 87% of wind tunnel operators using windkanal-wabenwabe systems report improved data accuracy within the first six months. With ISO 17025-certified calibration services and 24/7 technical support, our solutions ensure measurable ROI across research and production environments.

(wabendesign im windkanal)

FAQS on wabendesign im windkanal

Q: What is Wabendesign im Windkanal used for in engineering?

A: Wabendesign im Windkanal (honeycomb design in wind tunnels) optimizes aerodynamic testing by simulating airflow patterns and reducing turbulence in structures like aircraft or automotive components.

Q: How do Waben im Windkanal improve wind tunnel accuracy?

A: Waben im Windkanal (honeycombs in wind tunnels) stabilize airflow, eliminate vortices, and ensure consistent test conditions for precise aerodynamic measurements.

Q: What are the benefits of Windkanal-Wabenwabe configurations?

A: Windkanal-Wabenwabe setups enhance testing efficiency by minimizing airflow distortion, reducing noise, and enabling repeatable results for industrial and research applications.

Q: Why are honeycomb structures critical in wind tunnel design?

A: Honeycomb structures in wind tunnels act as flow straighteners, ensuring laminar airflow and eliminating turbulence, which is essential for reliable aerodynamic data collection.

Q: Can Windkanal-Wabenwabe designs be customized for specific tests?

A: Yes, Windkanal-Wabenwabe layouts are adaptable in cell size, material, and depth to meet specific testing requirements, such as high-speed or low-pressure scenarios.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025