- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Innovative Steel Honeycomb Solutions for Modern Applications

Steel honeycomb materials are at the forefront of a range of industries, offering unmatched durability, efficiency, and functionality in various applications. Whether you are in the aerospace, construction, or electronics sector, steel honeycomb sheets, dyer çeliku me bërthamë mjalti, steel honeycomb laser beds, metal honeycomb cores, ose honeycomb for EMI shielding can transform your products and solutions. These materials are vital for lightweight yet robust structural integrity, enhanced electromagnetic interference protection, and much more. Here’s an in-depth look at how these cutting-edge materials are revolutionizing industries.

What is Steel Honeycomb Sheet and Its Applications?

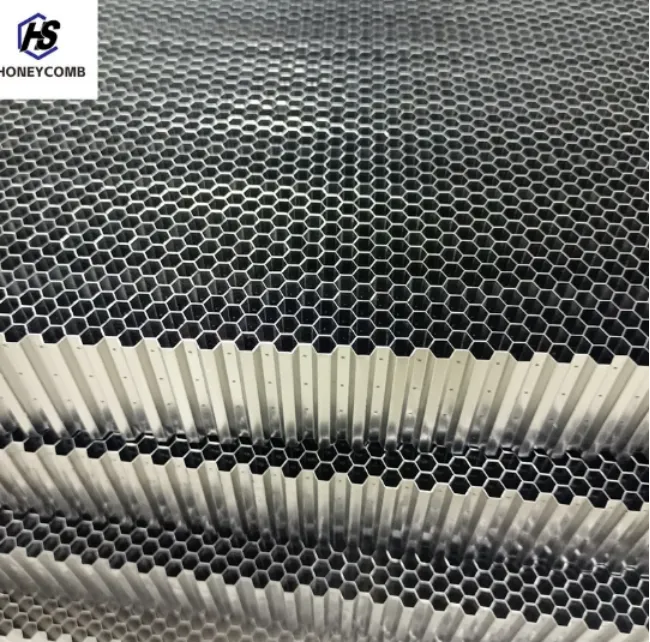

A fletë çeliku huall mjalti is a high-performance material made from a combination of thin steel layers and a honeycomb core structure. The core consists of hexagonal cells that create an exceptionally strong yet lightweight sheet. This material is known for its ability to withstand high pressures while maintaining a low weight profile, making it ideal for use in industries such as aerospace, automotive, and construction.

Të fletë çeliku huall mjalti provides excellent structural support, making it an excellent choice for aircraft, automotive bodies, and high-load-bearing applications. One of the significant benefits of using fletë çeliku huall mjalti is their high strength-to-weight ratio, meaning that they can offer maximum durability without adding unnecessary weight to structures. This makes them ideal for use in industries where both strength and weight are of critical importance.

In addition to aerospace and automotive uses, fletë çeliku huall mjalti are increasingly used in architectural projects, particularly in the construction of large buildings where weight considerations are paramount. The material's ability to resist corrosion and wear also makes it perfect for environments with harsh conditions, including offshore oil rigs and industrial settings.

The Role of Honeycomb Core Steel Doors in Security and Insulation

Dyer çeliku me bërthama mjalti are essential components in providing high levels of security and insulation for commercial and industrial applications. These doors are constructed using a steel outer shell and a honeycomb core that gives them exceptional strength and resistance to impact, making them ideal for areas requiring high levels of protection.

The use of a honeycomb core inside steel doors significantly enhances their performance. The honeycomb structure improves the door’s resistance to forced entry and provides excellent thermal and sound insulation. This makes dyer çeliku me bërthamë mjalti an optimal choice for applications such as data centers, secure government buildings, and high-security facilities. In addition to their protective qualities, these doors offer efficient soundproofing and temperature regulation, ensuring that they meet both security and environmental needs.

For industries that demand both performance and security, dyer çeliku me bërthamë mjalti are a reliable choice, offering a balance of durability, energy efficiency, and ease of maintenance. Whether in high-security environments or spaces that require noise and temperature control, these doors stand up to the challenge.

Steel Honeycomb Laser Bed: Advancing Manufacturing Efficiency

Steel honeycomb laser beds are revolutionizing the manufacturing sector by providing a stable, durable surface for laser cutting and other precision processes. These beds are designed to hold materials steady while being cut or processed with high-precision equipment, ensuring optimal results in both speed and accuracy.

Të steel honeycomb laser bed is designed to reduce weight and increase load-bearing capacity, which is essential for the precision needed in laser cutting. The honeycomb structure of these beds offers an excellent combination of rigidity and lightness, making them suitable for a variety of applications in industries such as electronics, aerospace, and metal fabrication. The design also minimizes material distortion during the laser cutting process, which increases the quality of the cut and extends the lifespan of the laser bed.

Për më tepër, steel honeycomb laser beds are resistant to wear and tear, making them ideal for high-frequency use in manufacturing environments. These beds provide stable support for delicate parts and materials, ensuring that each piece is cut with the highest level of precision. As the demand for faster and more efficient manufacturing increases, steel honeycomb laser beds offer manufacturers a competitive edge by improving their production capabilities and reducing operational costs.

Metal Honeycomb Core: The Backbone of Lightweight, High-Performance Designs

Të metal honeycomb core is one of the most versatile materials used in engineering and design today. Composed of thin metallic sheets arranged in a honeycomb pattern, the metal honeycomb core offers an ideal solution for lightweight structures that require excellent strength and durability. This material is used in a wide range of industries, from aerospace to construction and electronics, due to its impressive strength-to-weight ratio.

One of the key advantages of metal honeycomb cores is their ability to distribute load evenly across a surface, providing structural support while minimizing weight. This makes them ideal for use in aircraft fuselages, bridges, and flooring systems where both strength and lightness are necessary. In addition, metal honeycomb cores offer excellent thermal and acoustic insulation properties, making them suitable for applications in the automotive and construction industries, where reducing noise and heat is a priority.

Shkathtësia e metal honeycomb cores also extends to their use in high-performance sports equipment, such as bicycle frames and helmets, where both safety and weight reduction are critical factors. These cores are often incorporated into products that require both strength and flexibility, offering a solution to challenges faced by manufacturers across various fields.

Honeycomb for EMI Shielding: Protecting Sensitive Electronics

Honeycomb for EMI shielding is increasingly being used in modern electronics to protect sensitive components from electromagnetic interference (EMI). The honeycomb structure acts as a natural barrier to electromagnetic waves, preventing them from affecting the performance of electronic devices. This shielding technology is critical in ensuring the reliability of high-performance equipment, especially in industries like telecommunications, aerospace, and medical devices.

Duke përdorur honeycomb for EMI shielding provides numerous advantages, including a significant reduction in the size and weight of shielding materials without sacrificing their effectiveness. The structure’s open cells create a protective grid that blocks external EMI while allowing internal components to remain undisturbed. This is crucial in applications such as military communications, satellite technology, and medical imaging, where interference could compromise the integrity of the device or system.

Përdorimi i honeycomb for EMI shielding is not limited to just protecting devices; it also improves the overall performance of systems by ensuring that signals are transmitted clearly and without distortion. Whether you're designing a new piece of equipment or upgrading an existing one, incorporating honeycomb for EMI shielding can enhance the reliability and longevity of your devices.

Steel Honeycomb Sheets FAQs

What are the main benefits of using steel honeycomb sheets in aerospace applications?

Fletët e huallit prej çeliku offer a combination of high strength and low weight, making them ideal for aerospace components that require structural support without adding excess weight. Their corrosion resistance and durability also ensure long-lasting performance in harsh environments.

How does the honeycomb core in steel doors improve security?

Të dyer çeliku me bërthamë mjalti offer enhanced impact resistance, making them more secure against forced entry. Additionally, the honeycomb structure provides superior insulation properties, ensuring both security and temperature control.

Why are steel honeycomb laser beds important in manufacturing?

Steel honeycomb laser beds provide stable and durable surfaces for laser cutting, ensuring high precision and minimizing material distortion. Their strength-to-weight ratio enhances performance, making them essential for industries that require exacting standards in their production processes.

What advantages does the metal honeycomb core offer for construction and automotive applications?

Metal honeycomb cores provide a lightweight, yet strong, solution for applications in construction and automotive industries. They improve structural integrity without adding unnecessary weight, offering a combination of strength, thermal insulation, and soundproofing properties.

How does honeycomb for EMI shielding protect electronic devices?

Honeycomb for EMI shielding acts as a barrier to electromagnetic interference, ensuring that sensitive components within electronic devices function without disruption. It reduces the size and weight of shielding materials while maintaining high effectiveness, making it ideal for use in telecommunications, aerospace, and medical equipment.

As industries evolve, the demand for high-performance materials that offer strength, lightness, and functionality continues to grow. Fletët e huallit prej çeliku, dyer çeliku me bërthamë mjalti, steel honeycomb laser beds, metal honeycomb cores, dhe honeycomb for EMI shielding are transforming the way engineers and manufacturers approach complex design challenges. These materials offer a winning combination of durability, reduced weight, and performance across a variety of sectors, from aerospace to electronics.

If you're looking to incorporate these innovative materials into your next project, look no further. Visit our website today to explore our range of honeycomb solutions that will elevate your designs and performance to the next level. Whether you are in aerospace, automotive, construction, or electronics, we have the materials you need to succeed. Don’t wait—reach out now and get started!

Kategoritë e produkteve

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsLajmeJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionLajmeJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsLajmeJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionLajmeJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsLajmeJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsLajmeJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlLajmeJul.11,2025