- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Ƙarfin Ramin Ruwan Ruwan Zuma: Zane, Aiki, Da Ƙirƙiri

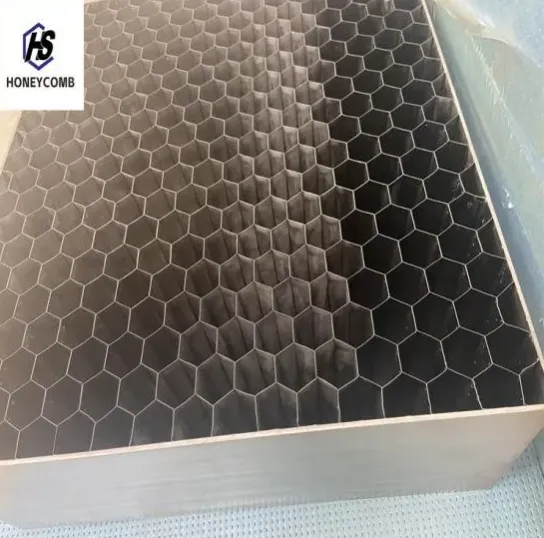

Ramin iska wani ginshiƙi ne a masana'antu tun daga sararin samaniya zuwa na kera motoci, inda daidaitattun kwararar iska da ma'aunin matsi suke da mahimmanci. Daga cikin mafi sabbin abubuwan da ke cikin waɗannan saitin shine ramin saƙar zuma, a highly effective solution for controlling airflow and improving testing accuracy. This article explores the role of honeycomb design in wind tunnels, the impact of bakin karfe saƙar zuma materials, and how a DIY airflow straightener can optimize performance in smaller applications.

Fahimtar Tsarin Ramin Ruwan Ruwan Zuma don Mafi kyawun kwararar iska

The tsarin ramin zumar iska yana taka muhimmiyar rawa wajen tabbatar da tafiyar iska mai santsi, laminar. Ta hanyar yin amfani da tsarin saƙar zuma a ƙofar ramin iska, ana daidaita yanayin iska da kuma tsara shi kafin isa wurin gwaji. Wannan yana haifar da ƙarin ingantattun sakamakon gwaji da kyakkyawar fahimtar yanayin iska na abubuwa daban-daban.

Geometry na ƙwayoyin saƙar zuma yana taimakawa wajen rage tashin hankali da daidaita yanayin iska, wanda ke da mahimmanci don ma'auni daidai a cikin gwaje-gwaje. Ko kuna gwada samfuran sararin samaniya ko masana'antar kera motoci, wannan fasalin ƙirar yana tabbatar da cewa ana sarrafa iska, yana rage kurakurai a cikin bayanan da zasu iya tasowa daga magudanar ruwa marasa tsari.

Matsayin Karfe Bakin Karfe na zuma a cikin Aikace-aikacen Ramin Iska

Kayan zuma bakin karfe kyakkyawan zaɓi ne na kayan aiki don aikace-aikacen ramin iska saboda ƙarfinsa, ƙarfinsa, da juriya ga lalata. A cikin ramukan iska, ana amfani da sifofin saƙar zuma na bakin karfe ba kawai don daidaitawar iska ba har ma a matsayin wani abu mai kariya don tabbatar da dawwamar tsarin.

Amfani da bakin karfe saƙar zuma ensures that the wind tunnel remains stable and unaffected by external elements, such as moisture and temperature fluctuations. The material’s resilience and ability to withstand high-pressure conditions make it an ideal component for high-performance wind tunnels, where accuracy and reliability are paramount.

For those looking to enhance their wind tunnel setup without a significant investment, building a DIY airflow straightener can be a rewarding project. By constructing a custom honeycomb structure, you can improve airflow quality and control in small-scale wind tunnels used for personal or experimental purposes.

The process of making a DIY air flow straightener involves selecting the right materials, such as a honeycomb sheet or mesh, and integrating it into the air intake area of your wind tunnel. You can even adjust the cell size of the honeycomb to fine-tune the airflow characteristics based on your specific requirements. This hands-on approach provides an affordable yet highly effective solution to improve wind tunnel performance.

Haɓaka Daidaiton Gwaji tare da Fasahar Ramin Ramin Ruwan Zuma

In any wind tunnel setup, ensuring that the airflow is as uniform as possible is key to obtaining accurate and repeatable results. The ramin saƙar zuma an tabbatar da ƙira don haɓaka daidaiton gwaji ta hanyar samar da daidaitattun yanayin kwararar iska. Wannan yana da mahimmanci musamman a masana'antu kamar sararin samaniya, inda dole ne a auna kaddarorin sararin samaniya da madaidaici.

Ta hanyar haɗa tsarin saƙar zuma, abubuwan gwaji irin su samfuran jirgin sama ko samfuran mota suna fuskantar kwararar iska iri ɗaya, yana sa sakamakon ya zama abin dogaro kuma yana rage yuwuwar rashin daidaituwa da ya haifar da tashin hankali. The ramin saƙar zuma shaida ce ga mahimmancin kula da zirga-zirgar iska a cikin cimma nasarar ƙirƙira a cikin aikin injiniya.

Daga Ra'ayi zuwa Ƙirƙirar: Juyin Halitta na Tsarin saƙar zuma a cikin Ramin Iska

The tsarin ramin zumar iska ya yi nisa tun farkonsa, yana tasowa tare da ci gaban kimiyyar kayan aiki da injiniyanci. Asalin da aka yi amfani da shi a cikin sauƙi, ƙananan aikace-aikace, ƙirar saƙar zuma yanzu sun zama daidaitattun sifofi a cikin manyan hanyoyin iska na fasaha, godiya ga iyawar su don haɓaka ingancin iska da kuma daidaita gwajin gwaji.

Kamar yadda masana'antu ke tura iyakokin ƙira da gwaji, ruwan zuma bakin karfe ya zama abin da aka fi so saboda ƙayyadaddun kayan aikin injin sa. Tare da haɓakar bugu na 3D da fasahar CNC, ƙirar saƙar zuma ta al'ada yanzu ana ƙirƙira ta da madaidaici fiye da kowane lokaci, tana ba masu ƙira mafi girman sassauci wajen daidaita magudanar iska zuwa takamaiman buƙatu.

Whether you’re exploring the potential of DIY airflow straighteners or upgrading an existing system, the evolution of honeycomb design continues to drive efficiency and innovation in wind tunnel technology.

Rukunin samfuran

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsLabaraiJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionLabaraiJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsLabaraiJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionLabaraiJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsLabaraiJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsLabaraiJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlLabaraiJul.11,2025