- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Poder dos túneis de vento em favo de mel: design, função e inovação

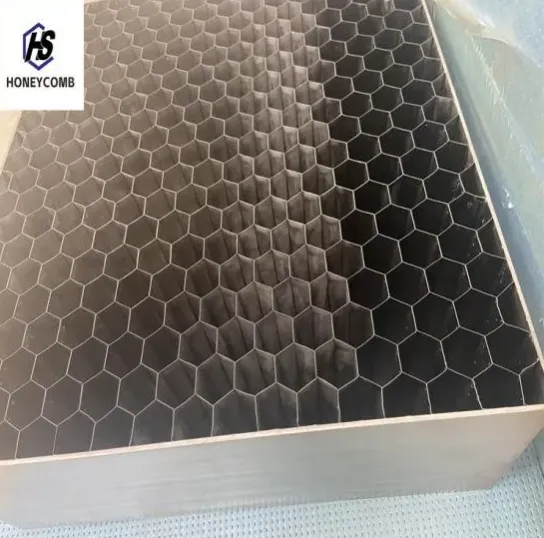

Os túneis de vento são uma pedra angular em indústrias que vão da aeroespacial à automotiva, onde a precisão nas medições de fluxo de ar e pressão são cruciais. Entre os componentes mais inovadores nessas configurações está o túnel de vento em favo de mel, a highly effective solution for controlling airflow and improving testing accuracy. This article explores the role of honeycomb design in wind tunnels, the impact of favo de mel de aço inoxidável materials, and how a DIY airflow straightener can optimize performance in smaller applications.

Compreendendo o projeto do túnel de vento em favo de mel para fluxo de ar ideal

O projeto de túnel de vento em favo de mel desempenha um papel crítico em garantir um fluxo de ar suave e laminar. Ao usar uma estrutura de favo de mel na entrada do túnel de vento, o fluxo de ar é endireitado e organizado antes de atingir a área de teste. Isso leva a resultados de teste mais precisos e a uma melhor compreensão da aerodinâmica de vários objetos.

A geometria das células honeycomb ajuda a reduzir a turbulência e a simplificar o fluxo de ar, o que é essencial para medições precisas em experimentos. Não importa se você está testando modelos para as indústrias aeroespacial ou automotiva, esse recurso de design garante que o fluxo de ar seja controlado, reduzindo erros nos dados que podem surgir de correntes de ar irregulares.

O papel do aço inoxidável tipo colmeia em aplicações de túnel de vento

Aço inoxidável tipo favo de mel é uma excelente escolha de material para aplicações em túneis de vento devido à sua durabilidade, força e resistência à corrosão. Em túneis de vento, estruturas de favo de mel de aço inoxidável são usadas não apenas para endireitar o fluxo de ar, mas também como um elemento de proteção para garantir a longevidade do sistema.

O uso de favo de mel de aço inoxidável ensures that the wind tunnel remains stable and unaffected by external elements, such as moisture and temperature fluctuations. The material’s resilience and ability to withstand high-pressure conditions make it an ideal component for high-performance wind tunnels, where accuracy and reliability are paramount.

For those looking to enhance their wind tunnel setup without a significant investment, building a DIY airflow straightener can be a rewarding project. By constructing a custom honeycomb structure, you can improve airflow quality and control in small-scale wind tunnels used for personal or experimental purposes.

The process of making a DIY air flow straightener involves selecting the right materials, such as a honeycomb sheet or mesh, and integrating it into the air intake area of your wind tunnel. You can even adjust the cell size of the honeycomb to fine-tune the airflow characteristics based on your specific requirements. This hands-on approach provides an affordable yet highly effective solution to improve wind tunnel performance.

Melhorando a precisão dos testes com a tecnologia de túnel de vento em favo de mel

In any wind tunnel setup, ensuring that the airflow is as uniform as possible is key to obtaining accurate and repeatable results. The túnel de vento em favo de mel o design comprovadamente melhora a precisão dos testes ao fornecer condições de fluxo de ar consistentes. Isso é particularmente crucial em indústrias como a aeroespacial, onde as propriedades aerodinâmicas devem ser medidas com extrema precisão.

Ao incorporar uma estrutura de favo de mel, os objetos de teste, como modelos de aeronaves ou protótipos de carros, são submetidos a um fluxo de ar mais uniforme, tornando os resultados mais confiáveis e reduzindo a probabilidade de inconsistências causadas pelo fluxo de ar turbulento. túnel de vento em favo de mel é uma prova da importância do controle do fluxo de ar para alcançar inovação de ponta em engenharia.

Do conceito à criação: a evolução das estruturas de favo de mel em túneis de vento

O projeto de túnel de vento em favo de mel percorreu um longo caminho desde seu início, evoluindo com os avanços na ciência e engenharia de materiais. Originalmente usados em aplicações simples e de pequena escala, os designs de favo de mel são agora um recurso padrão em túneis de vento de alta tecnologia, graças à sua capacidade de melhorar a qualidade do fluxo de ar e agilizar os testes.

À medida que as indústrias ultrapassam os limites do design e dos testes, aço inoxidável tipo favo de mel tornou-se um material preferido devido às suas propriedades mecânicas excepcionais. Com o surgimento da impressão 3D e da tecnologia CNC, os designs de favo de mel personalizados agora estão sendo fabricados com mais precisão do que nunca, oferecendo aos designers maior flexibilidade na adaptação de seus túneis de vento a necessidades específicas.

Whether you’re exploring the potential of DIY airflow straighteners or upgrading an existing system, the evolution of honeycomb design continues to drive efficiency and innovation in wind tunnel technology.

Categorias de produtos

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNotíciasJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNotíciasJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNotíciasJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNotíciasJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNotíciasJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNotíciasJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNotíciasJul.11,2025