- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Kekuwatan Terowongan Angin Honeycomb: Desain, Fungsi, lan Inovasi

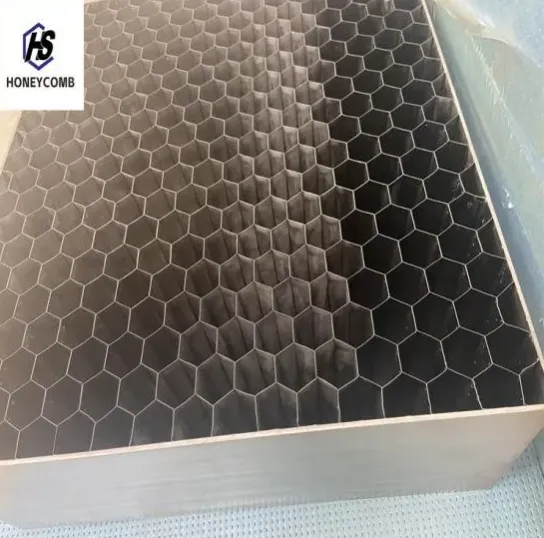

Trowongan angin minangka landasan ing industri wiwit saka aeroangkasa nganti otomotif, ing ngendi presisi ing aliran udara lan pangukuran tekanan penting banget. Antarane komponen sing paling inovatif ing persiyapan iki yaiku trowongan angin honeycomb, a highly effective solution for controlling airflow and improving testing accuracy. This article explores the role of honeycomb design in wind tunnels, the impact of sarang madu stainless steel materials, and how a DIY airflow straightener can optimize performance in smaller applications.

Ngerteni Desain Terowongan Angin Honeycomb kanggo Aliran Udara Optimal

Ing desain honeycomb terowongan angin nduweni peran kritis kanggo njamin aliran udara laminar sing lancar. Kanthi nggunakake struktur honeycomb ing lawang trowongan angin, aliran udara dilurusake lan diatur sadurunge tekan area tes. Iki nyebabake asil tes sing luwih akurat lan pangerten sing luwih apik babagan aerodinamika saka macem-macem obyek.

Geometri sel honeycomb mbantu nyuda turbulensi lan nyepetake aliran udara, sing penting kanggo pangukuran sing tepat ing eksperimen. Apa sampeyan nyoba model kanggo industri aerospace utawa otomotif, fitur desain iki njamin aliran udara dikontrol, nyuda kesalahan ing data sing bisa kedadeyan saka arus udara sing ora teratur.

Peran Baja Tahan Karat Honeycomb ing Aplikasi Terowongan Angin

Baja tahan karat sarang madu minangka pilihan materi sing apik banget kanggo aplikasi trowongan angin amarga daya tahan, kekuatan, lan tahan korosi. Ing trowongan angin, struktur honeycomb stainless steel digunakake ora mung kanggo straightening aliran udara nanging uga minangka unsur protèktif kanggo njamin umur dawa saka sistem.

Panganggone sarang madu stainless steel ensures that the wind tunnel remains stable and unaffected by external elements, such as moisture and temperature fluctuations. The material’s resilience and ability to withstand high-pressure conditions make it an ideal component for high-performance wind tunnels, where accuracy and reliability are paramount.

For those looking to enhance their wind tunnel setup without a significant investment, building a DIY airflow straightener can be a rewarding project. By constructing a custom honeycomb structure, you can improve airflow quality and control in small-scale wind tunnels used for personal or experimental purposes.

The process of making a DIY air flow straightener involves selecting the right materials, such as a honeycomb sheet or mesh, and integrating it into the air intake area of your wind tunnel. You can even adjust the cell size of the honeycomb to fine-tune the airflow characteristics based on your specific requirements. This hands-on approach provides an affordable yet highly effective solution to improve wind tunnel performance.

Nambah Akurasi Pengujian kanthi Teknologi Terowongan Angin Honeycomb

In any wind tunnel setup, ensuring that the airflow is as uniform as possible is key to obtaining accurate and repeatable results. The trowongan angin honeycomb desain kabukten nambah akurasi tes kanthi nyedhiyakake kahanan aliran udara sing konsisten. Iki penting banget ing industri kayata aerospace, ing ngendi sifat aerodinamis kudu diukur kanthi presisi banget.

Kanthi nggabungake struktur honeycomb, subyek tes kayata model pesawat utawa prototipe mobil kena aliran udara sing luwih seragam, nggawe asil luwih dipercaya lan nyuda kemungkinan inkonsistensi sing disebabake dening aliran udara turbulen. Ing trowongan angin honeycomb minangka bukti pentinge kontrol aliran udara kanggo nggayuh inovasi mutakhir ing teknik.

Saka Konsep nganti Penciptaan: Evolusi Struktur Honeycomb ing Terowongan Angin

Ing desain honeycomb terowongan angin wis dawa banget wiwit diwiwiti, berkembang kanthi kemajuan ing ilmu material lan teknik. Originally digunakake ing prasaja, aplikasi cilik, desain honeycomb saiki fitur standar ing dhuwur-tech trowongan angin, thanks kanggo kemampuan kanggo nambah kualitas aliran udara lan streamline testing.

Minangka industri nyurung wates desain lan tes, sarang madu stainless steel wis dadi bahan sing disenengi amarga sifat mekanik sing luar biasa. Kanthi munggah saka printing 3D lan teknologi CNC, desain honeycomb khusus saiki lagi digawe luwih tliti saka tau, nawakake desainer luwih keluwesan kanggo ngatur trowongan angin kanggo kabutuhan tartamtu.

Whether you’re exploring the potential of DIY airflow straighteners or upgrading an existing system, the evolution of honeycomb design continues to drive efficiency and innovation in wind tunnel technology.

Kategori produk

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsKabarJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionKabarJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsKabarJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionKabarJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsKabarJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsKabarJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlKabarJul.11,2025