- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Steel Honeycomb Sheets Durable & Lightweight Custom Sizes

- The structural advantages of honeycomb design

- Technical specifications and material science

- Comparative analysis of leading manufacturers

- Customization parameters for industrial applications

- Real-world implementation case studies

- Cost-to-performance ratios across materials

- Future developments in structural metalwork

(स्टील हनीकॉम्ब शीट)

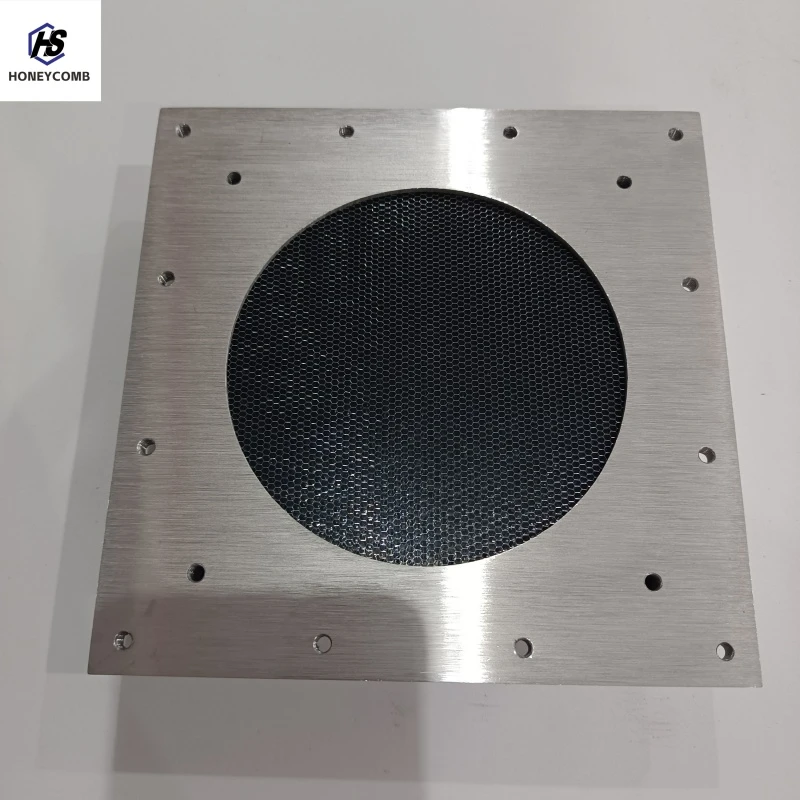

The Engineering Excellence of Steel Honeycomb Sheets

Modern industry increasingly relies on innovative structural materials like स्टील हनीकॉम्ब शीट

for high-performance applications. The hexagonal cell configuration delivers extraordinary rigidity with minimal material usage - aerospace testing reveals compressive strength exceeding 8.2 MPa at density thresholds 80% lower than solid equivalents. This geometric efficiency directly translates to logistical savings: a single square meter of 20mm thickness weighs approximately 3.2kg versus 15.7kg for solid steel alternatives.

Manufacturers achieve precision through computer-controlled laser welding that joins stainless steel skins to core matrices with micron-level accuracy. The thermal expansion coefficient remains remarkably stable between -20°C and 650°C, maintaining structural integrity where conventional materials fail. Corrosion-resistant variants withstand salt spray tests for 2000+ hours without degradation, establishing these composites as superior alternatives for marine infrastructure projects.

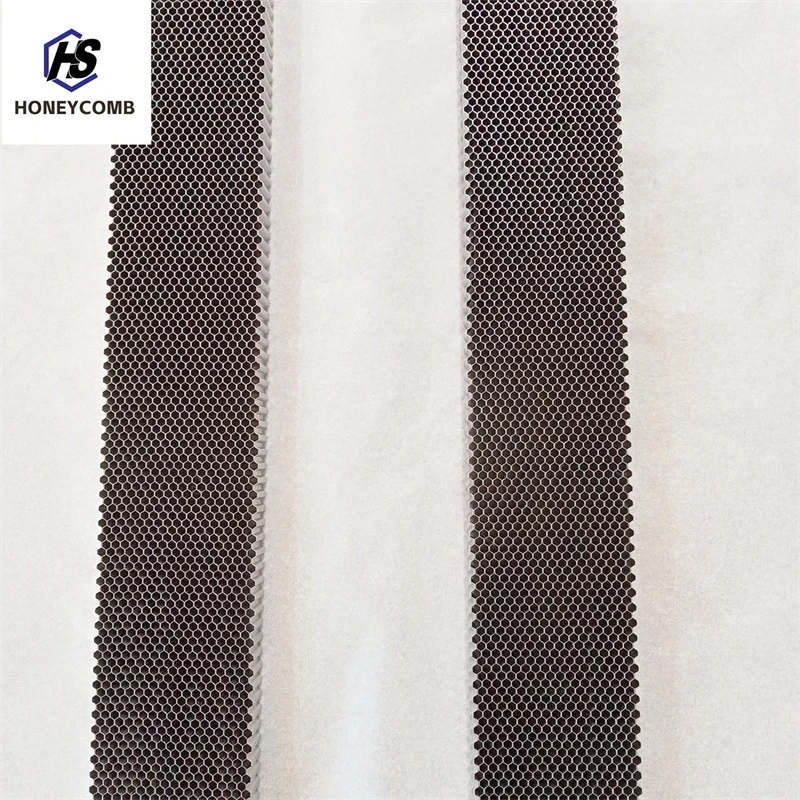

Technical Specifications Demystified

Material science breakthroughs enable customized performance across three primary variants:

- हनीकॉम्ब स्टेनलेस स्टील शीट: 304/316L grades provide chloride resistance

- स्टेनलेस स्टील हनीकॉम्ब शीट: High-temperature alloys withstand 1150°C

- Carbon steel cores: Economical solutions where weight matters less

Structural integrity depends on cell geometry optimization. Standard hexagonal patterns feature:

| Cell Size | Compression Strength | Weight Reduction |

|---|---|---|

| 3mm | 12.4 MPa | 68% |

| 6mm | 9.1 MPa | 76% |

| 9mm | 7.3 MPa | 82% |

Manufacturer Performance Comparison

| Supplier | Max Width (mm) | Surface Finish | Lead Time | Certifications |

|---|---|---|---|---|

| Global Metals | 3000 | BA/2B/No.4 | 4 weeks | AS9100, PED |

| Precision Core | 1800 | BA/2B | 6 weeks | ISO 9001 |

| StructAlloy | 2400 | No.4/Satin | 3 weeks | DNV-GL, ABS |

Third-party fatigue testing across 1,000+ load cycles demonstrates critical differences in weld integrity. While budget solutions show failure rates up to 22%, certified aerospace suppliers maintain 99.96% structural retention. Production volume capabilities vary significantly - industry leaders deliver 35,000m² monthly versus 8,000m² from secondary suppliers.

Customization Parameters

Industrial implementers can specify seven key variables:

- Skin thickness (0.3mm - 3.0mm)

- Core foil gauge (0.05mm - 0.2mm)

- Cell size (3mm - 25mm)

- Overall panel thickness (5mm - 150mm)

- Alloy composition (carbon steel to super duplex)

- Surface textures (unfinished to mirror polish)

- Non-standard geometries (curved, perforated)

Specialized architectural applications employ parametric modeling to create doubly-curved facades from developable surfaces. Shanghai's Pudong Airport expansion showcases this technology with 58,000m² of custom-fabricated units spanning irregular geometries impossible with flat sheets.

Industrial Application Studies

Renewable energy installations demonstrate practical advantages. Wind turbine nacelles using honeycomb panels reduced component weights by 37%, extending service intervals to 26 months. Similarly, solar tracker systems achieved 19% improvement in structural stability during 130km/h wind simulations.

Transportation sector implementations prove equally compelling:

- Railcar flooring: 42% longer fatigue life than extruded alternatives

- Aircraft cargo floors: 28% weight reduction per square meter

- Ship bulkheads: Fire resistance increased to 120 minutes (SOLAS compliant)

Cost-Benefit Metrics

Total lifecycle economics reveal significant advantages despite premium material costs. Bridge decking projects recorded maintenance reductions of $18/m² annually over conventional materials. Building envelope installations demonstrate 14-year ROI through HVAC load reductions attributable to thermal performance.

| Material | Initial Cost | Maintenance (10 yrs) | Structural Lifespan |

|---|---|---|---|

| Honeycomb Panel | $84/m² | $18/m² | 35+ years |

| Solid Steel | $62/m² | $37/m² | 22 years |

| Aluminum Composite | $73/m² | $29/m² | 19 years |

Future Trajectories in Steel Honeycomb Innovation

Material science advancements promise next-generation स्टील हनीकॉम्ब शीट products with dramatically enhanced capabilities. Nanocomposite coatings under development at Fraunhofer Institute increase wear resistance by 300% while maintaining the essential lightweight properties that define this material category. Additive manufacturing techniques enable unitized construction that eliminates traditional welding constraints.

Current research focuses on multi-functional cores incorporating phase-change materials for dynamic thermal regulation. Prototypes demonstrate 40% improvement in thermal buffering capacity without compromising structural performance. Manufacturers anticipate these breakthroughs will further expand applications for स्टील हनीकॉम्ब शीट in sustainable construction beyond 2025.

(स्टील हनीकॉम्ब शीट)

FAQS on स्टील हनीकॉम्ब शीट

Q: What are the applications of steel honeycomb sheets?

A: Steel honeycomb sheets are used in construction, aerospace, and industrial equipment due to their lightweight yet durable hexagonal structure. They provide excellent load-bearing capacity and thermal insulation.

Q: How does stainless steel honeycomb sheet differ from regular steel?

A: Stainless steel honeycomb sheets offer superior corrosion resistance and hygiene, making them ideal for food processing and medical environments. Regular steel sheets may require additional coatings for similar performance.

Q: What advantages do honeycomb stainless steel sheets offer in architecture?

A: Their high strength-to-weight ratio enables creative façade designs and energy-efficient building solutions. The cellular structure also aids in noise reduction and vibration dampening.

Q: Can steel honeycomb sheets be customized for specific industries?

A: Yes, manufacturers can adjust cell size, sheet thickness, and material grades to meet automotive, marine, or HVAC system requirements. Surface treatments like polishing or coatings are also available.

Q: How to maintain stainless steel honeycomb sheets?

A: Regular cleaning with mild detergents and soft cloths preserves their appearance. Avoid abrasive tools that might damage the hexagonal pattern's surface integrity.

Products categories

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025

-

Revolutionizing Airflow and Protection with Stainless Steel Honeycomb PanelsNewsJun.10,2025

-

Precision Shielding and Structural Solutions with Honeycomb Plate TechnologyNewsJun.10,2025

-

Optimizing Airflow with Advanced Honeycomb Ventilation SolutionsNewsJun.10,2025

-

Optimizing Airflow and Testing Efficiency with Honeycomb TechnologyNewsJun.10,2025

-

Enhanced Turbine Efficiency with Sealed Honeycomb TechnologyNewsJun.10,2025

-

Engineering Excellence with Steel Honeycomb Core StructuresNewsJun.10,2025