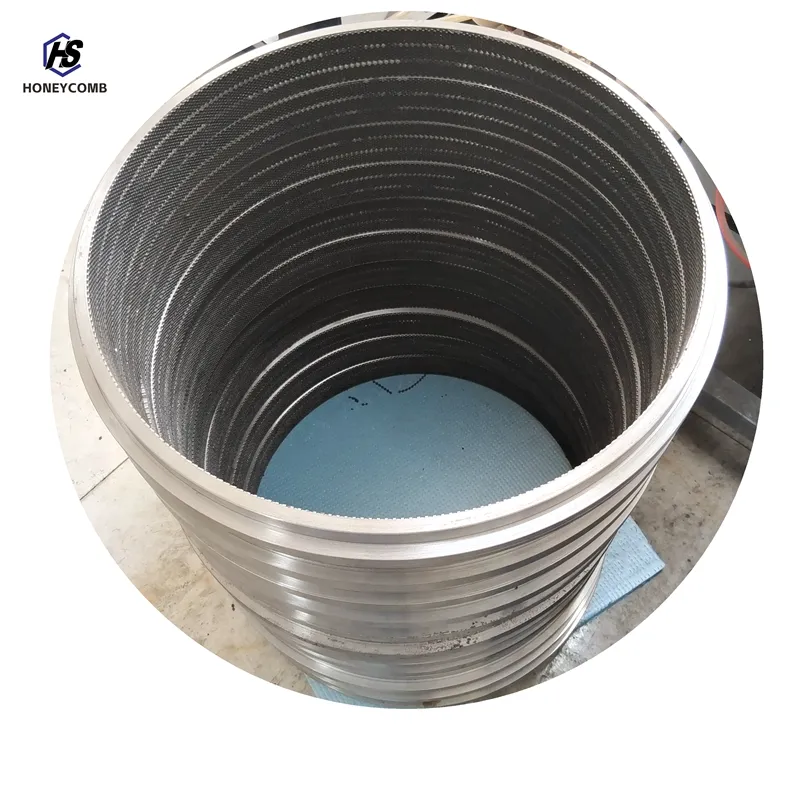

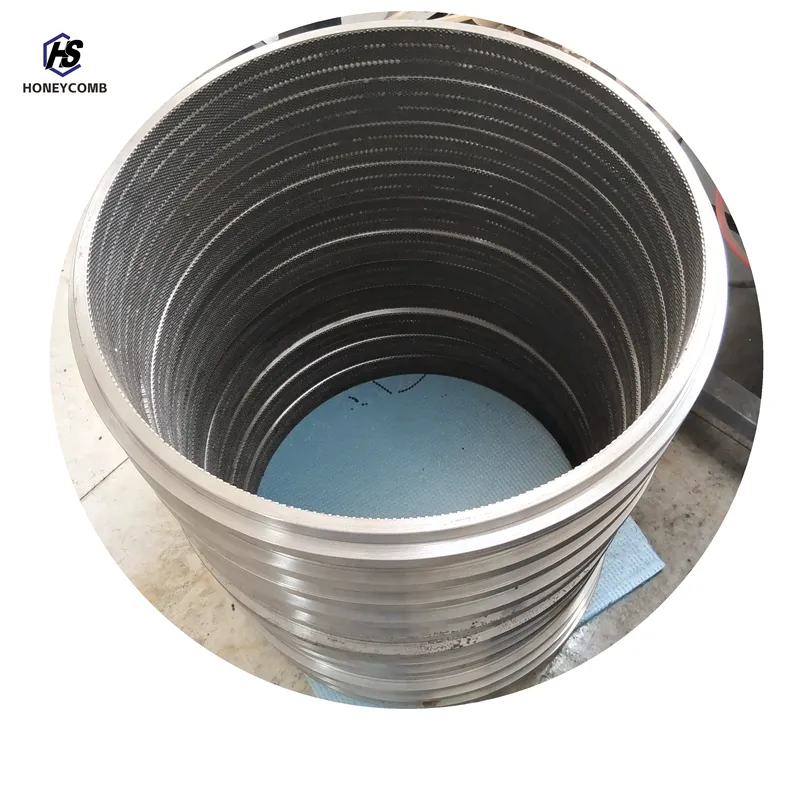

3.2mm Honeycomb Rings

Honeycomb seals are engineered with a unique hexagonal pattern that creates a labyrinth effect, effectively reducing gas leakage in turbine systems. This design minimizes the clearance between rotating and stationary parts, ensuring smoother operation and improved efficiency. The materials used in honeycomb seals, such as high-temperature alloys, further enhance their durability and performance. At [Hengshi honeycomb], we leverage the latest scientific advancements to produce honeycomb seals that deliver unmatched results. Trust our expertise to provide seals that meet the highest industry standards.

Optimized Honeycomb Structure – The 3.2mm cell size ensures a lightweight yet strong sealing barrier for maximum efficiency.

High-Temperature Resistance – Manufactured from stainless steel, Inconel, Hastelloy, or other high-performance alloys, capable of withstanding extreme heat and pressure.

Superior Wear Durability – Designed to endure high-speed friction, mechanical stress, and harsh operating environments.

Enhanced Aerodynamic Sealing – Reduces air leakage, optimizing energy efficiency and system performance.

Corrosion & Oxidation Resistance – Performs reliably in humid, high-pressure, and corrosive conditions.

Customizable Designs – Available in various diameters, materials, and specifications to meet industry-specific needs.

The 3.2mm honeycomb rings are widely used in high-performance machinery and aerospace applications. Common uses include:

Gas Turbines – Enhances sealing efficiency and reduces leakage for improved fuel efficiency.

Jet Engines & Aerospace – Ensures precise sealing under extreme temperature and pressure conditions.

Steam Turbines – Reduces energy loss and improves thermal efficiency in power plants.

Compressors & Pumps – Provides reliable sealing for high-speed rotating machinery.

Industrial Equipment – Used in various high-performance mechanical systems requiring durable and heat-resistant seals.

Advanced Manufacturing – Precision-engineered to tight tolerances for optimal sealing performance.

High-Quality Materials – Made from premium alloys to ensure long-lasting durability.

Improved Machinery Efficiency – Reduces airflow losses, resulting in lower operational costs.

Custom Solutions Available – We offer tailor-made honeycomb rings to match your specific engineering needs.

Competitive Pricing & Fast Shipping – Get high-quality sealing solutions at the best market price with on-time delivery.

Latest news