- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing Solutions

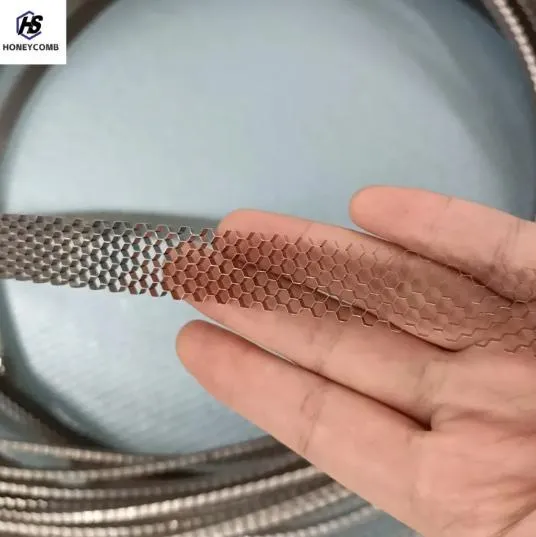

With the evolution of aerospace and power generation technologies, demand is surging for advanced sealing components that can withstand extreme temperatures, resist wear, and improve efficiency. Among the most innovative solutions is the honeycomb strips sealing system—specially designed to meet the rigorous demands of gas turbines, jet engines, compressors, and other high-speed rotating machinery.

Honeycomb Strips: The Key to Sealing High-Speed Rotating Machinery

At the heart of any high-speed rotating machinery lies a constant battle against energy loss and mechanical wear. Honeycomb strips address these challenges with precision-engineered metal structures that function as sacrificial seals. Installed between rotating and stationary components, they reduce leakage and maintain tight tolerances under high-speed conditions.

The open-cell structure of honeycomb strips allows them to deform slightly under operational stress, absorbing wear instead of transferring it to more expensive components like rotors or casings. This makes them ideal for turbines and compressors where even micron-level leakage can lead to significant efficiency loss. Because they’re made from high-temperature alloys, honeycomb strips also perform consistently in hostile thermal environments, often exceeding 1000°C in gas turbines and jet engines.

The Role of Honeycomb Strips in Compressors

When integrated into modern compressors, honeycomb strips improve overall performance and extend the service life of rotating equipment. Unlike traditional seals, these strips enable closer clearances, which in turn minimize air or gas leakage between the rotor and casing. The result is a notable boost in stage efficiency and compression ratio.

Furthermore, the unique cellular geometry of honeycomb strips significantly reduces the risk of catastrophic failure. In case of blade-tip contact, the strip will collapse harmlessly, preventing damage to more valuable rotating components. That’s why honeycomb seals are the preferred option in high-performance compressor stages across aerospace and energy industries.

The low friction and high durability of honeycomb strips also lead to reduced maintenance intervals. This decreases the total lifecycle cost of the compressor, especially in industrial applications that require continuous, high-efficiency operation under demanding conditions.

Advanced Applications of Honeycomb Seals in Gas Turbines

Perhaps the most notable application of honeycomb strips is in the world of power generation. The honeycomb seal gas turbine systems rely heavily on these advanced seals to maintain operational reliability and boost thermal efficiency. Positioned in the turbine’s stator sections, honeycomb seals restrict hot gas flow around turbine blades and minimize leakage paths.

This sealing efficiency allows turbine operators to extract more energy from every combustion cycle. Additionally, the robust build of honeycomb seal gas turbine components allows them to resist oxidation, creep, and fatigue under extreme pressure and temperature fluctuations.

These benefits are not limited to stationary power plants—aviation gas turbines also rely on honeycomb strips to enhance fuel efficiency, increase range, and meet stricter emissions standards. The versatility of these seals allows for use in both axial and radial configurations, adapting easily to various turbine geometries.

What Makes Honeycomb Strips Superior to Conventional Sealing Materials?

Unlike labyrinth seals or brush seals, honeycomb strips combine high temperature resistance with controlled deformation behavior. They provide a non-contact or near-contact sealing solution that remains effective even after minor tip rubs or pressure surges.

The metallic honeycomb structure, typically made from nickel-based superalloys or stainless steel, can withstand prolonged thermal cycling without distortion. This is especially useful in gas turbines and steam turbines, where startup and shutdown cycles can lead to seal fatigue. The honeycomb design distributes stress across multiple cells, limiting localized failures and maintaining sealing integrity over extended operation periods.

In terms of installation, honeycomb strips are typically brazed or bonded onto stator surfaces, offering a secure and precise fit. This ensures performance consistency, whether in new turbine builds or retrofit upgrades. With more companies adopting honeycomb seals as their standard, maintenance personnel now have a reliable and proven solution that demands less frequent inspection and service.

Honeycomb Strips FAQs

What are honeycomb strips made of?

Honeycomb strips are typically manufactured from high-temperature-resistant metal alloys such as Inconel or stainless steel. These materials are selected for their durability, heat resistance, and compatibility with brazing techniques used during installation.

How do honeycomb seals improve turbine performance?

Honeycomb seals reduce leakage and improve the sealing between rotating and stationary components in turbines. This enhances the thermal efficiency of gas turbines, allowing for greater power output and lower fuel consumption.

Are honeycomb strips suitable for jet engines?

Yes, honeycomb strips are widely used in jet engines. Their ability to withstand extreme temperatures and resist erosion makes them ideal for high-speed aerospace applications.

What makes honeycomb seal gas turbine systems more efficient?

The honeycomb seal gas turbine design minimizes hot gas bypass, ensuring more efficient combustion and energy conversion. It also reduces wear on turbine blades, extending component life.

Can honeycomb strips be used in compressors and steam turbines?

Absolutely. Honeycomb strips are used extensively in compressors and steam turbines due to their reliability, flexibility under thermal load, and ability to reduce maintenance downtime.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceNewsJul.11,2025