- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

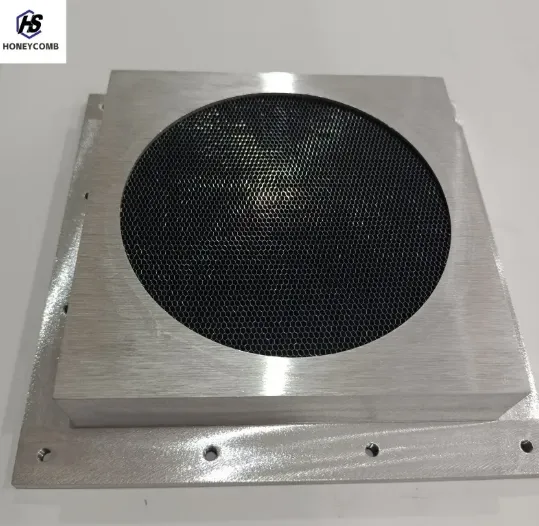

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI Control

With the rapid expansion of electronic systems in aerospace, medical, and military industries, managing airflow and shielding electromagnetic interference (EMI) has become a core design challenge. The vented aluminum honeycomb emerges as a powerful solution—providing robust ventilation while maintaining superior shielding effectiveness against EMI. Lightweight, customizable, and engineered for performance, it plays a vital role in advanced enclosures and shielding assemblies.

How Material Grade Affects Vented Aluminum Honeycomb Performance

The core performance of a vented aluminum honeycomb lies not only in its structure but also in the material grade of aluminum used in its construction. Typically made from 3000 or 5052 series aluminum alloys, the choice of alloy significantly influences strength, corrosion resistance, weight, and electromagnetic shielding capability.

Higher-grade aluminum, such as 5052-H32, enhances mechanical durability and increases the corrosion resistance of the vented aluminum honeycomb, especially in high-moisture environments like marine or coastal locations. It also provides better bonding compatibility for conductive coatings like nickel or tin, which amplify the shielding efficiency of the emi honeycomb.

Meanwhile, using lower-grade alloys may reduce costs but often compromises the mechanical stability and long-term effectiveness of the honeycomb vent. For clients seeking high EMI attenuation and environmental reliability, specifying high-grade aluminum is essential. Surface treatments such as chromate conversion coatings or anodizing can further extend product life and enhance conductivity.

Balancing Ventilation and Electromagnetic Shielding with EMI Honeycomb

One of the most compelling features of the vented aluminum honeycomb is its dual function: allowing air to flow freely through electronic enclosures while blocking harmful EMI from entering or escaping. This balance is particularly important in sensitive equipment such as radar systems, communication cabinets, MRI scanners, and satellite instruments.

The hexagonal geometry of the honeycomb vent offers a unique solution. While open to air movement, the thin conductive walls of each cell act as a waveguide, effectively absorbing or reflecting electromagnetic waves. Depending on the design, an emi honeycomb can deliver shielding effectiveness up to 100 dB in frequencies ranging from 30 MHz to several GHz.

To enhance performance, these vents are often integrated with conductive gaskets or frames, ensuring seamless contact between the vented aluminum honeycomb and the mounting surface. Custom cell sizes, thicknesses, and angles can be designed to match airflow requirements while maximizing shielding efficiency. This customization makes it a preferred choice across aerospace, defense, and precision medical sectors.

Installation Procedures and Safety Precautions for Honeycomb Vent

Correct installation is key to ensuring the performance of a honeycomb vent. Whether installed on a cabinet door, ventilation panel, or instrument chassis, attention to detail ensures long-term function and effectiveness.

First, determine the exact dimensions of the opening and confirm that the vented aluminum honeycomb frame aligns properly with the cutout. Clean the contact surfaces to remove dust, oil, or oxidation that may interfere with grounding or gasket adhesion. Then, insert the honeycomb vent into the frame using screws, clips, or adhesive bonding—depending on the design specifications.

If a conductive gasket is included, ensure full compression between mating surfaces to preserve the shielding continuity. Care must be taken not to deform or compress the cells of the vented aluminum honeycomb, as this may reduce airflow or shielding effectiveness.

Protective gloves should be worn to avoid injury from the sharp cell edges, and anti-static precautions should be observed when handling the emi honeycomb in sensitive environments. Once installed, test the structure for proper grounding and check that no gaps exist around the frame.

Routine inspection is advised to detect any deformation, corrosion, or loose mounting that might impair the integrity of the honeycomb vent over time.

Applications and Customization of Vented Aluminum Honeycomb Systems

The vented aluminum honeycomb serves a wide array of industries where airflow and EMI shielding must coexist. Common applications include:

Server racks and telecommunication cabinets

Military and avionics enclosures

Laboratory and medical devices

EMC test chambers

Base stations and radar shelters

Manufacturers offer a range of customization options to suit each application. Clients can specify the thickness of the emi honeycomb, the direction of airflow (straight vs. angled cells), cell size (typically from 3.2 mm to 6.4 mm), and even the depth of the honeycomb layer.

Frames are available in aluminum, steel, or stainless steel, depending on the mechanical or corrosion requirements of the installation. Flame-retardant finishes and salt-fog-resistant coatings can be applied for extreme environments. Some suppliers also integrate air filters or mesh screens within the honeycomb vent, providing particle filtration in addition to EMI shielding and ventilation.

From design consulting to prototype development, the flexibility and efficiency of the vented aluminum honeycomb make it an essential component in high-tech systems that demand both environmental control and electromagnetic protection.

Vented Aluminum Honeycomb FAQs

What is the main function of a vented aluminum honeycomb?

It allows cooling airflow into sensitive enclosures while shielding against electromagnetic interference, making it ideal for electronic cabinets and military equipment.

How does an emi honeycomb block electromagnetic interference?

The conductive walls of its hexagonal cells act as a Faraday cage, reflecting and absorbing EMI, with effectiveness up to 100 dB depending on the design.

What materials are used in a high-quality honeycomb vent?

Most are made from 3000 or 5052 series aluminum alloys, with surface treatments like tin, nickel, or chromate coatings for conductivity and corrosion resistance.

Can I customize the size and shape of my vented aluminum honeycomb?

Yes. Manufacturers offer complete customization including cell size, depth, airflow angle, and frame material to match your specific requirements.

What precautions should I take during installation of a honeycomb vent?

Ensure clean, conductive contact surfaces, use proper mounting tools, avoid damaging the cells, and confirm continuous grounding to preserve EMI shielding.

Products categories

-

Advanced Honeycomb Gas Seal: Maximize Efficiency & ReliabilityNewsAug.31,2025

-

1.6mm Honeycomb Ring Seal: High-Performance, Reliable SealingNewsAug.30,2025

-

Steel Honeycomb CoreNewsAug.29,2025

-

Stainless Steel Honeycomb SheetNewsAug.29,2025

-

Honeycomb SealNewsAug.29,2025

-

2.5mm Honeycomb Seal: High-Performance, Durable Sealing SolutionsNewsAug.29,2025

-

2.5mm Honeycomb Seal - High-Performance & Durable Sealing SolutionsNewsAug.28,2025