- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Stainless Steel Honeycomb Panel: The Shielding Solution for Tough Environments

As technology advances and electromagnetic interference (EMI) becomes a growing concern in defense, aerospace, and communication sectors, materials that provide both structural durability and high EMI/RF shielding performance are in high demand. Among them, the stainless steel honeycomb panel stands out as a premium solution. Combining strength, stability, and exceptional shielding, this material is rapidly becoming the go-to choice for engineers seeking performance without compromise.

Unmatched Strength and Stability in Stainless Steel Honeycomb Panel Design

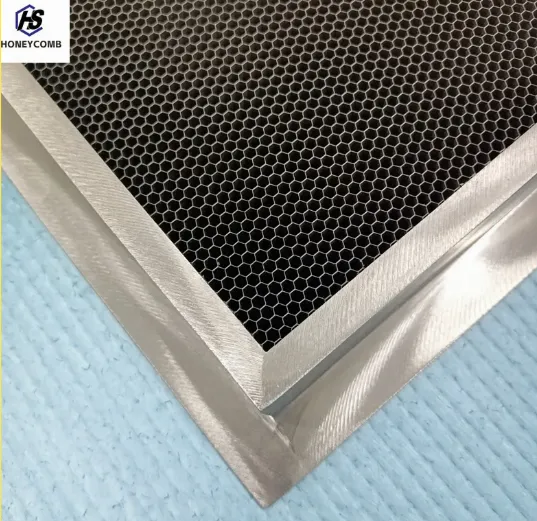

What sets the stainless steel honeycomb panel apart from other honeycomb materials is its core advantage: extreme mechanical strength and resistance to deformation. Made from high-grade stainless steel, these panels feature a symmetrical honeycomb core structure that distributes stress evenly, reduces weight without sacrificing performance, and provides long-term durability under demanding conditions.

Unlike aluminum-based alternatives, the stainless steel honeycomb panel resists corrosion, oxidation, and impact damage. This makes it ideal for applications where environmental factors—such as moisture, temperature extremes, and mechanical stress—pose a serious challenge. Whether used in exterior architectural cladding, military shelters, or industrial enclosures, the material holds its shape, strength, and integrity for decades.

Moreover, stainless steel’s non-porous surface ensures hygienic properties, making these panels well-suited for clean rooms and high-sterility environments. Their low maintenance requirements and compatibility with both welding and adhesive bonding further simplify installation across various industries.

How Stainless Steel Honeycomb Panels Provide Superior EMI/RF Shielding

The stainless steel honeycomb panel is not just a structural component—it is a powerful shield against electromagnetic radiation. Its superior EMI/RF shielding comes from the high electrical conductivity of stainless steel, combined with the depth and geometry of the honeycomb core. Each small cell functions as a waveguide, attenuating incoming electromagnetic waves and preventing signal leakage.

Unlike perforated sheets or metal screens, the honeycomb configuration ensures continuous conductive pathways in all directions. The multiple internal reflections within the stainless steel honeycomb mesh reduce high-frequency interference, achieving shielding effectiveness levels that exceed 100 dB in many configurations.

In military command centers, radar installations, and secure data facilities, the stainless steel honeycomb panel is trusted for its ability to isolate sensitive electronics from disruptive EMI. When mounted properly within shielded enclosures or rooms, these panels create Faraday-cage-like protection, ensuring critical systems operate without disruption.

Additional benefits include fire resistance and low smoke emission, which are essential for transportation and aerospace applications. Unlike plastic-based shielding solutions, stainless steel does not degrade over time or pose a fire hazard under intense thermal stress.

The Role of Stainless Steel Honeycomb Mesh in Custom Enclosures

The stainless steel honeycomb mesh plays a pivotal role in custom shielding designs. Often fabricated as vent panels or integrated into doors and hatches, this mesh allows for air passage without compromising electromagnetic shielding. It’s the perfect choice for server cabinets, EMI filters, and HVAC inlets within secure rooms.

Available in a variety of cell sizes and thicknesses, the stainless steel honeycomb mesh can be tailored to meet precise airflow and shielding specifications. Whether mounted in frames or installed with conductive gaskets, its flexibility supports the design of both static and removable shielding structures.

Clients can select the mesh based on frequency attenuation targets, mechanical load requirements, or air resistance limits. In clean room environments, the non-shedding and rust-proof nature of stainless steel ensures consistent performance and regulatory compliance.

Even more, the stainless steel honeycomb sheet can be laser-cut or water-jet processed to exact shapes for tight-fitting assemblies. This allows for seamless integration into panels, racks, or bulkheads while maintaining shielding continuity and mechanical protection.

Expanding Applications of Stainless Steel Honeycomb Sheet Across Industries

From telecommunications to medical imaging, the stainless steel honeycomb sheet is playing a larger role in the protection of sensitive electronics and equipment. It is frequently used in MRI shielding rooms, EMC test chambers, transportation enclosures, and industrial control centers—anywhere high-frequency signals need to be controlled or contained.

Aerospace engineers value the stainless steel honeycomb sheet for its thermal tolerance, dimensional stability, and compatibility with composite skins in aircraft paneling. Similarly, defense contractors utilize the material in ruggedized enclosures and mobile command systems where physical strength and signal isolation are equally critical.

Architects are also adopting the material for building envelopes and security doors where aesthetic finishes must pair with EMI shielding. The brushed or mirror-polished surface of the stainless steel honeycomb panel offers both visual appeal and long-term resilience, making it ideal for both functional and decorative installations.

Customization is key: clients can choose from various stainless steel grades (such as 304 or 316L), cell sizes, face sheet thicknesses, and coatings depending on the application. Some panels are even combined with carbon steel or aluminum backings for hybrid strength and weight profiles.

Stainless Steel Honeycomb Panel FAQs

What is a stainless steel honeycomb panel used for?

It’s used in EMI shielding, aerospace panels, security doors, and industrial enclosures where strength and electromagnetic protection are essential.

How does the stainless steel honeycomb mesh provide EMI shielding?

The conductive stainless steel and honeycomb cell structure reflect and absorb electromagnetic waves, blocking interference while allowing airflow.

What is the difference between a stainless steel honeycomb sheet and a standard metal sheet?

The honeycomb sheet is lighter, stronger, and provides better EMI shielding due to its cellular core, whereas standard sheets are solid and heavier.

Can I customize my stainless steel honeycomb panel for my application?

Yes. You can select the thickness, core size, surface finish, and even request framed or gasketed versions for easy installation.

Why choose stainless steel over aluminum in honeycomb panels?

Stainless steel offers higher strength, better corrosion resistance, superior fire performance, and longer life in extreme conditions.

Products categories

-

Stainless Steel Honeycomb Air Straightener IntakeNewsSep.01,2025

-

Advanced Honeycomb Gas Seal: Maximize Efficiency & ReliabilityNewsAug.31,2025

-

1.6mm Honeycomb Ring Seal: High-Performance, Reliable SealingNewsAug.30,2025

-

Steel Honeycomb CoreNewsAug.29,2025

-

Stainless Steel Honeycomb SheetNewsAug.29,2025

-

Honeycomb SealNewsAug.29,2025

-

2.5mm Honeycomb Seal: High-Performance, Durable Sealing SolutionsNewsAug.29,2025