- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

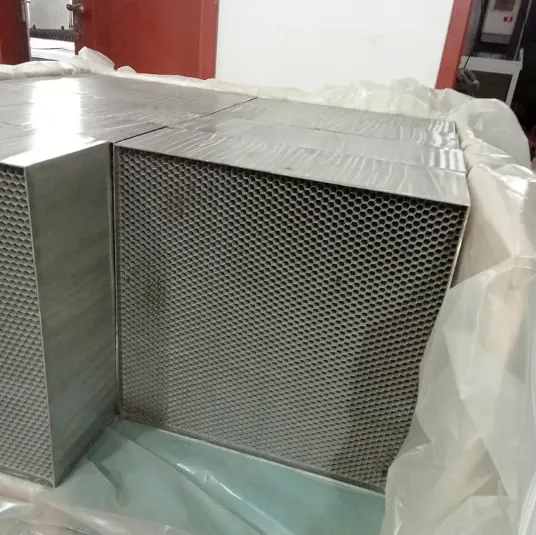

Honeycomb Wind Tunnel: Precision Flow Control Starts Here

A high-performance honeycomb wind tunnel is the key to creating stable, streamlined airflow for precise aerodynamic testing across aviation, automotive, and industrial applications.

How Finite Element Analysis Enhances Honeycomb Wind Tunnel Performance

To create consistent laminar flow, the structural design of a honeycomb wind tunnel must be optimized using finite element analysis (FEA). FEA allows engineers to model and evaluate the stress, pressure resistance, and flow characteristics of the honeycomb grid before physical production. These simulations ensure the tunnel can handle high-velocity air without deformation or vibration.

The cell structure, wall thickness, and bonding techniques of the wind tunnel honeycomb are analyzed in virtual environments, helping to predict performance under thermal and aerodynamic stress. The result is a lightweight yet highly stable configuration that delivers low turbulence, minimal flow distortion, and durable mechanical integrity.

By using FEA, manufacturers can design each honeycomb air flow straightener to achieve optimal length-to-diameter ratios, improving flow uniformity without sacrificing efficiency. This guarantees more reliable aerodynamic testing and repeatable data collection, even in high-speed tunnels.

How to Repair a Damaged Honeycomb Wind Tunnel Structure

While honeycomb wind tunnel systems are built for longevity, damage can occur due to impact, corrosion, or operational accidents. When repair is needed, the modular structure of most systems makes maintenance easier and more cost-effective.

First, damaged panels or sections of the wind tunnel honeycomb are isolated and removed. Minor dents can often be reshaped or filled with compatible resin, while cracked or crushed honeycomb cells are replaced with matching inserts. High-strength adhesives are used to secure the replacement material and maintain airflow consistency.

In more advanced systems, diagnostic tools like ultrasonic scanning or airflow visualization may be used to verify internal damage or confirm alignment after repair. After reinstallation, airflow testing ensures the honeycomb air flow straightener delivers its original aerodynamic function, maintaining precision across the tunnel’s testing envelope.

Correcting Airflow Direction with Honeycomb Air Flow Straightener Units

The primary role of a honeycomb air flow straightener is to eliminate crosswinds and align the air movement in a uniform direction. Over time or after extended use, misalignment or deformation of these units can cause minor disturbances in the flow field, which can compromise test data.

Correction begins by analyzing downstream velocity profiles using tools like laser Doppler velocimetry. If off-axis flow is detected, the wind tunnel honeycomb panels are either adjusted or replaced based on flow angle deviations. The airflow direction is restored by fine-tuning the orientation and structure of the honeycomb cores, ensuring every cell acts as a directional guide for the incoming air.

Some systems also allow for modular adjustment, giving technicians the ability to swap out sections of the honeycomb wind tunnel depending on the desired flow regime—subsonic, transonic, or supersonic—making real-time corrections faster and more precise.

Why Customized Wind Tunnel Honeycomb Design Enhances Testing Accuracy

A custom-engineered wind tunnel honeycomb design offers a distinct advantage over generic flow straighteners. Tailored designs consider tunnel size, test speed, material type, and environmental conditions, ensuring optimal performance in every scenario.

Materials like aluminum, aramid fiber (Nomex), and polycarbonate are selected for their unique combinations of strength, weight, and corrosion resistance. The cell structure—often hexagonal or square—along with the length-to-diameter ratio, is fine-tuned to deliver superior flow correction with minimal pressure loss.

Compared to traditional screen-based flow conditioners, a properly engineered honeycomb wind tunnel delivers significantly better cross-flow elimination and directionality. Facilities investing in this level of precision can expect consistent test outcomes, lower data variability, and improved efficiency across all aerodynamic evaluations.

Honeycomb Wind Tunnel FAQs

What materials are most commonly used in a honeycomb wind tunnel?

Most systems use aluminum, Nomex, or polycarbonate, depending on the required strength, thermal stability, and corrosion resistance.

How does a honeycomb air flow straightener improve wind tunnel accuracy?

It eliminates lateral airflow disturbances and aligns the flow, ensuring consistent, laminar air for more reliable aerodynamic measurements.

Can a damaged wind tunnel honeycomb section be replaced without removing the entire panel?

Yes, modular systems allow individual segments or panels to be replaced or repaired without disrupting the entire tunnel setup.

How often should airflow correction be performed on a honeycomb wind tunnel?

Periodic checks are recommended every 6–12 months depending on usage frequency, especially if high-speed testing is involved.

What factors influence a successful wind tunnel honeycomb design?

Key factors include material choice, cell size and shape, length-to-diameter ratio, and integration with upstream flow conditioners.

Products categories

-

Stainless Steel Honeycomb Air Straightener IntakeNewsSep.01,2025

-

Advanced Honeycomb Gas Seal: Maximize Efficiency & ReliabilityNewsAug.31,2025

-

1.6mm Honeycomb Ring Seal: High-Performance, Reliable SealingNewsAug.30,2025

-

Steel Honeycomb CoreNewsAug.29,2025

-

Stainless Steel Honeycomb SheetNewsAug.29,2025

-

Honeycomb SealNewsAug.29,2025

-

2.5mm Honeycomb Seal: High-Performance, Durable Sealing SolutionsNewsAug.29,2025