- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation Solutions

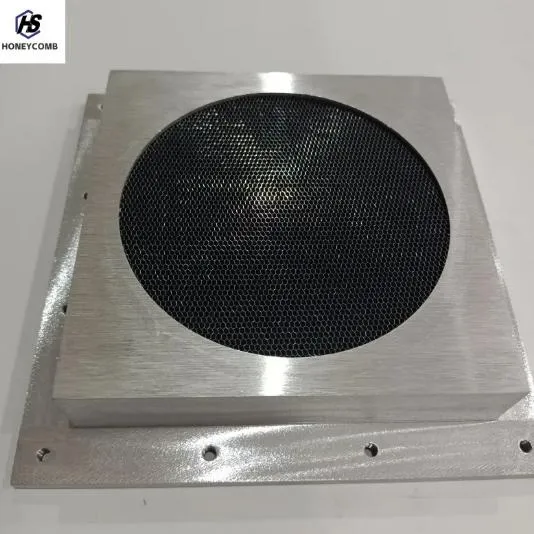

In today's high-performance industries, precision airflow, electromagnetic shielding, and durability are essential. Vented aluminum honeycomb stands out as a game-changer by combining lightweight strength, excellent airflow, and unmatched EMI shielding performance in one solution. Its versatile design and customizable configuration make it indispensable for applications in aerospace, military systems, telecom infrastructure, and advanced electronics.

How Vented Aluminum Honeycomb Surpasses Traditional Ventilation Materials

When comparing modern solutions to older systems, vented aluminum honeycomb easily outperforms traditional materials like mesh screens, steel grates, or punched metal plates. While older options provide basic ventilation, they lack the shielding efficiency required in environments with sensitive electronics. Honeycomb vent panels, in contrast, offer both superior air transfer and reliable electromagnetic interference control.

The structure of vented aluminum honeycomb features tightly packed metallic cells that allow airflow to pass while blocking EMI signals. Its strength-to-weight ratio is significantly higher than sheet metal, making it ideal for weight-sensitive aerospace and transport projects. Whether installed in server racks, avionics systems, or military enclosures, honeycomb vent products outperform conventional vents in both durability and function.

Optimizing Shielding with the Right Hole Shape in EMI Honeycomb Panels

The shielding effectiveness of emi honeycomb is heavily influenced by the shape of its internal cells. While both circular and hexagonal holes are common in manufacturing, each has a different performance profile. Circular cell structures tend to prioritize airflow, making them excellent for cooling systems that demand volume ventilation.

However, for applications where EMI attenuation is critical, hexagonal cells in emi honeycomb offer a tighter, denser configuration. This shape blocks more electromagnetic radiation and increases signal shielding. For instance, military electronics enclosures often specify hexagonal honeycomb vent structures due to their consistent shielding across wide frequency ranges.

In the world of vented aluminum honeycomb, choosing the right hole shape becomes a balancing act between cooling efficiency and electromagnetic protection. Fortunately, manufacturers can customize both the cell geometry and the dimensions to achieve optimal results for specific industry needs.

Understanding the Opening Rate of Vented Aluminum Honeycomb and Its Performance

The opening rate—or the percentage of open space in the panel—is another critical factor affecting the performance of vented aluminum honeycomb. A higher opening rate results in better airflow, making it ideal for systems needing intensive cooling. However, this also reduces the shielding capacity slightly.

Conversely, a lower opening rate increases the EMI attenuation in emi honeycomb panels, which is perfect for secure environments where signal leakage could pose a risk. For applications that need a balance of both, like data centers or avionics enclosures, mid-range opening rates on honeycomb vent panels provide sufficient airflow while still meeting strict shielding requirements.

These customization options are one of the main reasons engineers turn to vented aluminum honeycomb products. Whether you need thermal dissipation, airflow regulation, or maximum shielding, the opening rate can be adjusted precisely to your specifications.

Application Versatility and System Integration with EMI Honeycomb

In addition to high-performance shielding and ventilation, emi honeycomb panels offer several mechanical advantages. They’re naturally resistant to corrosion, capable of withstanding temperature extremes, and can be treated with anodizing, plating, or powder-coating for even more durability.

From telecom shelters to radar systems and aerospace modules, emi honeycomb inserts easily into enclosures or can be surface-mounted as air intake filters. They’re commonly used in conjunction with gaskets and frames for added protection. Furthermore, vented aluminum honeycomb structures help minimize acoustic noise and thermal buildup, supporting longer lifespans for sensitive equipment.

Industries that demand reliability, especially military and communications, benefit from the seamless integration of honeycomb vent systems. The combination of airflow, shielding, and structural stability in a single product makes vented aluminum honeycomb the superior choice.

Vented Aluminum Honeycomb FAQs

What makes vented aluminum honeycomb better than standard metal mesh?

Unlike mesh screens, vented aluminum honeycomb combines strength, precision airflow, and EMI shielding in a lightweight design. It resists corrosion, handles high pressure, and is ideal for electronic protection and cooling systems.

What’s the advantage of hexagonal cells in emi honeycomb?

Hexagonal cells in emi honeycomb offer tighter packing and better electromagnetic wave attenuation. This design increases the shielding effectiveness and is preferred for high-frequency applications.

Can the opening rate in honeycomb vent panels be customized?

Yes. The opening rate of honeycomb vent panels can be tailored to match airflow and shielding requirements, providing application-specific solutions for every industry.

Are vented aluminum honeycomb panels corrosion-resistant?

Absolutely. Vented aluminum honeycomb is made from corrosion-resistant aluminum and can be treated further with anodizing or coatings, making it suitable for marine, military, and outdoor applications.

How is emi honeycomb used in the telecommunications industry?

Emi honeycomb panels are installed in equipment enclosures, server rooms, and communication towers to block EMI while allowing heat dissipation. Their compact design and superior shielding make them essential for maintaining signal integrity.

Products categories

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceNewsJul.11,2025