- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 21, 2025 02:18

Back to list

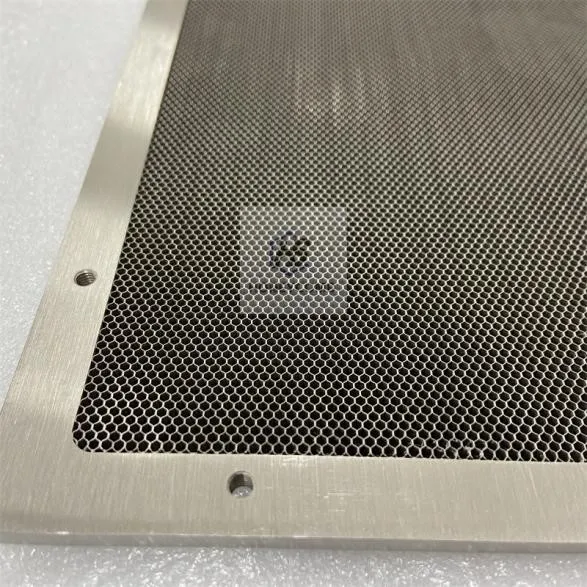

maf honeycomb screen

The steel honeycomb laser bed is revolutionizing industries that require precision and robustness. Picture a bed designed with the intricacies of a honeycomb structure but made entirely of high-strength steel. This unique combination is not only innovative but also incredibly practical for industries like automotive, aerospace, and high-precision manufacturing, which demand unparalleled accuracy and stability.

Expert endorsement comes from numerous industry leaders who acknowledge the strategic advantage offered by such technological integration. It is no surprise that many manufacturing giants have pivoted to adopt steel honeycomb beds to maintain a competitive edge. By doing so, they position themselves not just as industry participants but as innovators steering the future of manufacturing technology. Trust plays an integral role in the adoption of new technology, and the track record of steel honeycomb laser beds instills confidence among users. These beds are subjected to rigorous testing under various operational conditions to gauge their performance and durability. Moreover, recognition from standards organizations and positive reviews from early adopters further solidify the trust in this cutting-edge product. The steel honeycomb laser bed thus represents a fusion of advanced material science and precise engineering. It's a prime example of how reimagining conventional designs with modern materials can lead to significant improvements in performance and reliability. Industries adopting this technology can expect not only immediate benefits in terms of precision and efficiency but also long-term advantages as their reputations for quality and innovation grow. In conclusion, for businesses looking to stay ahead in precision manufacturing, investing in a steel honeycomb laser bed is not merely an option but a strategic imperative. It embodies the pinnacle of engineering excellence, combining strength, precision, and dependability in a single solution that addresses the ever-evolving demands of modern industry.

Expert endorsement comes from numerous industry leaders who acknowledge the strategic advantage offered by such technological integration. It is no surprise that many manufacturing giants have pivoted to adopt steel honeycomb beds to maintain a competitive edge. By doing so, they position themselves not just as industry participants but as innovators steering the future of manufacturing technology. Trust plays an integral role in the adoption of new technology, and the track record of steel honeycomb laser beds instills confidence among users. These beds are subjected to rigorous testing under various operational conditions to gauge their performance and durability. Moreover, recognition from standards organizations and positive reviews from early adopters further solidify the trust in this cutting-edge product. The steel honeycomb laser bed thus represents a fusion of advanced material science and precise engineering. It's a prime example of how reimagining conventional designs with modern materials can lead to significant improvements in performance and reliability. Industries adopting this technology can expect not only immediate benefits in terms of precision and efficiency but also long-term advantages as their reputations for quality and innovation grow. In conclusion, for businesses looking to stay ahead in precision manufacturing, investing in a steel honeycomb laser bed is not merely an option but a strategic imperative. It embodies the pinnacle of engineering excellence, combining strength, precision, and dependability in a single solution that addresses the ever-evolving demands of modern industry.

Prev:

Products categories

Latest news

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025

-

Revolutionizing Airflow and Protection with Stainless Steel Honeycomb PanelsNewsJun.10,2025

-

Precision Shielding and Structural Solutions with Honeycomb Plate TechnologyNewsJun.10,2025

-

Optimizing Airflow with Advanced Honeycomb Ventilation SolutionsNewsJun.10,2025

-

Optimizing Airflow and Testing Efficiency with Honeycomb TechnologyNewsJun.10,2025

-

Enhanced Turbine Efficiency with Sealed Honeycomb TechnologyNewsJun.10,2025

-

Engineering Excellence with Steel Honeycomb Core StructuresNewsJun.10,2025