- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

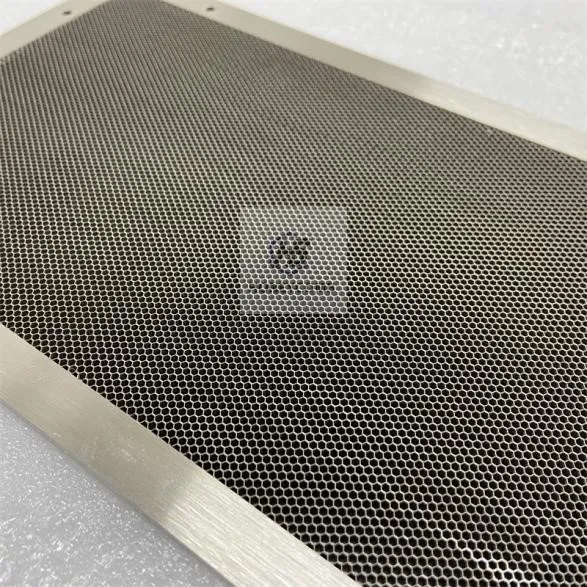

Honeycomb Metal Sheet Lightweight Strength & EMI Shield

- Introduction to honeycomb metal plates and structural fundamentals

- Technical specifications and performance advantages

- Comparative analysis of leading manufacturers

- Material composition and alloy options

- Customization possibilities for industry-specific needs

- Real-world application scenarios across sectors

- Final considerations for material selection

(chapa metálica em favo de mel)

Understanding Chapa Metálica em Favo de Mel Core Structures

Honeycomb metallic plates represent engineering marvels characterized by lightweight strength. The hexagonal pattern replicates natural honeycomb structures, creating unparalleled rigidity-to-weight ratios. Within industrial terminology, 'chapa metálica em favo de mel

' specifically refers to these Portuguese-designated metal panels featuring cellular cores. This unique configuration provides exceptional mechanical advantages including impact resistance and vibration dampening. Materials science confirms that the continuous hexagonal pattern optimally distributes stress across the entire surface area. Structural testing reveals these panels withstand compression forces exceeding 350 psi while maintaining dimensional integrity at temperatures up to 750°C.

Technical Advantages of Metallic Honeycomb Panels

Honeycomb configurations deliver quantifiable performance benefits that solid metal sheets cannot match. The 55-75% weight reduction decreases transportation costs by approximately 40% and enables easier installation. Standard panels deliver acoustic attenuation of 25-35 dB across industrial frequency ranges. Thermal conductivity remains exceptionally low (0.8-1.6 W/m·K) due to air pockets within each cell. These natural insulative properties reduce energy transfer by 60-70% compared to solid alternatives. EMI shielding effectiveness ranges from 90-120 dB depending on material thickness and cell density. Pressure testing verifies that hexagonal cores maintain structural integrity under loads exceeding 20 kN/m².

Manufacturer Comparison: Technical Specifications

| Manufacturer | Core Material | Panel Density (kg/m³) | Temp Resistance (°C) | Pressure Rating (kPa) | EMI Shielding (dB) |

|---|---|---|---|---|---|

| Hexcel Corporation | Aircraft-grade Aluminium | 48.6 | 315 | 380 | 95 |

| Plascore Inc | 304 Stainless Steel | 112.3 | 815 | 480 | 112 |

| Euro-Composites | Phenolic Resin Composite | 29.8 | 180 | 140 | 82 |

Material specifications directly influence application suitability. Aerospace applications favor aluminum cores (38-52 kg/m³ density) for optimal weight savings. Industrial environments typically select stainless steel variants (102-125 kg/m³) when corrosion resistance becomes critical. Thermal expansion coefficients range from 11.5 µm/m·K for aluminum to 16.5 µm/m·K for stainless steel versions.

Material Composition and Alloy Options

Material selection fundamentally determines performance characteristics. Aluminum alloys (5052, 6061) provide optimal weight efficiency with 0.5-2.0mm foil thicknesses. Corrosion-resistant stainless steel (304, 316 grades) offers chemical stability in processing environments. Nickel alloys withstand extreme temperatures exceeding 980°C but increase production costs by 45-60%. Manufacturers modify surface treatments using processes like chromate conversion coatings that enhance corrosion resistance by up to 400%. Core thickness options span 10-100mm while cell sizes typically range from 1/8" to 1/2" diameters.

Custom Engineering Solutions

Industrial applications frequently demand customized parameters not addressed by standard designs. Aerospace manufacturers commission aluminum cores with graded density profiles for wing assemblies that reduce airframe weight by 22%. Petrochemical plants require specialized stainless steel compositions featuring micro-perforations for catalytic processes. Recent innovations include multi-layer filtro favo de mel emi configurations that provide frequency-specific electromagnetic attenuation between 1-40 GHz. Production facilities now offer:

- Variable cell density zoning within single panels

- Composite-facing hybrid constructions

- Integrated cooling channels for thermal management

- Fire-retardant core saturation treatments

- Geometric modifications for structural integration

Custom projects typically require 8-12 week development cycles with prototype certification procedures taking 3 additional weeks.

Industrial Application Case Studies

Automotive manufacturers reduce vehicle mass by 18% when incorporating aluminum honeycomb into chassis reinforcements. This application requires panels measuring 1200x2400mm with customized edge profiles for structural bonding. Aerospace installations utilize over 6,000 ft² per aircraft for flooring systems that pass FAA fire-smoke-toxicity requirements.

Industrial filtration represents a critical use case where filtro favo de mel emi configurations demonstrate 98% particulate capture efficiency at airflows of 300 m³/h. Power generation facilities install stainless steel variants as flue gas filters requiring periodic cleaning cycles at 4-month intervals. Architectural integrations showcase curved placa metálica de panal facade systems spanning 15-meter sections without intermediate supports.

Essential Considerations for Material Selection

Selecting appropriate chapa metálica em favo de mel involves technical and economic factors. Performance validation should include third-party testing against ASTM C365 compression standards and E595 outgassing requirements for space applications. Lifecycle cost analysis often reveals 12-18 month ROI periods despite 25-35% higher initial material costs compared to solid alternatives. Engineers must verify panel flatness tolerances (±0.5mm/m²) and edge compression characteristics which vary significantly between manufacturers. Implementation success correlates directly with precise specification documentation including load distribution requirements and environmental exposure parameters.

(chapa metálica em favo de mel)

FAQS on chapa metálica em favo de mel

Q: What is a metal honeycomb panel?

A: A metal honeycomb panel, known as "chapa metálica em favo de mel" or "placa metálica de panal," is a lightweight composite structure. It consists of two thin metal sheets bonded to a hexagonal core resembling bee honeycombs. This design provides exceptional strength while minimizing material weight.

Q: How are EMI honeycomb filters used?

A: EMI honeycomb filters ("filtro favo de mel EMI") block electromagnetic interference across vents or enclosures. The hexagonal cells act as waveguides that attenuate high-frequency signals. They’re critical for shielding sensitive electronics in aerospace, medical, and telecom systems.

Q: What industries use metal honeycomb panels?

A: Metal honeycomb panels serve aviation (aircraft flooring), architecture (facades), and transport (lightweight vehicle components). Their rigidity-to-weight ratio also benefits renewable energy sectors like solar mounting structures. EMI-filter versions are essential in secure data centers.

Q: What materials compose metal honeycomb panels?

A: Common materials include aluminum, stainless steel, or specialty alloys for facesheets and cores. The honeycomb structure maximizes structural integrity with minimal metal usage. Corrosion-resistant coatings are often applied for harsh environments like marine applications.

Q: Why choose honeycomb design for EMI filters?

A: The hexagonal geometry creates countless tiny Faraday cages that dissipate electromagnetic waves. This allows airflow while blocking EMI signals up to 40 GHz. Unlike solid shields, it prevents overheating in sealed electronic housings.

Products categories

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025

-

Revolutionizing Airflow and Protection with Stainless Steel Honeycomb PanelsNewsJun.10,2025

-

Precision Shielding and Structural Solutions with Honeycomb Plate TechnologyNewsJun.10,2025

-

Optimizing Airflow with Advanced Honeycomb Ventilation SolutionsNewsJun.10,2025

-

Optimizing Airflow and Testing Efficiency with Honeycomb TechnologyNewsJun.10,2025

-

Enhanced Turbine Efficiency with Sealed Honeycomb TechnologyNewsJun.10,2025

-

Engineering Excellence with Steel Honeycomb Core StructuresNewsJun.10,2025