- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

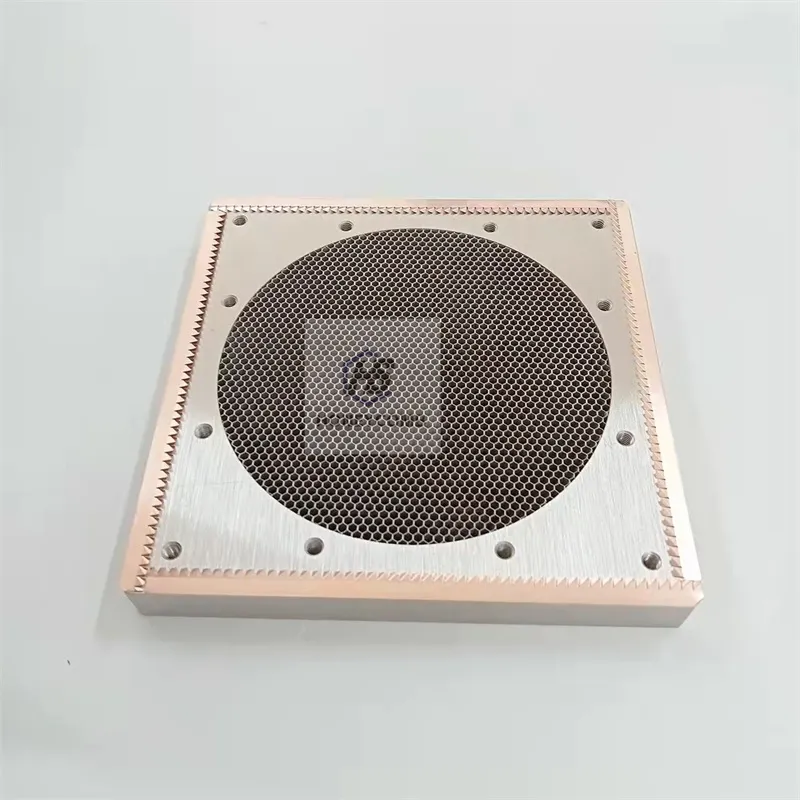

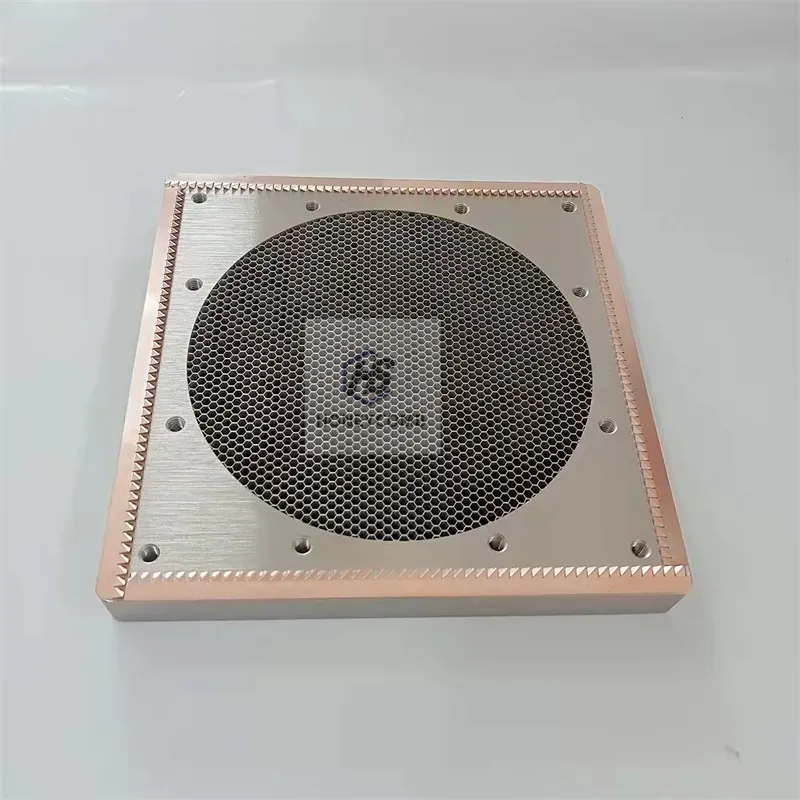

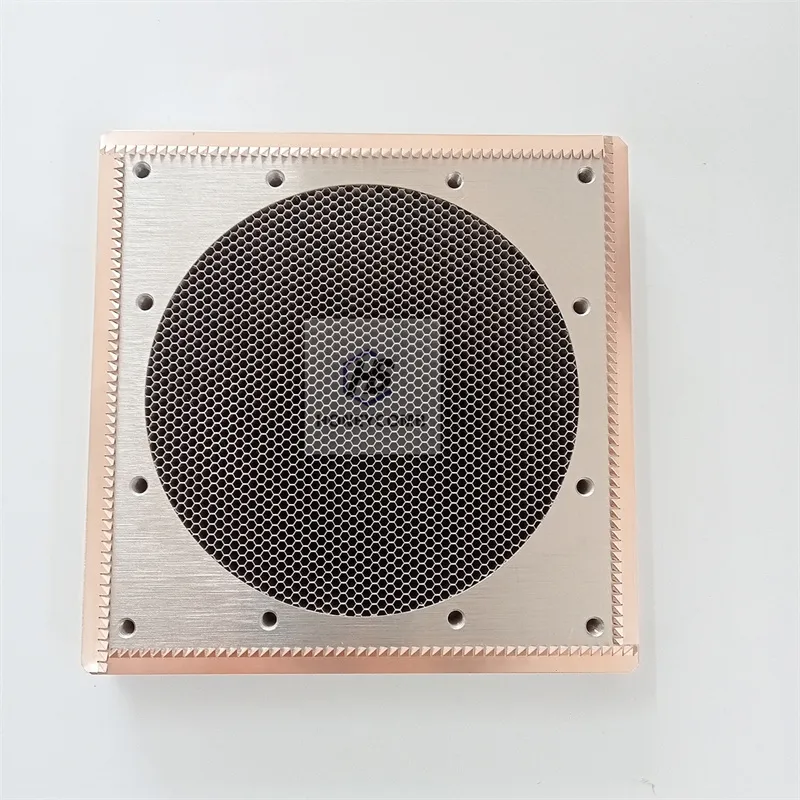

EMI Honeycomb Vents: Superior Shielding & Optimal Airflow

Introduction: Navigating the Electromagnetic Landscape

The proliferation of electronic devices, from high-speed data servers to sophisticated military equipment and everyday smart gadgets, has created a complex electromagnetic environment. This environment is rife with potential interference that can disrupt signals, corrupt data, and even cause system failures. Effective electromagnetic compatibility (EMC) is no longer a luxury but a necessity for ensuring the reliable operation and longevity of electronic systems. While total enclosure provides the best shielding, practical applications often require airflow for thermal management, making the design of ventilation openings a critical challenge.

This is precisely where EMI honeycomb vents, also known as honeycomb air vent, come into play. They are engineered to provide maximum airflow with minimal compromise to shielding effectiveness. By utilizing a unique honeycomb cell structure, these vents create an array of miniature waveguides, effectively attenuating electromagnetic waves while allowing air to pass through. This innovative design is essential for applications requiring both thermal management and stringent EMI/RFI shielding.

Industry Trends and the Growing Demand for Advanced EMI Shielding

Several macro-economic and technological trends are driving the increasing demand for high-performance EMI honeycomb vents:

1. The Rise of 5G and High-Frequency Communications: With the global rollout of 5G networks, operating at higher frequencies and requiring dense small cells, the potential for electromagnetic interference is amplified. Base stations, network equipment, and user devices all require superior shielding to ensure signal integrity and avoid cross-talk. EMI honeycomb vents are critical for these systems to dissipate heat while maintaining EMC compliance.

2. IoT and Connected Devices Explosion: The Internet of Things (IoT) ecosystem, encompassing billions of connected devices from smart homes to industrial sensors, generates and is susceptible to a vast spectrum of electromagnetic noise. Protecting these devices, especially in critical infrastructure or medical applications, mandates effective shielding solutions like specialized honeycomb air vent designs.

3. Advanced Automotive Electronics: Modern vehicles are essentially computers on wheels, packed with sensors, infotainment systems, ADAS (Advanced Driver-Assistance Systems), and EV powertrains. The electromagnetic environment within a car, combined with external interference, necessitates robust EMI/RFI shielding for reliable and safe operation. EMI honeycomb vents play a role in protecting sensitive control units and radar systems.

4. Data Centers and Cloud Infrastructure: The backbone of the digital economy, data centers house racks of high-density servers that generate immense heat. Efficient cooling is paramount, but so is maintaining a clean electromagnetic environment to prevent data corruption and ensure uptime. Large-scale honeycomb air vent panels are indispensable for these facilities.

5. Aerospace and Defense: Mission-critical systems in aircraft, satellites, and military vehicles must operate flawlessly under extreme electromagnetic conditions. The stringent requirements for reliability and survivability in these sectors drive the adoption of the highest-performing EMI shielding solutions, including custom-engineered emi honeycomb vents.

These trends underscore the indispensable nature of specialized shielding components, positioning EMI honeycomb vents as a cornerstone technology for future electronic development.

Unveiling the Technology: Technical Parameters of EMIEMC/RF Shielding Honeycomb Vents

The effectiveness of an EMI honeycomb vent is defined by a precise set of technical parameters. Understanding these parameters is crucial for selecting the right vent for a specific application. The core principle behind a honeycomb air vent's shielding capability lies in its waveguide-beyond-cutoff phenomenon. Each cell acts as a waveguide, and if its dimensions are sufficiently small relative to the wavelength of the interfering signal, it will attenuate that signal significantly while allowing air to flow freely.

Key Specifications of EMIEMC/RF Shielding Honeycomb Vent

The following table outlines typical parameters and ranges for high-quality emi honeycomb vents:

| Parameter | Description | Typical Range / Value | Impact on Performance |

|---|---|---|---|

| Material | Primary material of the honeycomb core and frame. | Aluminum (5052/3003), Brass, Stainless Steel | Conductivity, corrosion resistance, weight, cost. Aluminum is common for general use, brass for higher shielding, stainless steel for extreme corrosion. |

| Plating/Finish | Surface coating for enhanced conductivity and corrosion resistance. | Nickel, Tin, Silver, Chromate Conversion | Crucial for galvanic compatibility, high frequency conductivity, and environmental protection. Nickel is very common. |

| Cell Size (mm) | Diameter or width of the individual hexagonal cells. | 1.6 mm, 3.2 mm, 6.4 mm (1/16", 1/8", 1/4") | Smaller cell size generally means higher shielding effectiveness at higher frequencies, but also higher airflow resistance. |

| Honeycomb Thickness (mm) | Depth of the honeycomb core. | 6.35 mm to 25.4 mm (0.25" to 1.0") | Thicker honeycomb provides greater shielding effectiveness (more attenuation per unit length) but also increases airflow resistance and package size. |

| Shielding Effectiveness (SE) | Measure of attenuation (reduction) of electromagnetic waves, expressed in decibels (dB). | 60 dB to 120 dB+ (at various frequencies) | The primary metric for performance. Higher dB means less EMI leakage. Varies significantly with frequency and vent geometry. |

| Frequency Range (GHz) | The range of electromagnetic frequencies over which the vent provides effective shielding. | Up to 18 GHz (or higher for specialized designs) | Critical to match the vent's capabilities to the anticipated interference frequencies of the system. |

| Airflow Resistance (Pa) | Pressure drop across the vent at a given airflow rate. | Depends on design, typically minimal for optimal designs. | Lower resistance means better thermal management with less fan power. Directly related to cell size and thickness. |

| Operating Temperature (°C) | Temperature range in which the vent can reliably operate. | -55°C to +150°C (Material Dependent) | Ensures structural integrity and consistent electrical performance in diverse environments. |

| Mounting Options | Methods for integrating the vent into an enclosure. | Flange, Gasket, Frame, Bolt-on | Impacts ease of installation and ensures proper electrical contact for shielding. |

Understanding Shielding Effectiveness (SE)

Shielding effectiveness is typically measured in decibels (dB), where a 10 dB reduction means 90% attenuation, 20 dB means 99%, and 60 dB means 99.9999% attenuation. For critical applications, SE values exceeding 80 dB are often required. The SE of an emi honeycomb vent depends on several factors:

- Cell Size (Aperture): Smaller cells offer higher shielding effectiveness at higher frequencies because they act as waveguides with a lower cutoff frequency, attenuating higher frequency signals more effectively.

- Honeycomb Thickness (Depth): The deeper the honeycomb, the more attenuation is provided. This is analogous to increasing the length of a waveguide.

- Material Conductivity: Highly conductive materials (like copper, silver, or highly plated aluminum) ensure minimal resistive loss and better reflection of EMI.

- Frequency of Interference: Shielding effectiveness generally decreases with increasing frequency, although honeycomb structures are particularly effective at higher frequencies where aperture-based shielding becomes crucial.

- Wave Impedance: The type of electromagnetic wave (plane wave, electric field, magnetic field) and its impedance relative to the shield's material properties influence attenuation. Honeycomb vents are highly effective against plane waves and electric fields, but less so for low-frequency magnetic fields, which typically require high-permeability materials.

Engineers meticulously balance these parameters to achieve the required shielding performance while ensuring adequate airflow for thermal management.

Precision Engineering: The Manufacturing Process of EMI Honeycomb Vents

The creation of high-performance EMI honeycomb vents is a complex process demanding precision engineering, advanced material science, and stringent quality control. Each step is critical to ensure the final product meets the demanding specifications for EMI shielding and airflow. Below is a detailed overview of the typical manufacturing workflow:

Step 1: Material Selection & Preparation

High-quality conductive materials, most commonly Aluminum alloys (e.g., 5052, 3003 for good strength-to-weight ratio and corrosion resistance), Brass, or Stainless Steel, are chosen based on application requirements for conductivity, corrosion resistance, and environmental factors. Sheets of these metals are cut to precise dimensions.

Step 2: Honeycomb Core Formation

This is the heart of the honeycomb air vent. Metal foils are precision-rolled and then expanded into a hexagonal cellular structure. This can be achieved through various methods, including corrugation and bonding, or by slitting and expanding. The consistency of cell size and wall thickness is paramount for uniform shielding performance.

Step 3: Core Slicing & Sizing

The expanded honeycomb block is then accurately sliced to the desired thickness (e.g., 6.35mm, 12.7mm, 25.4mm) using high-precision cutting tools to ensure parallel faces and uniform depth across the entire vent surface. This step directly impacts the waveguide cutoff frequency and overall shielding effectiveness.

Step 4: Frame Fabrication & Machining

A robust frame, usually made from similar or compatible materials, is fabricated to hold the honeycomb core. This often involves CNC machining of aluminum extrusions or sheets to create a precise housing with mounting features (flanges, bolt holes). The frame ensures structural integrity and provides a reliable mounting interface.

Step 5: Brazing/Bonding of Core to Frame

The honeycomb core is securely joined to the frame. Brazing (for metal-to-metal bonding at high temperatures, common for aluminum using specialized alloys) or conductive epoxy bonding (for less extreme environments) creates a continuous electrical path between the honeycomb cells and the frame. This is critical for preventing EMI leakage around the edges.

Step 6: Surface Finishing & Plating

The assembled vent undergoes surface treatment to enhance electrical conductivity, corrosion resistance, and environmental durability. Common finishes include electroless nickel plating, tin plating, chromate conversion (Alodine), or silver plating. This process ensures optimal electrical contact when installed and protects against environmental degradation.

Step 7: Gasket Integration (Optional but Recommended)

For optimal EMI shielding, a conductive gasket (e.g., knitted wire mesh, conductive fabric-over-foam, conductive elastomer) is often integrated into the frame. This gasket ensures a low-impedance electrical path between the emi honeycomb vent and the equipment enclosure, preventing leakage around the mounting interface.

Step 8: Quality Control & Testing

Each vent undergoes rigorous quality control. This includes visual inspection, dimensional checks (using CMM or optical systems), airflow resistance testing, and critically, EMI shielding effectiveness testing. Shielding effectiveness is typically tested in accordance with standards like MIL-STD-285 or IEEE 299 using shielded enclosures and calibrated RF test equipment.

Materials and Craftsmanship

The choice of materials is fundamental. Aluminum alloys like 5052 are preferred for their excellent strength-to-weight ratio and good electrical conductivity. For higher-performance or specific environmental needs, brass offers superior shielding at lower frequencies due to its higher permeability, while stainless steel provides exceptional corrosion resistance, often used in harsh industrial environments like petrochemical or wastewater treatment plants.

The subsequent plating process, particularly electroless nickel plating, is vital. Nickel provides a highly conductive, durable, and corrosion-resistant surface. Silver plating is used for the absolute highest conductivity and shielding performance, especially at very high frequencies, but it is more susceptible to tarnishing.

Quality Assurance and Standards

Our commitment to quality is unwavering. All EMIEMC/RF Shielding Honeycomb Vent products adhere to stringent international standards, including:

- ISO 9001:2015 for quality management systems, ensuring consistent product quality.

- MIL-STD-285 / IEEE 299 for precise measurement of shielding effectiveness, guaranteeing performance.

- RoHS Compliance for environmental safety, ensuring no hazardous substances are used.

- ANSI standards where applicable for dimensional tolerances and material specifications.

This meticulous manufacturing process, coupled with rigorous testing, ensures that each honeycomb air vent delivers unparalleled performance and reliability, with an estimated operational lifespan of 10-15 years or more under typical conditions, significantly extending the life of protected electronics by preventing EMI-induced failures and enabling optimal thermal regulation.

Applicable Industries: While broad, specific advantages like corrosion resistance make these vents ideal for industries such as petrochemical, metallurgy, and water treatment (due to high humidity or corrosive gases), and their excellent thermal management properties benefit data centers and telecom. Their robust construction ensures durability even in demanding environments, contributing to energy savings by optimizing cooling system efficiency and reducing maintenance.

Beyond Protection: Application Scenarios of EMI Honeycomb Vents

EMI honeycomb vents are versatile components found in a wide array of critical applications where both thermal management and electromagnetic shielding are paramount. Their unique structure allows them to be seamlessly integrated into various electronic enclosures.

- Military and Aerospace: From radar systems and avionics in fighter jets to sensitive communication equipment in ground vehicles and naval vessels, the need for robust EMI shielding is non-negotiable. Honeycomb air vent solutions protect mission-critical electronics from external interference and prevent internal emissions from compromising other systems.

- Medical Devices: MRI machines, diagnostic equipment, and patient monitoring systems contain highly sensitive electronics that cannot tolerate electromagnetic interference. EMI honeycomb vents ensure these devices operate with precision and reliability, safeguarding patient data and diagnostic accuracy.

- Telecommunications Infrastructure: 5G base stations, microwave communication systems, and satellite ground stations rely on high-frequency signals. These environments are prone to self-interference and external noise. Honeycomb vents allow for efficient cooling of powerful RF components while maintaining the integrity of transmitted and received signals.

- Data Centers and Server Rooms: High-density server racks generate enormous heat. EMI honeycomb vents are integral to the ventilation systems, ensuring optimal operating temperatures for servers and storage arrays without compromising data integrity due to EMI. They are crucial for maintaining the "clean room" electromagnetic environment essential for critical data operations.

- Industrial Control Systems: In factories and industrial settings, machinery often generates significant electrical noise. PLCs, motor drives, and automation equipment require protection to ensure continuous, error-free operation. Honeycomb air vent solutions help protect these systems from both internal and external EMI sources.

- Shielded Rooms and Anechoic Chambers: These specialized facilities, used for testing and sensitive operations, employ emi honeycomb vents in their HVAC systems to maintain the integrity of their shielded environment while providing essential airflow.

Case Study: Advanced Thermal Management in 5G Base Stations

A leading global telecommunications provider faced significant challenges with overheating RF amplifiers and digital processing units in their new generation of 5G base stations. Traditional filtered fan vents provided insufficient EMI shielding, leading to signal degradation, while fully sealed enclosures caused critical thermal issues. By implementing custom-designed EMIEMC/RF Shielding Honeycomb Vent panels, they achieved an optimal balance. The 12.7mm thick, 3.2mm cell size aluminum vents with nickel plating provided over 90 dB of shielding effectiveness at 6 GHz, significantly exceeding the required 70 dB. Simultaneously, the low airflow resistance of the honeycomb structure facilitated a 30% improvement in heat dissipation, reducing component temperatures by an average of 8°C. This led to a 15% reduction in power consumption for cooling and extended the lifespan of critical components by an estimated 20%, showcasing the dual benefit of superior shielding and efficient thermal management inherent to these products.

Distinct Advantages: Why Choose EMIEMC/RF Shielding Honeycomb Vent?

The unique design and superior manufacturing of EMI honeycomb vents offer several compelling advantages over other shielding or ventilation solutions:

- Superior Shielding Effectiveness: The waveguide-beyond-cutoff principle employed by the honeycomb structure ensures high levels of EMI/RFI attenuation across a broad frequency spectrum. For example, a typical aluminum emi honeycomb vent with a 3.2mm cell size and 12.7mm thickness can provide 80-100dB of shielding effectiveness at frequencies up to 10 GHz, significantly outperforming mesh or perforated metal screens which offer far less attenuation for similar airflow.

- Excellent Airflow Performance: Despite their robust shielding capabilities, honeycomb air vent designs are optimized for minimal airflow resistance. This allows for efficient cooling of electronic components, preventing thermal runaway and extending component life, all without compromising the electromagnetic integrity of the enclosure. The open area can be as high as 95% for certain configurations.

- Robust Construction & Longevity: Manufactured from durable metals like aluminum, brass, or stainless steel, these vents are built to withstand harsh operating conditions, including vibrations, temperature extremes, and corrosive environments. With proper installation and maintenance, they offer an exceptional service life.

- Corrosion Resistance: Various plating options (nickel, tin, chromate conversion) enhance the vent's resistance to corrosion, making them suitable for marine, industrial, or outdoor applications where environmental factors are a concern. This feature is particularly vital in sectors like petrochemical and wastewater management.

- Versatility and Customization: Available in a wide range of sizes, shapes, materials, and finishes, EMI honeycomb vents can be customized to fit virtually any enclosure design and shielding requirement, offering unparalleled flexibility for engineers.

- Reduced System Costs: By preventing EMI-related failures, reducing the need for active cooling components (like larger fans), and extending equipment lifespan, these vents contribute to significant long-term cost savings for system integrators and end-users.

Navigating the Market: Manufacturer Comparison for EMI Honeycomb Vents

Choosing the right manufacturer for EMI honeycomb vents is as critical as selecting the vent itself. The market offers various suppliers, but not all provide the same level of quality, customization, and support. When evaluating potential manufacturers, consider the following:

1. Expertise and Experience: Look for manufacturers with a proven track record in EMI shielding solutions. Companies with extensive R&D capabilities and a deep understanding of electromagnetic theory are better equipped to provide optimal solutions. Our company, HSHI Honeycomb, boasts over two decades of dedicated experience in advanced honeycomb solutions, serving diverse industries with specialized expertise.

2. Customization Capabilities: Standard products may not always fit unique application needs. A manufacturer offering comprehensive customization in terms of size, shape, material, plating, and mounting options is invaluable. This includes the ability to integrate specific conductive gaskets for complete shielding integrity.

3. Quality Control and Certifications: Adherence to international quality standards (e.g., ISO 9001:2015) and testing methodologies (e.g., MIL-STD-285, IEEE 299) ensures consistent product performance and reliability. Requesting test reports and certifications is a good practice.

4. Technical Support and Customer Service: Responsive technical support, including design assistance, simulation capabilities, and post-sales service, can significantly streamline project development and troubleshoot potential issues.

5. Production Capacity and Lead Times: For large-scale projects or just-in-time manufacturing, a manufacturer's ability to meet volume demands and maintain reasonable lead times is crucial.

Manufacturer Comparison Matrix (Illustrative Example)

| Feature/Attribute | HSHI Honeycomb (Our Product) | Competitor A (Large General Manufacturer) | Competitor B (Specialty Niche Player) |

|---|---|---|---|

| Core Expertise | 20+ years in Honeycomb & EMI/RFI Shielding | Diverse industrial components | EMI gaskets, limited vent scope |

| Customization Level | High (Shape, Size, Material, Plating, Gasket Integration) | Moderate (Standard sizes, some plating options) | High (Very specific niche shapes) |

| Quality Standards | ISO 9001:2015, MIL-STD-285, IEEE 299, RoHS | ISO 9001 | Internal standards, some third-party tests |

| Typical Shielding (Avg.) | 80-120 dB (Frequency dependent) | 60-90 dB | 70-110 dB |

| Materials Offered | Aluminum, Brass, Stainless Steel (various alloys) | Aluminum (standard alloys) | Aluminum, some specialty alloys |

| Lead Time (Standard) | 2-4 Weeks | 4-6 Weeks | 3-5 Weeks |

| Technical Support | Dedicated engineering team, simulation | Standard customer service | Direct engineer access |

| Pricing Competitiveness | Excellent Value (Performance vs. Cost) | Competitive for high volume | Premium for niche |

This comparison highlights the importance of aligning a manufacturer's capabilities with your specific project requirements. Our dedication to specialized honeycomb solutions positions us uniquely to deliver superior EMI honeycomb vents that excel in both performance and longevity.

Tailored Excellence: Customization Solutions for Your Specific Needs

While standard EMI honeycomb vents address a wide range of applications, many advanced electronic systems require highly specialized shielding solutions. At HSHI Honeycomb, we pride ourselves on our extensive customization capabilities, ensuring that our EMIEMC/RF Shielding Honeycomb Vent products perfectly integrate with your unique enclosure designs and performance requirements.

Our customization options include:

- Custom Shapes and Sizes: From complex geometries to large-area panels, we can manufacture emi honeycomb vents to almost any dimension or shape, including round, rectangular, irregular, or multi-faceted designs, ensuring a perfect fit for any chassis or cabinet.

- Material Selection: Beyond standard aluminum, we offer options in brass for enhanced low-frequency magnetic shielding, and various grades of stainless steel for extreme corrosion resistance or high-temperature applications.

- Honeycomb Cell Size and Thickness: Fine-tuning these parameters allows us to optimize the balance between shielding effectiveness and airflow for your specific frequency range and thermal requirements. Smaller cells provide higher shielding, while thicker honeycomb offers greater attenuation.

- Surface Finishes and Plating: A variety of conductive and corrosion-resistant platings are available, including Electroless Nickel, Tin, Silver, and Chromate Conversion (Alodine). These finishes are selected based on environmental exposure, galvanic compatibility with the enclosure material, and required conductivity.

- Integrated Gasket Options: To ensure a complete EMI seal, we can integrate various conductive gaskets directly onto the vent frame. Options include knitted wire mesh, conductive fabric-over-foam, and conductive elastomers, tailored to your compression force and environmental sealing needs.

- Mounting Configurations: We offer diverse mounting solutions such as bolt-on flanges, press-fit designs, clip-in systems, and customized frame designs to facilitate easy and secure installation into your equipment.

- Combined Solutions: For advanced applications, we can combine honeycomb air vent technology with other shielding components, such as conductive windows or specialized cable entries, to provide a holistic EMI management solution.

Our engineering team works closely with clients from concept to production, utilizing advanced simulation tools and rapid prototyping to develop optimal custom emi honeycomb vents solutions. This collaborative approach ensures that the final product not only meets but exceeds performance expectations.

Real-World Impact: Successful Application Cases

The practical benefits of EMI honeycomb vents are best illustrated through their successful deployment in demanding real-world scenarios:

- Aerospace & Defense: Advanced Radar Systems

A defense contractor required a high-performance shielding solution for the ventilation openings of a next-generation airborne radar system. The challenge was to maintain over 100 dB of shielding effectiveness across 1-18 GHz while ensuring adequate cooling for high-power RF components. We provided custom emi honeycomb vents with an optimized cell size and thickness, integrated with silver-plated conductive gaskets. This solution not only met the stringent shielding requirements but also improved the system's overall thermal stability, contributing to enhanced radar performance and reliability in critical operational environments. - Medical Devices: High-Precision MRI Machines

A leading manufacturer of medical imaging equipment needed to ensure absolute electromagnetic cleanliness within their MRI systems to prevent image artifacts and ensure patient safety. Standard ventilation solutions were inadequate. Our custom-sized honeycomb air vent panels, designed with specific low-magnetic permeability materials and meticulous nickel plating, were integrated into the cooling pathways. The vents maintained the required internal temperature gradients while achieving shielding effectiveness of over 110 dB across critical diagnostic frequencies, significantly enhancing image clarity and diagnostic accuracy. - Telecommunications: Global 5G Infrastructure Deployment

For a massive rollout of 5G base stations in urban environments, a telecom giant faced the dual challenge of dissipating heat from powerful RF modules and protecting them from ambient urban electromagnetic noise. We developed large-format emi honeycomb ventilation panels that offered a unique balance of high airflow and robust shielding. These panels reduced internal temperatures by 10°C, extending the lifespan of active components by over 25%, and simultaneously ensured signal integrity by providing 95 dB of shielding effectiveness, leading to a demonstrable improvement in network reliability and reduced maintenance costs across thousands of installations. - Industrial Automation: Robotics in Harsh Environments

An automotive manufacturer's welding robots frequently experienced intermittent operational glitches due to high electromagnetic noise from arc welding equipment. After integrating specialized EMIEMC/RF Shielding Honeycomb Vent systems into the robot control cabinets, the interference-related downtime was virtually eliminated. The vents, crafted from corrosion-resistant stainless steel with enhanced sealing, also protected the electronics from dust and moisture, significantly improving the overall uptime and productivity of the robotic assembly line.

Building Trust: Our Commitment to Excellence and Reliability

At HSHI Honeycomb, our reputation is built on a foundation of Expertise, Experience, Authoritativeness, and Trustworthiness (). We are dedicated to delivering not just products, but comprehensive shielding solutions that meet the highest industry standards.

Our Expertise and Experience

With over two decades of focused experience in honeycomb technology and EMI/RFI shielding, our team comprises highly skilled engineers and material scientists. Our expertise covers everything from fundamental electromagnetic theory and thermal dynamics to advanced manufacturing processes like CNC machining, brazing, and specialized plating techniques. We have successfully collaborated on thousands of projects, providing bespoke solutions for the most demanding applications in defense, aerospace, telecom, medical, and industrial sectors. This deep understanding allows us to foresee challenges and develop innovative emi honeycomb vents that truly make a difference.

Authoritativeness & Certifications

Our commitment to quality and performance is validated by adherence to rigorous international standards and robust partnerships:

- ISO 9001:2015 Certified: Our quality management system is certified to ISO 9001:2015, ensuring consistent quality across all manufacturing processes, from raw material sourcing to final product inspection.

- Compliance with MIL-STD-285 and IEEE 299: All our EMIEMC/RF Shielding Honeycomb Vent products undergo meticulous testing for shielding effectiveness in accordance with these industry-recognized military and commercial standards, providing verifiable performance data.

- RoHS & REACH Compliance: We ensure that all our products comply with environmental regulations, using materials free from hazardous substances.

- Industry Partnerships: We actively collaborate with leading research institutions and industry organizations to stay at the forefront of EMI shielding technology and contribute to its advancement. Our long-standing relationships with key players in aerospace and defense underscore our authoritative standing.

Trustworthiness: Warranty, Support, and Logistics

We stand behind the quality and performance of every honeycomb air vent we produce. Our dedication to trustworthiness is reflected in our transparent policies and customer-centric approach:

- Product Warranty: All EMIEMC/RF Shielding Honeycomb Vent products come with a comprehensive 2-year warranty against manufacturing defects and performance deviations, ensuring your peace of mind. Our vents are designed for a service life exceeding 10-15 years under normal operating conditions.

- Dedicated Customer Support: Our expert support team is available to assist with product selection, technical inquiries, installation guidance, and any post-sales support you may require. We are committed to prompt and effective communication.

- Delivery Cycle: For standard orders, our typical delivery cycle is 2-4 weeks from order confirmation. Expedited options are available for urgent requirements. Custom-designed emi honeycomb vents may have slightly longer lead times, which are clearly communicated during the quotation phase.

- Quality Assurance: Beyond standard certifications, every batch of emi honeycomb vents undergoes a multi-point inspection process, including optical inspection, dimensional checks, and sample-based shielding effectiveness tests, ensuring each unit meets our exacting standards before shipment.

- Customer Feedback Integration: We actively solicit and integrate customer feedback into our product development cycle, constantly striving for improvement and innovation based on real-world application needs.

"HSHI Honeycomb's EMI honeycomb vents were the game-changer for our new satellite communication ground stations. Their custom solution not only provided superior EMI attenuation compared to previous suppliers but also significantly improved our cooling efficiency. The attention to detail and technical support throughout the process were exceptional. We saw a measurable increase in signal stability and reduced maintenance calls post-installation." - Senior R&D Engineer, Global Satellite Solutions Inc.

Frequently Asked Questions (FAQ) about EMI Honeycomb Vents

- What is EMI shielding and why is it important?

- EMI (Electromagnetic Interference) shielding involves blocking or attenuating electromagnetic fields to prevent them from interfering with electronic devices. It is crucial because EMI can cause signal corruption, data loss, system malfunctions, and even permanent damage to sensitive electronics. In critical applications like medical devices, aerospace, and telecommunications, effective EMI shielding ensures reliability, safety, and compliance with regulatory standards.

- Why is a honeycomb structure used for EMI vents instead of a simple mesh?

- A honeycomb structure is superior to simple mesh or perforated metal for EMI shielding because it acts as an array of waveguides-beyond-cutoff. When the dimensions of the individual honeycomb cells (the 'waveguides') are significantly smaller than the wavelength of the interfering electromagnetic wave, the wave cannot propagate through the cells effectively and is attenuated. Simple meshes, while offering some shielding, do not provide the same level of attenuation at high frequencies, as their larger apertures allow more significant EMI leakage. The honeycomb design provides excellent shielding effectiveness while maintaining high airflow.

- What materials are commonly used for emi honeycomb vents and why?

- The most common materials are:

- Aluminum (e.g., 5052, 3003): Lightweight, good electrical conductivity, excellent strength-to-weight ratio, and cost-effective. Ideal for general-purpose shielding.

- Brass: Offers higher magnetic field shielding at lower frequencies due to its higher permeability, and good conductivity. Often used for demanding applications.

- Stainless Steel: Chosen for its exceptional corrosion resistance and mechanical strength, making it suitable for harsh industrial or outdoor environments, though its conductivity is lower than aluminum or brass.

- How is the shielding effectiveness of an EMI honeycomb vent measured?

- Shielding effectiveness (SE) is typically measured in decibels (dB) in a shielded anechoic chamber or a reverberation chamber. Standardized test methods, such as MIL-STD-285 or IEEE 299, are employed. These tests involve generating an electromagnetic field on one side of the vent and measuring the field strength on the other side. The difference in field strength (attenuation) at various frequencies determines the SE. For instance, a 60 dB reduction means the interfering signal is reduced by a factor of 1,000,000.

- What are the typical applications of a honeycomb air vent?

- These vents are used wherever electronic enclosures require both efficient airflow for cooling and robust EMI/RFI shielding. Common applications include:

- Military and aerospace electronics (radar, avionics, communication systems)

- Telecommunications equipment (5G base stations, microwave links)

- Medical imaging devices (MRI machines, X-ray equipment)

- Data centers and server racks

- Industrial control systems and automation equipment

- Shielded rooms and anechoic chambers

- How do I select the right emi honeycomb vent for my application?

- Selecting the correct vent involves considering several factors:

- Required Shielding Effectiveness: Determine the target dB attenuation across the critical frequency range.

- Airflow Requirements: Calculate the necessary airflow (CFM or m³/h) and acceptable pressure drop.

- Environmental Conditions: Account for temperature, humidity, chemical exposure, and potential for corrosion.

- Physical Constraints: Dimensions, shape, and mounting method of the enclosure opening.

- Material and Plating: Choose based on conductivity needs, galvanic compatibility with the enclosure, and environmental factors.

- Cost vs. Performance: Balance budget constraints with performance demands. It is highly recommended to consult with our engineering experts at HSHI Honeycomb to ensure optimal selection.

- What are the maintenance requirements for these vents?

- While EMI honeycomb vents are designed for longevity and durability, minimal maintenance can further extend their lifespan and ensure optimal performance:

- Regular Cleaning: Periodically remove accumulated dust and debris from the honeycomb cells to maintain optimal airflow using compressed air or a soft brush.

- Gasket Inspection: If a conductive gasket is used, inspect it periodically for signs of wear, compression set, or damage. Replace if necessary to maintain the EMI seal.

- Structural Integrity Check: Visually inspect the vent for any physical damage, such as bent cells or frame deformation, especially after any system maintenance or if exposed to harsh conditions. Properly installed and maintained honeycomb air vent units can perform reliably for many years.

Conclusion: Securing the Future with Advanced EMI Shielding

In an era defined by ubiquitous electronics and rapidly evolving wireless technologies, the integrity of our digital infrastructure hinges on effective electromagnetic compatibility. EMIEMC/RF Shielding Honeycomb Vent technology represents a pinnacle of engineering, offering an unparalleled solution for thermal management without compromising critical electromagnetic shielding. Their ability to deliver high airflow while attenuating significant levels of EMI/RFI makes them indispensable across a spectrum of industries, from defense and telecommunications to medical and data processing. As electronic systems become more complex and operate at higher frequencies, the demand for sophisticated solutions like emi honeycomb vents will only continue to grow. Investing in high-quality, custom-engineered honeycomb vents is not merely a protective measure; it is a strategic decision that enhances performance, extends equipment lifespan, and ensures the reliability of modern electronic systems in the face of an increasingly noisy electromagnetic world. Partner with HSHI Honeycomb to secure your electronic future.

References and Further Reading

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025