- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

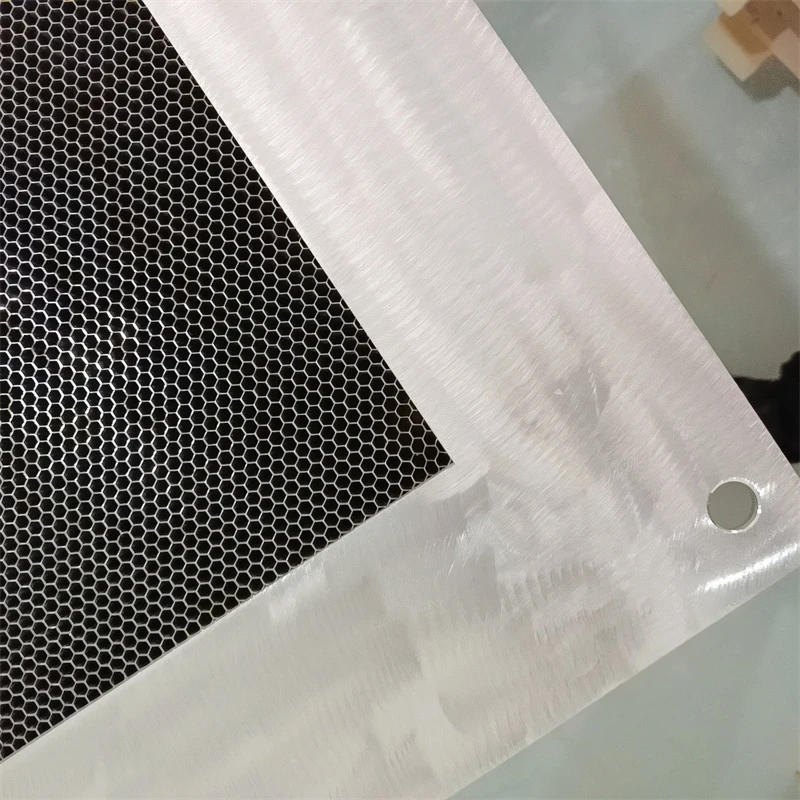

Honeycomb Stainless Steel Sheet Durable & Lightweight

- Exploring the foundational benefits and structural properties of stainless steel honeycomb sheets

- Market growth metrics demonstrating sector-wide adoption and demand surge

- Core technical advantages enabling superior performance in demanding environments

- Comparative analysis of global manufacturers on technical specifications and quality benchmarks

- Flexible customization processes accommodating specialized architectural and industrial requirements

- Diverse implementation scenarios showcasing real-world functional versatility

- Sustainable innovations shaping future applications across industries

(tôle en nid d'abeille en acier inoxydable)

Understanding the Significance of Stainless Steel Honeycomb Sheets

Stainless steel honeycomb panels represent a pinnacle of modern engineering synergy. Combining Grade 304 or 316 alloy cores with precision-welded cell structures, these panels achieve unparalleled strength-to-weight ratios at approximately 90% reduced density compared to solid metal equivalents. The hexagonal configuration mimics natural load-bearing principles found in beehives, distributing stress uniformly while maintaining dimensional stability under extreme temperatures ranging from -200°C to 500°C. This structural intelligence makes honeycomb-structured steel sheets indispensable across aerospace, marine, and architectural applications where material efficiency directly impacts project viability. Surface adhesion capabilities further permit custom cladding treatments including anti-slip, powder-coated, or mirrored finishes for specialized functionality.

Industry Growth Metrics and Material Performance Data

The global honeycomb panel market has demonstrated remarkable 7.8% CAGR since 2018, projected to exceed $6.2 billion by 2028 according to material research analysts. In architectural applications, stainless honeycomb systems yield 40-60% weight reduction versus solid aluminum alternatives while increasing load capacity by 15-25% depending on alloy grade. Thermal conductivity tests reveal 18-22% improvement over monolithic sheets, correlating to measurable reductions in HVAC operating costs. Crucially, accelerated corrosion resistance testing shows honeycomb-structured steel maintaining integrity after 1,000+ salt spray hours, outperforming carbon steel equivalents by 300%. These quantifiable advantages drive rapid adoption in infrastructure projects like the Riyadh Metro expansion utilizing 18,000 m² of honeycomb stainless sheets for durable lightweight ceilings.

Technical Superiority in Structural Applications

Unlike conventional steel sheets, honeycomb core configurations fundamentally transform material behavior. The geometric distribution of stress vectors throughout the hexagonal matrix enables the unique characteristic of achieving 7.2 MPa compressive strength at just 8 kg/m² density. Sound absorption metrics show 28dB noise reduction at mid-frequencies – a critical advantage in transportation and industrial settings. Vibration damping performance exceeds monolithic metal by 60% during resonance testing. Electromagnetic shielding effectiveness registers at 85-110dB from 1 MHz to 10 GHz frequencies, making honeycomb-structured steel sheets vital for sensitive electronics housings. Such performance characteristics emerge from both alloy selection (typically 304, 321, or 316L stainless variants) and core depth parameters ranging from 3mm decorative applications to 50mm structural cores for blast-resistant facades.

Manufacturer Comparison: Technical Specifications Benchmark

| Manufacturer | Core Depth (mm) | Compressive Strength (MPa) | Thermal Conductivity (W/m·K) | Max Panel Size | Standard Alloys |

|---|---|---|---|---|---|

| Astris Structural | 3-50 | 8.3 | 0.8 | 3000x1500mm | 316L, Duplex 2205 |

| Euro Composites | 5-40 | 7.6 | 1.1 | 2500x1250mm | 304, Titanium |

| Plascore | 4-30 | 6.9 | 1.3 | 4000x2000mm | 321, Aluminum |

| Hexcel Corp | 3-25 | 7.2 | 0.9 | 3200x1800mm | 17-7PH Stainless |

Leading fabricators differentiate capabilities through proprietary bonding techniques impacting joint integrity. The aerospace sector reports 12-18% variance in fatigue resistance between manufacturers when testing cyclic loading at 10⁶ cycles. European fabricators typically employ vacuum brazing creating continuous metallurgical bonds, while US counterparts favor epoxy-film adhesives requiring precise thermal curing protocols.

Customization Methodologies and Precision Engineering

Advanced honeycomb panels undergo intensive computational modeling before fabrication to optimize cellular geometry for application-specific stress points. Parametric design permits variation from standard 6.5mm hexagons to 3-20mm cell dimensions where acoustics or flow dynamics dominate performance criteria. Curved panel radii as tight as 300mm are achievable through specialized hydraulic forming with tolerance profiles maintained within ±0.75mm/m. Surface finishing selections extend beyond standard brushed stainless to include perforation patterns achieving 5-70% open area for filtration or ventilation functions. At Singapore's Jewel Changi Airport, bespoke honeycomb-structured steel sheets incorporated integrated LED channels within the core matrix while maintaining just 11.5kg/m² surface density across the 200-meter canopy structure.

Diverse Implementation Scenarios and Sector Applications

The architectural sector accounts for 42% of commercial honeycomb panel deployments, prominently featured in London's Crossrail station facades where 8,000 corrosion-resistant panels withstand urban pollution while providing electromagnetic transparency. Transportation applications include train flooring with honeycomb-structured steel sheets achieving 1-hour fire ratings at 50% weight reduction versus solid plates. Offshore platform applications leverage the material's unique resistance to chloride-induced stress corrosion cracking (CISCC) where standard carbon steel fails within months. Industrial installations demonstrate functionality ranging from cleanroom ceilings in semiconductor fabs to explosion-relief panels in chemical plants. A remarkable pharmaceutical application involves sterilization-autoclavable surgical equipment carts fabricated from nickel-coated honeycomb stainless steel, achieving complete microbial containment through seamless welded edges.

Future Innovations in Stainless Steel Honeycomb Sheet Technology

Emerging research focuses on embedding microchannel functionality within honeycomb cores, potentially transforming thermal management systems. Trials at MIT demonstrated 30% more efficient heat dissipation versus conventional heatsinks through integrated fluidic architecture within stainless steel honeycomb cores. European consortiums are developing phase-change materials (PCM) infused cores capable of thermal energy storage exceeding 200kJ/kg. Graphene-enhanced stainless variants under development promise 40% strength increases while maintaining corrosion resistance. These advancements will expand applications beyond structural roles toward multifunctional smart materials. Near-future architectural projects already specify photovoltaic-integrated honeycomb panels, while automotive prototypes test crash-adaptive structures with variable energy absorption properties. As sustainable construction mandates tighten globally, stainless steel honeycomb sheets stand poised to address contradictory demands for both extreme durability and material efficiency through innovative geometric material science.

(tôle en nid d'abeille en acier inoxydable)

FAQS on tôle en nid d'abeille en acier inoxydable

What is stainless steel honeycomb panel?

Q: What defines a stainless steel honeycomb panel? A: It’s a rigid composite material featuring two parallel stainless steel sheets bonded to a hexagonal aluminum or steel core. This structure creates ultra-lightweight panels with exceptional strength-to-weight ratios. Common alloys like 304 or 316 ensure corrosion resistance in demanding environments.Where are stainless steel honeycomb panels used?

Q: What applications suit stainless steel honeycomb plates? A: They’re ideal for architectural cladding, industrial machinery guards, chemical plant flooring, and transport interiors. Their durability supports high-traffic areas like marine structures or food processing facilities. Decorative uses include avant-garde façades and art installations.Why choose stainless steel over regular steel honeycomb panels?

Q: Why prefer stainless steel over carbon steel honeycomb plates? A: Stainless variants resist rust, acids, and extreme temperatures far better than plain steel counterparts. Grades like 316L offer superior hygiene for sanitary environments. Long-term maintenance costs are lower due to minimal corrosion degradation.How are stainless steel honeycomb panels installed?

Q: What methods install stainless steel honeycomb sheets effectively? A: They’re mounted via adhesive bonding, welding, or mechanical fasteners. Lightweight properties simplify ceiling/suspension systems in construction. Precision cutting ensures seamless joints for curved surfaces or intricate geometries.Can stainless steel honeycomb panels be customized?

Q: Are customization options available for these panels? A: Yes—dimensions (thickness/size), core density, and surface finishes (brushed/mirror/perforated) can be tailored. Special shapes or embossing cater to architectural aesthetics. Electropolishing or PVD coatings enhance durability for specialized industrial needs.Products categories

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025

-

Revolutionizing Airflow and Protection with Stainless Steel Honeycomb PanelsNewsJun.10,2025

-

Precision Shielding and Structural Solutions with Honeycomb Plate TechnologyNewsJun.10,2025

-

Optimizing Airflow with Advanced Honeycomb Ventilation SolutionsNewsJun.10,2025

-

Optimizing Airflow and Testing Efficiency with Honeycomb TechnologyNewsJun.10,2025

-

Enhanced Turbine Efficiency with Sealed Honeycomb TechnologyNewsJun.10,2025

-

Engineering Excellence with Steel Honeycomb Core StructuresNewsJun.10,2025