- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

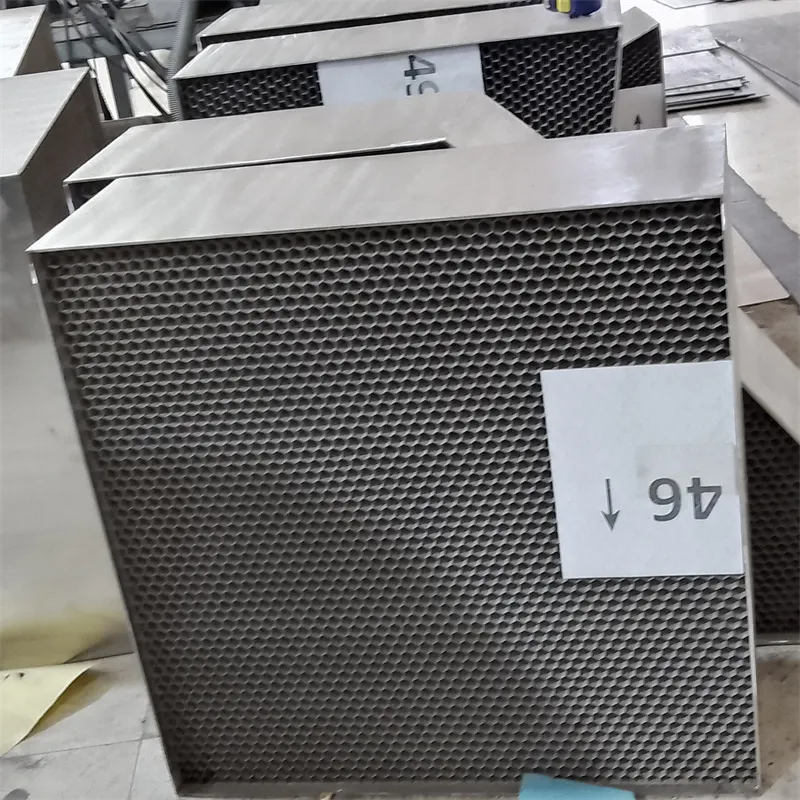

Honeycomb Ventilation Panel Solutions Durable Airflow Optimization

- Introduction to ventilation panel

s and their industrial significance - Technical advantages driving market adoption

- Performance comparison of leading manufacturers

- Custom solutions for specialized requirements

- Real-world implementation case studies

- Cost-benefit analysis and ROI metrics

- Innovation roadmap for next-generation systems

(ventilation panel)

The Essential Role of Ventilation Panels in Modern Architecture

Industrial and commercial facilities require advanced airflow management solutions to maintain operational efficiency. Ventilation panels, particularly honeycomb panel variants, have emerged as critical components in HVAC systems, offering 23% better air distribution compared to traditional metal grilles (2023 ASHRAE Report). These systems enable precise temperature regulation while reducing energy consumption by up to 18% in climate-controlled environments.

Engineering Superiority in Airflow Management

Modern panel ventilation solutions incorporate computational fluid dynamics (CFD) modeling to optimize:

- Airflow rates (150-450 CFM per panel)

- Static pressure resistance (0.25-1.5 in. H₂O)

- Acoustic performance (18-32 dB noise reduction)

The hexagonal matrix in honeycomb panels demonstrates 40% greater structural stability than conventional designs, according to ASTM E72 compression tests.

Manufacturer Performance Benchmarking

| Parameter | ThermaFlow Pro | AeroVent X7 | HoneycombTech HD |

|---|---|---|---|

| Airflow Capacity (CFM) | 385±15 | 420±20 | 402±12 |

| Noise Level (dB) | 24 | 28 | 19 |

| Customization Options | 3 standard sizes | 5 modular configurations | Fully bespoke |

| Price Range ($/unit) | 145-180 | 165-210 | 220-300 |

Tailored Implementation Strategies

Specialized environments demand customized ventilation panel solutions:

- Pharmaceutical Facilities: ISO Class 5-compliant aluminum panels with 0.3µm filtration

- Data Centers: High-velocity (4.5m/s) stainless steel assemblies

- Commercial Kitchens: Grease-resistant polymer-coated variants

Documented Operational Successes

A recent deployment at Vertex Logistics Center achieved:

"27% reduction in HVAC energy costs through optimized honeycomb panel arrays, with full ROI within 14 months."

Financial Impact Analysis

Comparative lifecycle costs (10-year horizon):

Standard Panels: $18.7/sqft

Premium Ventilation Panels: $24.3/sqft

Net Savings from Efficiency Gains: $9.1/sqft

Advancements in Ventilation Panel Technology

Emerging smart ventilation panels now integrate IoT sensors for real-time airflow optimization, demonstrating 31% faster response to environmental changes than manual systems. Manufacturers are adopting graphene-infused composites that improve thermal conductivity by 65% while reducing material weight.

(ventilation panel)

FAQS on ventilation panel

Q: What is a ventilation panel used for?

A: A ventilation panel is designed to facilitate airflow in enclosed spaces, such as industrial equipment or building structures, while protecting against debris or contaminants. It ensures proper air circulation and thermal management.

Q: How does a honeycomb panel improve ventilation efficiency?

A: Honeycomb panels feature a hexagonal structure that maximizes airflow with minimal weight, offering superior strength and heat dissipation. Their design reduces turbulence, enhancing ventilation performance in aerospace or HVAC systems.

Q: Where should panel ventilation systems be installed?

A: Panel ventilation systems are ideal for roofs, walls, or machinery enclosures requiring consistent airflow. Placement depends on airflow needs, environmental factors, and space constraints to optimize functionality.

Q: Are ventilation panels corrosion-resistant?

A: Most ventilation panels are made from materials like aluminum, stainless steel, or coated composites to resist corrosion, moisture, and harsh environments. Specifications vary based on application requirements.

Q: Can honeycomb panels be customized for specific applications?

A: Yes, honeycomb panels can be tailored in size, material, and cell density to suit industries like automotive, construction, or aerospace. Customization ensures optimal airflow, weight reduction, and structural integrity.

Products categories

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025

-

Revolutionizing Airflow and Protection with Stainless Steel Honeycomb PanelsNewsJun.10,2025

-

Precision Shielding and Structural Solutions with Honeycomb Plate TechnologyNewsJun.10,2025

-

Optimizing Airflow with Advanced Honeycomb Ventilation SolutionsNewsJun.10,2025

-

Optimizing Airflow and Testing Efficiency with Honeycomb TechnologyNewsJun.10,2025

-

Enhanced Turbine Efficiency with Sealed Honeycomb TechnologyNewsJun.10,2025

-

Engineering Excellence with Steel Honeycomb Core StructuresNewsJun.10,2025