- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Optimize pèfòmans aerodinamik ak Honeycomb Airflow Straighteners

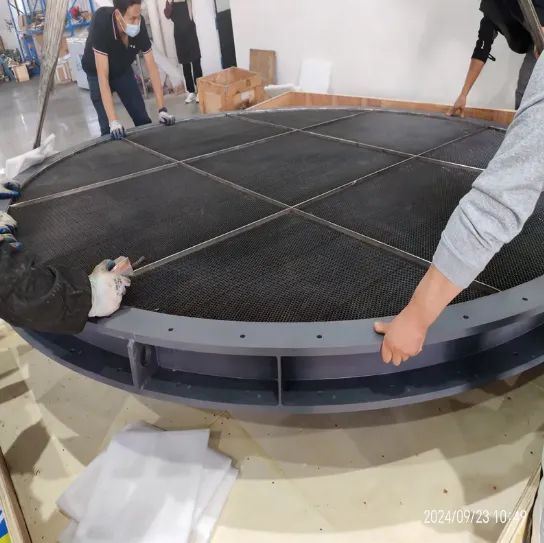

Lè li rive tès pèfòmans aerodinamik, presizyon ak inifòmite yo esansyèl. Sa a se kote itilize nan redresman lè admisyon epi siwo myèl asye pur estrikti antre nan jwèt. Lè yo asire koule lè lis ak ki estab, konpozan sa yo ede enjenyè evalye enpak fòm machin sou rezistans lè ak presizyon segondè. Nan atik sa a, nou pral eksplore ki jan siwo myèl fèy asye pur ak lòt redresman Airflow yo enpòtan anpil nan tès van tinèl otomobil ak wòl yo nan optimize aerodinamik machin yo.

Poukisa Honeycomb Nerjaveèi se ideyal pou Airflow redresman

Nan kè efektif airflow redressement se a siwo myèl asye pur estrikti, yon materyèl ki renome pou fòs li yo, durability, ak kapasite yo kontwole koule lè a. Nan tinèl van, siwo myèl fèy asye pur yo itilize pou kreye straighteners koule lè, ki fèt pou diminye tourbiyon ak amelyore inifòmite mouvman lè a. Estrikti sa yo pèmèt lè antre nan tinèl van an nan yon koule lis, laminar, asire ke tès ki vin apre yo tou de egzat ak repete.

Itilize nan siwo myèl asye pur provides several key advantages in this application. The uniformity of airflow is significantly enhanced due to the honeycomb’s consistent geometry, which guides the air in a controlled manner. This results in more precise aerodynamic measurements, as any fluctuation in airflow can lead to distorted test results. By using redresman lè admisyon te fè nan materyèl sa a, tinèl van an ka simulation kondisyon lè mond reyèl la pi byen, ede enjenyè pran pi bon desizyon sou konsepsyon machin.

Redresman Airflow ak wòl yo nan tès van tinèl otomobil

Air koule straighteners are essential in automotive wind tunnel testing, where understanding the interaction between a vehicle and the surrounding air is critical. The primary function of these straighteners is to ensure that air entering the wind tunnel is free of disturbances, allowing engineers to obtain reliable data on how a vehicle’s shape impacts air resistance. By achieving stable and uniform airflow, these straighteners make it possible to simulate aerodynamic conditions that closely match real-world scenarios.

Nan tès van tinèl, menm ti varyasyon nan koule lè ka gen efè enpòtan sou rezilta tès yo. Honeycomb Nerjaveèi estrikti, lè yo itilize kòm redresman airflow, elimine varyasyon sa yo, bay yon koule konstan ak kontwole nan lè. Sa a ede chèchè yo evalye kijan diferan konsepsyon machin yo afekte trennen, leve, ak pèfòmans aerodinamik an jeneral. Anplis de sa, li pèmèt pou evalyasyon egzak lòt faktè kritik tankou efikasite gaz, estabilite, ak karakteristik manyen.

Fòm nan yon machin jwe yon wòl kritik nan detèmine kijan li kominike ak lè a alantou li. Nan konsepsyon otomobil, diminye rezistans lè a se kle pou amelyore efikasite gaz, vitès, ak pèfòmans jeneral. Enpak fòm machin sou rezistans lè ka evalye ak gwo presizyon lè straighteners koule lè yo itilize nan konbinezon ak siwo myèl asye pur konpozan.

Lè w itilize siwo myèl fèy asye pur kòm yon pati nan admisyon lè straightener system, engineers can study the effects of different shapes on airflow with minimal interference. For example, the streamlined contours of a car will cause the air to flow more smoothly, whereas a boxy or irregular design may lead to turbulence and drag. The use of precise airflow rectifiers ensures that the air entering the wind tunnel is as uniform as possible, giving engineers the ability to accurately gauge how changes in shape affect the vehicle’s aerodynamics.

When it comes to aerodynamic testing, the importance of stability and uniformity in airflow cannot be overstated. For wind tunnel tests to be reliable, the airflow needs to be steady and consistent to ensure that the results are reflective of real-world conditions. This is especially important when testing vehicles, as even small discrepancies in airflow can significantly impact the accuracy of the data collected.

Honeycomb Nerjaveèi offers excellent stability due to its robust and resilient design. The honeycomb structure helps to direct airflow in a stable, predictable manner, which is essential for accurate aerodynamic testing. Whether testing cars, trucks, or other vehicles, the uniformity achieved by airflow rectifiers ensures that the airflow is as close to ideal as possible, giving researchers a clearer picture of how various vehicle shapes perform in a real-world environment.

Lavni an nan Airflow Straighteners nan Aerodynamics

Kòm endistri otomobil la ap kontinye inove, demann pou machin ki pi efikas ak pèfòmans-wo ap grandi. An repons a bezwen sa a, wòl nan siwo myèl asye pur epi straighteners koule lè nan tès tinèl van ap kontinye evolye. Avansman nan materyèl ak konsepsyon pral plis amelyore pèfòmans nan eleman sa yo, amelyore presizyon ak efikasite nan tès aerodinamik.

Yon devlopman kle ta ka entegrasyon sistèm dijital ak otomatik nan pwosesis tès la. Pa konbine siwo myèl fèy asye pur desen ak detèktè entelijan ak analiz done an tan reyèl, li pral posib pou optimize pwosesis tès la menm pi lwen. Sa a ta ka mennen nan sik tès pi vit, rezilta pi detaye, ak kapasite nan simulation modèl koule lè konplèks plis presizyon. Kòm konsepsyon machin vin pi konplike ak pèfòmans-kondwi, demann lan pou tès aerodinamik egzak yo ap kontinye kondwi inovasyon nan redresman Airflow ak wòl yo nan fòme avni an nan konsepsyon otomobil.

An konklizyon, la siwo myèl asye pur structure is integral to achieving stable and uniform airflow in wind tunnel testing. Whether used as redresman lè admisyon or airflow rectifiers, its role in aerodynamic performance testing is indispensable. With its ability to optimize airflow, reduce turbulence, and provide more reliable data, honeycomb-based designs will remain at the forefront of automotive engineering for years to come.

Kategori pwodwi yo

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNouvèlJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNouvèlJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNouvèlJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNouvèlJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNouvèlJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNouvèlJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNouvèlJul.11,2025