- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

利用蜂窩氣流整流器優化空氣動力學性能

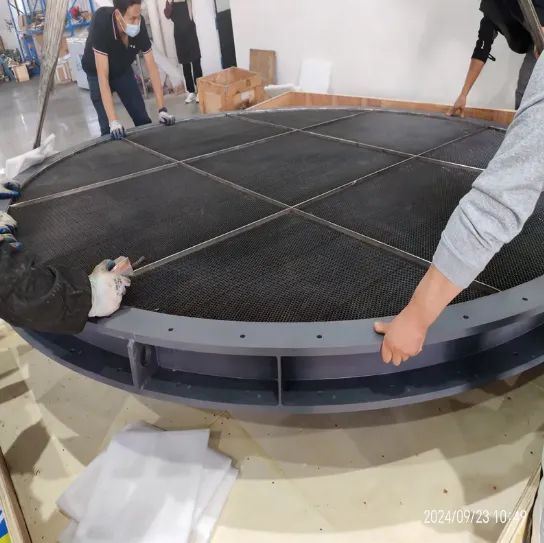

在進行空氣動力學性能測試時,精度和均勻性至關重要。這就是使用 進氣矯正器 和 蜂巢不鏽鋼 結構開始發揮作用。透過確保平穩穩定的氣流,這些零件可幫助工程師高精度地評估車輛形狀對空氣阻力的影響。在本文中,我們將探討如何 蜂巢不鏽鋼板 和其他氣流整流器在汽車風洞測試和優化車輛空氣動力學中起著至關重要的作用。

為什麼蜂巢不銹鋼是氣流矯直的理想選擇

有效氣流矯直的核心是 蜂巢不鏽鋼 結構,這種材料以其強度、耐用性和調節氣流的能力而聞名。在風洞中, 蜂巢不鏽鋼板 用於創建 氣流整流器,旨在減少湍流並提高空氣流動的均勻性。這些結構允許空氣以平穩的層流進入風洞,確保後續測試的準確性和可重複性。

使用 蜂巢不鏽鋼 provides several key advantages in this application. The uniformity of airflow is significantly enhanced due to the honeycomb’s consistent geometry, which guides the air in a controlled manner. This results in more precise aerodynamic measurements, as any fluctuation in airflow can lead to distorted test results. By using 進氣矯正器 採用這種材料製成的風洞可以更準確地模擬真實世界的空氣狀況,幫助工程師更好地決策車輛設計。

氣流整流器及其在汽車風洞測試中的作用

氣流整流器 are essential in automotive wind tunnel testing, where understanding the interaction between a vehicle and the surrounding air is critical. The primary function of these straighteners is to ensure that air entering the wind tunnel is free of disturbances, allowing engineers to obtain reliable data on how a vehicle’s shape impacts air resistance. By achieving stable and uniform airflow, these straighteners make it possible to simulate aerodynamic conditions that closely match real-world scenarios.

在風洞測試中,即使氣流的微小變化也會對測試結果產生重大影響。 蜂巢不鏽鋼 當結構用作氣流整流器時,可以消除這些變化,提供恆定且受控的氣流。這有助於研究人員評估不同的車輛設計如何影響阻力、升力和整體空氣動力學性能。此外,它還可以精確評估其他關鍵因素,例如燃油效率、穩定性和操控特性。

車輛的形狀在決定它如何與周圍空氣相互作用方面起著至關重要的作用。在汽車設計中,降低空氣阻力是提高燃油效率、速度和整體性能的關鍵。當車輛形狀對空氣阻力的影響 氣流整流器 與 蜂巢不鏽鋼 成分。

透過使用 蜂巢不鏽鋼板 作為 進氣矯正器 system, engineers can study the effects of different shapes on airflow with minimal interference. For example, the streamlined contours of a car will cause the air to flow more smoothly, whereas a boxy or irregular design may lead to turbulence and drag. The use of precise airflow rectifiers ensures that the air entering the wind tunnel is as uniform as possible, giving engineers the ability to accurately gauge how changes in shape affect the vehicle’s aerodynamics.

When it comes to aerodynamic testing, the importance of stability and uniformity in airflow cannot be overstated. For wind tunnel tests to be reliable, the airflow needs to be steady and consistent to ensure that the results are reflective of real-world conditions. This is especially important when testing vehicles, as even small discrepancies in airflow can significantly impact the accuracy of the data collected.

蜂巢不鏽鋼 offers excellent stability due to its robust and resilient design. The honeycomb structure helps to direct airflow in a stable, predictable manner, which is essential for accurate aerodynamic testing. Whether testing cars, trucks, or other vehicles, the uniformity achieved by airflow rectifiers ensures that the airflow is as close to ideal as possible, giving researchers a clearer picture of how various vehicle shapes perform in a real-world environment.

空氣動力學中氣流整流器的未來

隨著汽車產業的不斷創新,對更有效率、高性能汽車的需求也日益增長。為了滿足這項需求, 蜂巢不鏽鋼 和 氣流整流器 風洞測試將繼續發展。材料和設計的進步將進一步提高這些零件的性能,並提高空氣動力學測試的準確性和效率。

一個關鍵的發展可能是將數位和自動化系統整合到測試過程中。透過結合 蜂巢不鏽鋼板 透過採用智慧感測器和即時數據分析的設計,可以進一步優化測試過程。這可以帶來更快的測試週期、更詳細的結果以及更準確地模擬複雜氣流模式的能力。隨著車輛設計變得越來越複雜和性能驅動,對精確空氣動力學測試的需求將繼續推動氣流整流器的創新及其在塑造汽車設計未來中的作用。

綜上所述, 蜂巢不鏽鋼 structure is integral to achieving stable and uniform airflow in wind tunnel testing. Whether used as 進氣矯正器 or airflow rectifiers, its role in aerodynamic performance testing is indispensable. With its ability to optimize airflow, reduce turbulence, and provide more reliable data, honeycomb-based designs will remain at the forefront of automotive engineering for years to come.

產品類別

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation Solutions訊息Jul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and Protection訊息Jul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing Solutions訊息Jul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic Protection訊息Jul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel Solutions訊息Jul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core Solutions訊息Jul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI Control訊息Jul.11,2025