- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

ਹਨੀਕੌਂਬ ਏਅਰਫਲੋ ਸਟ੍ਰੇਟਨਰ ਨਾਲ ਐਰੋਡਾਇਨਾਮਿਕ ਪ੍ਰਦਰਸ਼ਨ ਨੂੰ ਅਨੁਕੂਲ ਬਣਾਉਣਾ

ਜਦੋਂ ਏਅਰੋਡਾਇਨਾਮਿਕ ਪ੍ਰਦਰਸ਼ਨ ਟੈਸਟਿੰਗ ਦੀ ਗੱਲ ਆਉਂਦੀ ਹੈ, ਤਾਂ ਸ਼ੁੱਧਤਾ ਅਤੇ ਇਕਸਾਰਤਾ ਸਭ ਤੋਂ ਮਹੱਤਵਪੂਰਨ ਹੁੰਦੀ ਹੈ। ਇਹ ਉਹ ਥਾਂ ਹੈ ਜਿੱਥੇ ਵਰਤੋਂ ਇਨਟੇਕ ਏਅਰ ਸਟ੍ਰੇਟਨਰ ਅਤੇ ਹਨੀਕੌਂਬ ਸਟੇਨਲੈਸ ਸਟੀਲ ਬਣਤਰਾਂ ਕੰਮ ਵਿੱਚ ਆਉਂਦੀਆਂ ਹਨ। ਨਿਰਵਿਘਨ ਅਤੇ ਸਥਿਰ ਹਵਾ ਦੇ ਪ੍ਰਵਾਹ ਨੂੰ ਯਕੀਨੀ ਬਣਾ ਕੇ, ਇਹ ਹਿੱਸੇ ਇੰਜੀਨੀਅਰਾਂ ਨੂੰ ਉੱਚ ਸ਼ੁੱਧਤਾ ਨਾਲ ਹਵਾ ਪ੍ਰਤੀਰੋਧ 'ਤੇ ਵਾਹਨ ਦੀ ਸ਼ਕਲ ਦੇ ਪ੍ਰਭਾਵ ਦਾ ਮੁਲਾਂਕਣ ਕਰਨ ਵਿੱਚ ਮਦਦ ਕਰਦੇ ਹਨ। ਇਸ ਲੇਖ ਵਿੱਚ, ਅਸੀਂ ਖੋਜ ਕਰਾਂਗੇ ਕਿ ਕਿਵੇਂ ਹਨੀਕੌਂਬ ਸਟੇਨਲੈਸ ਸਟੀਲ ਸ਼ੀਟ ਅਤੇ ਹੋਰ ਏਅਰਫਲੋ ਰੀਕਟੀਫਾਇਰ ਆਟੋਮੋਟਿਵ ਵਿੰਡ ਟਨਲ ਟੈਸਟਿੰਗ ਅਤੇ ਵਾਹਨ ਐਰੋਡਾਇਨਾਮਿਕਸ ਨੂੰ ਅਨੁਕੂਲ ਬਣਾਉਣ ਵਿੱਚ ਉਹਨਾਂ ਦੀ ਭੂਮਿਕਾ ਵਿੱਚ ਮਹੱਤਵਪੂਰਨ ਹਨ।

ਹਵਾ ਦੇ ਪ੍ਰਵਾਹ ਨੂੰ ਸਿੱਧਾ ਕਰਨ ਲਈ ਹਨੀਕੌਂਬ ਸਟੇਨਲੈੱਸ ਸਟੀਲ ਆਦਰਸ਼ ਕਿਉਂ ਹੈ?

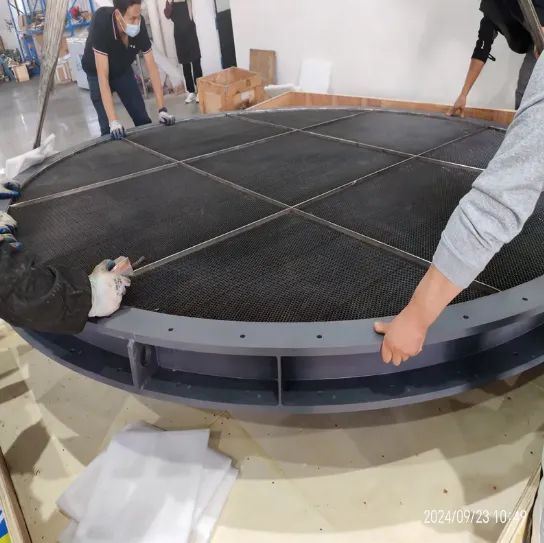

ਪ੍ਰਭਾਵਸ਼ਾਲੀ ਹਵਾ ਦੇ ਪ੍ਰਵਾਹ ਨੂੰ ਸਿੱਧਾ ਕਰਨ ਦੇ ਕੇਂਦਰ ਵਿੱਚ ਹੈ ਹਨੀਕੌਂਬ ਸਟੇਨਲੈਸ ਸਟੀਲ ਬਣਤਰ, ਇੱਕ ਸਮੱਗਰੀ ਜੋ ਆਪਣੀ ਤਾਕਤ, ਟਿਕਾਊਤਾ, ਅਤੇ ਹਵਾ ਦੇ ਪ੍ਰਵਾਹ ਨੂੰ ਨਿਯਮਤ ਕਰਨ ਦੀ ਯੋਗਤਾ ਲਈ ਮਸ਼ਹੂਰ ਹੈ। ਹਵਾ ਸੁਰੰਗਾਂ ਵਿੱਚ, ਹਨੀਕੌਂਬ ਸਟੇਨਲੈਸ ਸਟੀਲ ਸ਼ੀਟਾਂ ਬਣਾਉਣ ਲਈ ਵਰਤੇ ਜਾਂਦੇ ਹਨ ਹਵਾ ਦੇ ਪ੍ਰਵਾਹ ਨੂੰ ਸਿੱਧਾ ਕਰਨ ਵਾਲੇ, ਜੋ ਕਿ ਗੜਬੜ ਨੂੰ ਘਟਾਉਣ ਅਤੇ ਹਵਾ ਦੀ ਗਤੀ ਦੀ ਇਕਸਾਰਤਾ ਨੂੰ ਬਿਹਤਰ ਬਣਾਉਣ ਲਈ ਤਿਆਰ ਕੀਤੇ ਗਏ ਹਨ। ਇਹ ਬਣਤਰ ਹਵਾ ਨੂੰ ਇੱਕ ਨਿਰਵਿਘਨ, ਲੈਮੀਨਰ ਪ੍ਰਵਾਹ ਵਿੱਚ ਹਵਾ ਸੁਰੰਗ ਵਿੱਚ ਦਾਖਲ ਹੋਣ ਦਿੰਦੇ ਹਨ, ਇਹ ਯਕੀਨੀ ਬਣਾਉਂਦੇ ਹਨ ਕਿ ਬਾਅਦ ਦੇ ਟੈਸਟ ਸਹੀ ਅਤੇ ਦੁਹਰਾਉਣ ਯੋਗ ਦੋਵੇਂ ਹੋਣ।

ਦੀ ਵਰਤੋਂ ਹਨੀਕੌਂਬ ਸਟੇਨਲੈਸ ਸਟੀਲ provides several key advantages in this application. The uniformity of airflow is significantly enhanced due to the honeycomb’s consistent geometry, which guides the air in a controlled manner. This results in more precise aerodynamic measurements, as any fluctuation in airflow can lead to distorted test results. By using ਇਨਟੇਕ ਏਅਰ ਸਟ੍ਰੇਟਨਰ ਇਸ ਸਮੱਗਰੀ ਤੋਂ ਬਣੀ, ਵਿੰਡ ਟਨਲ ਅਸਲ-ਸੰਸਾਰ ਦੀਆਂ ਹਵਾ ਦੀਆਂ ਸਥਿਤੀਆਂ ਨੂੰ ਵਧੇਰੇ ਸਹੀ ਢੰਗ ਨਾਲ ਨਕਲ ਕਰ ਸਕਦੀ ਹੈ, ਜਿਸ ਨਾਲ ਇੰਜੀਨੀਅਰਾਂ ਨੂੰ ਵਾਹਨ ਡਿਜ਼ਾਈਨ ਬਾਰੇ ਬਿਹਤਰ ਫੈਸਲੇ ਲੈਣ ਵਿੱਚ ਮਦਦ ਮਿਲਦੀ ਹੈ।

ਆਟੋਮੋਟਿਵ ਵਿੰਡ ਟਨਲ ਟੈਸਟਿੰਗ ਵਿੱਚ ਏਅਰਫਲੋ ਰੀਕਟੀਫਾਇਰ ਅਤੇ ਉਨ੍ਹਾਂ ਦੀ ਭੂਮਿਕਾ

ਹਵਾ ਦੇ ਪ੍ਰਵਾਹ ਨੂੰ ਸਿੱਧਾ ਕਰਨ ਵਾਲੇ are essential in automotive wind tunnel testing, where understanding the interaction between a vehicle and the surrounding air is critical. The primary function of these straighteners is to ensure that air entering the wind tunnel is free of disturbances, allowing engineers to obtain reliable data on how a vehicle’s shape impacts air resistance. By achieving stable and uniform airflow, these straighteners make it possible to simulate aerodynamic conditions that closely match real-world scenarios.

ਵਿੰਡ ਟਨਲ ਟੈਸਟਿੰਗ ਵਿੱਚ, ਹਵਾ ਦੇ ਪ੍ਰਵਾਹ ਵਿੱਚ ਮਾਮੂਲੀ ਭਿੰਨਤਾਵਾਂ ਵੀ ਟੈਸਟ ਦੇ ਨਤੀਜਿਆਂ 'ਤੇ ਮਹੱਤਵਪੂਰਨ ਪ੍ਰਭਾਵ ਪਾ ਸਕਦੀਆਂ ਹਨ। ਸ਼ਹਿਦ ਦਾ ਸਟੇਨਲੈਸ ਸਟੀਲ ਜਦੋਂ ਏਅਰਫਲੋ ਰੀਕਟੀਫਾਇਰ ਵਜੋਂ ਵਰਤੇ ਜਾਂਦੇ ਹਨ, ਤਾਂ ਬਣਤਰ ਇਹਨਾਂ ਭਿੰਨਤਾਵਾਂ ਨੂੰ ਖਤਮ ਕਰਦੇ ਹਨ, ਹਵਾ ਦਾ ਇੱਕ ਨਿਰੰਤਰ ਅਤੇ ਨਿਯੰਤਰਿਤ ਪ੍ਰਵਾਹ ਪ੍ਰਦਾਨ ਕਰਦੇ ਹਨ। ਇਹ ਖੋਜਕਰਤਾਵਾਂ ਨੂੰ ਇਹ ਮੁਲਾਂਕਣ ਕਰਨ ਵਿੱਚ ਮਦਦ ਕਰਦਾ ਹੈ ਕਿ ਵੱਖ-ਵੱਖ ਵਾਹਨ ਡਿਜ਼ਾਈਨ ਡਰੈਗ, ਲਿਫਟ ਅਤੇ ਸਮੁੱਚੇ ਐਰੋਡਾਇਨਾਮਿਕ ਪ੍ਰਦਰਸ਼ਨ ਨੂੰ ਕਿਵੇਂ ਪ੍ਰਭਾਵਤ ਕਰਦੇ ਹਨ। ਇਸ ਤੋਂ ਇਲਾਵਾ, ਇਹ ਬਾਲਣ ਕੁਸ਼ਲਤਾ, ਸਥਿਰਤਾ ਅਤੇ ਹੈਂਡਲਿੰਗ ਵਿਸ਼ੇਸ਼ਤਾਵਾਂ ਵਰਗੇ ਹੋਰ ਮਹੱਤਵਪੂਰਨ ਕਾਰਕਾਂ ਦੇ ਸਹੀ ਮੁਲਾਂਕਣ ਦੀ ਆਗਿਆ ਦਿੰਦਾ ਹੈ।

ਵਾਹਨ ਦੀ ਸ਼ਕਲ ਇਹ ਨਿਰਧਾਰਤ ਕਰਨ ਵਿੱਚ ਇੱਕ ਮਹੱਤਵਪੂਰਨ ਭੂਮਿਕਾ ਨਿਭਾਉਂਦੀ ਹੈ ਕਿ ਇਹ ਆਪਣੇ ਆਲੇ ਦੁਆਲੇ ਦੀ ਹਵਾ ਨਾਲ ਕਿਵੇਂ ਪਰਸਪਰ ਪ੍ਰਭਾਵ ਪਾਉਂਦਾ ਹੈ। ਆਟੋਮੋਟਿਵ ਡਿਜ਼ਾਈਨ ਵਿੱਚ, ਹਵਾ ਪ੍ਰਤੀਰੋਧ ਨੂੰ ਘਟਾਉਣਾ ਬਾਲਣ ਕੁਸ਼ਲਤਾ, ਗਤੀ ਅਤੇ ਸਮੁੱਚੀ ਕਾਰਗੁਜ਼ਾਰੀ ਨੂੰ ਬਿਹਤਰ ਬਣਾਉਣ ਲਈ ਕੁੰਜੀ ਹੈ। ਵਾਹਨ ਦੀ ਸ਼ਕਲ ਦੇ ਹਵਾ ਪ੍ਰਤੀਰੋਧ 'ਤੇ ਪ੍ਰਭਾਵ ਦਾ ਮੁਲਾਂਕਣ ਬਹੁਤ ਸ਼ੁੱਧਤਾ ਨਾਲ ਕੀਤਾ ਜਾ ਸਕਦਾ ਹੈ ਜਦੋਂ ਹਵਾ ਦੇ ਪ੍ਰਵਾਹ ਨੂੰ ਸਿੱਧਾ ਕਰਨ ਵਾਲੇ ਦੇ ਨਾਲ ਸੁਮੇਲ ਵਿੱਚ ਵਰਤੇ ਜਾਂਦੇ ਹਨ ਹਨੀਕੌਂਬ ਸਟੇਨਲੈਸ ਸਟੀਲ ਹਿੱਸੇ।

ਵਰਤ ਕੇ ਹਨੀਕੌਂਬ ਸਟੇਨਲੈਸ ਸਟੀਲ ਸ਼ੀਟ ਦੇ ਹਿੱਸੇ ਵਜੋਂ ਇਨਟੇਕ ਏਅਰ ਸਟ੍ਰੇਟਨਰ system, engineers can study the effects of different shapes on airflow with minimal interference. For example, the streamlined contours of a car will cause the air to flow more smoothly, whereas a boxy or irregular design may lead to turbulence and drag. The use of precise airflow rectifiers ensures that the air entering the wind tunnel is as uniform as possible, giving engineers the ability to accurately gauge how changes in shape affect the vehicle’s aerodynamics.

When it comes to aerodynamic testing, the importance of stability and uniformity in airflow cannot be overstated. For wind tunnel tests to be reliable, the airflow needs to be steady and consistent to ensure that the results are reflective of real-world conditions. This is especially important when testing vehicles, as even small discrepancies in airflow can significantly impact the accuracy of the data collected.

ਸ਼ਹਿਦ ਦਾ ਸਟੇਨਲੈਸ ਸਟੀਲ offers excellent stability due to its robust and resilient design. The honeycomb structure helps to direct airflow in a stable, predictable manner, which is essential for accurate aerodynamic testing. Whether testing cars, trucks, or other vehicles, the uniformity achieved by airflow rectifiers ensures that the airflow is as close to ideal as possible, giving researchers a clearer picture of how various vehicle shapes perform in a real-world environment.

ਐਰੋਡਾਇਨਾਮਿਕਸ ਵਿੱਚ ਏਅਰਫਲੋ ਸਟ੍ਰੇਟਨਰ ਦਾ ਭਵਿੱਖ

ਜਿਵੇਂ-ਜਿਵੇਂ ਆਟੋਮੋਟਿਵ ਉਦਯੋਗ ਨਵੀਨਤਾ ਕਰਨਾ ਜਾਰੀ ਰੱਖਦਾ ਹੈ, ਵਧੇਰੇ ਕੁਸ਼ਲ ਅਤੇ ਉੱਚ-ਪ੍ਰਦਰਸ਼ਨ ਵਾਲੇ ਵਾਹਨਾਂ ਦੀ ਮੰਗ ਵਧਦੀ ਜਾਂਦੀ ਹੈ। ਇਸ ਲੋੜ ਦੇ ਜਵਾਬ ਵਿੱਚ, ਦੀ ਭੂਮਿਕਾ ਹਨੀਕੌਂਬ ਸਟੇਨਲੈਸ ਸਟੀਲ ਅਤੇ ਹਵਾ ਦੇ ਪ੍ਰਵਾਹ ਨੂੰ ਸਿੱਧਾ ਕਰਨ ਵਾਲੇ ਹਵਾ ਸੁਰੰਗ ਟੈਸਟਿੰਗ ਵਿੱਚ ਵਿਕਾਸ ਜਾਰੀ ਰਹੇਗਾ। ਸਮੱਗਰੀ ਅਤੇ ਡਿਜ਼ਾਈਨ ਵਿੱਚ ਤਰੱਕੀ ਇਹਨਾਂ ਹਿੱਸਿਆਂ ਦੀ ਕਾਰਗੁਜ਼ਾਰੀ ਨੂੰ ਹੋਰ ਵਧਾਏਗੀ, ਜਿਸ ਨਾਲ ਐਰੋਡਾਇਨਾਮਿਕ ਟੈਸਟਿੰਗ ਦੀ ਸ਼ੁੱਧਤਾ ਅਤੇ ਕੁਸ਼ਲਤਾ ਵਿੱਚ ਸੁਧਾਰ ਹੋਵੇਗਾ।

ਇੱਕ ਮੁੱਖ ਵਿਕਾਸ ਟੈਸਟਿੰਗ ਪ੍ਰਕਿਰਿਆ ਵਿੱਚ ਡਿਜੀਟਲ ਅਤੇ ਆਟੋਮੇਟਿਡ ਸਿਸਟਮਾਂ ਦਾ ਏਕੀਕਰਨ ਹੋ ਸਕਦਾ ਹੈ। ਜੋੜ ਕੇ ਹਨੀਕੌਂਬ ਸਟੇਨਲੈਸ ਸਟੀਲ ਸ਼ੀਟ ਸਮਾਰਟ ਸੈਂਸਰਾਂ ਅਤੇ ਰੀਅਲ-ਟਾਈਮ ਡੇਟਾ ਵਿਸ਼ਲੇਸ਼ਣ ਵਾਲੇ ਡਿਜ਼ਾਈਨ, ਟੈਸਟਿੰਗ ਪ੍ਰਕਿਰਿਆ ਨੂੰ ਹੋਰ ਵੀ ਅਨੁਕੂਲ ਬਣਾਉਣਾ ਸੰਭਵ ਹੋਵੇਗਾ। ਇਸ ਨਾਲ ਤੇਜ਼ ਟੈਸਟਿੰਗ ਚੱਕਰ, ਵਧੇਰੇ ਵਿਸਤ੍ਰਿਤ ਨਤੀਜੇ, ਅਤੇ ਗੁੰਝਲਦਾਰ ਏਅਰਫਲੋ ਪੈਟਰਨਾਂ ਨੂੰ ਵਧੇਰੇ ਸਹੀ ਢੰਗ ਨਾਲ ਨਕਲ ਕਰਨ ਦੀ ਯੋਗਤਾ ਮਿਲ ਸਕਦੀ ਹੈ। ਜਿਵੇਂ-ਜਿਵੇਂ ਵਾਹਨ ਡਿਜ਼ਾਈਨ ਵਧੇਰੇ ਗੁੰਝਲਦਾਰ ਅਤੇ ਪ੍ਰਦਰਸ਼ਨ-ਅਧਾਰਿਤ ਹੁੰਦਾ ਜਾਂਦਾ ਹੈ, ਸਟੀਕ ਏਅਰੋਡਾਇਨਾਮਿਕ ਟੈਸਟਿੰਗ ਦੀ ਮੰਗ ਏਅਰਫਲੋ ਰੀਕਟੀਫਾਇਰ ਦੀ ਨਵੀਨਤਾ ਅਤੇ ਆਟੋਮੋਟਿਵ ਡਿਜ਼ਾਈਨ ਦੇ ਭਵਿੱਖ ਨੂੰ ਆਕਾਰ ਦੇਣ ਵਿੱਚ ਉਨ੍ਹਾਂ ਦੀ ਭੂਮਿਕਾ ਨੂੰ ਅੱਗੇ ਵਧਾਉਂਦੀ ਰਹੇਗੀ।

ਸਿੱਟੇ ਵਜੋਂ, ਹਨੀਕੌਂਬ ਸਟੇਨਲੈਸ ਸਟੀਲ structure is integral to achieving stable and uniform airflow in wind tunnel testing. Whether used as ਇਨਟੇਕ ਏਅਰ ਸਟ੍ਰੇਟਨਰ or airflow rectifiers, its role in aerodynamic performance testing is indispensable. With its ability to optimize airflow, reduce turbulence, and provide more reliable data, honeycomb-based designs will remain at the forefront of automotive engineering for years to come.

ਉਤਪਾਦਾਂ ਦੀਆਂ ਸ਼੍ਰੇਣੀਆਂ

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation Solutionsਖ਼ਬਰਾਂJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and Protectionਖ਼ਬਰਾਂJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing Solutionsਖ਼ਬਰਾਂJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic Protectionਖ਼ਬਰਾਂJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel Solutionsਖ਼ਬਰਾਂJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core Solutionsਖ਼ਬਰਾਂJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI Controlਖ਼ਬਰਾਂJul.11,2025