- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Ngoptimalake Kinerja Aerodinamis karo Honeycomb Airflow Straighteners

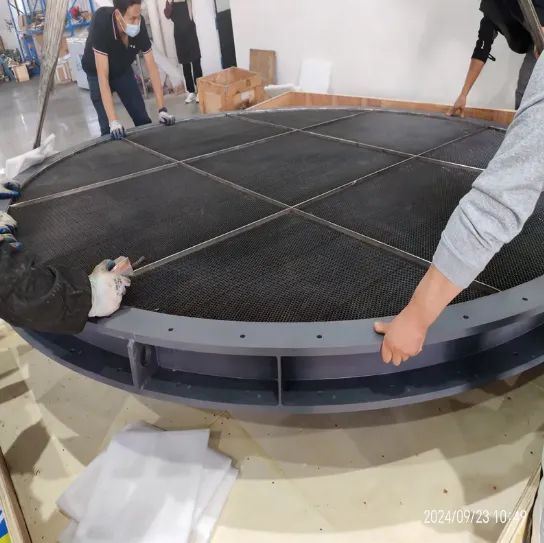

Nalika nerangake tes kinerja aerodinamis, presisi lan keseragaman sing paling penting. Iki ngendi nggunakake pelurus udara asupan lan sarang madu stainless steel struktur teka menyang muter. Kanthi mesthekake aliran udara sing lancar lan stabil, komponen kasebut mbantu para insinyur ngevaluasi pengaruh bentuk kendaraan ing resistensi udara kanthi akurasi sing dhuwur. Ing artikel iki, kita bakal njelajah carane lembaran baja tahan karat sarang madu lan rectifier aliran udara liyane penting ing tes trowongan angin otomotif lan perane kanggo ngoptimalake aerodinamika kendaraan.

Napa Stainless Steel Honeycomb Cocog kanggo Straightening Aliran Udara

Ing jantung straightening aliran udara efektif yaiku sarang madu stainless steel struktur, materi sing misuwur amarga kekuatan, daya tahan, lan kemampuan kanggo ngatur aliran udara. Ing trowongan angin, lembaran stainless steel honeycomb digunakake kanggo nggawe straighteners aliran udara, sing dirancang kanggo nyuda turbulensi lan nambah keseragaman gerakan udara. Struktur kasebut ngidini hawa mlebu terowongan angin kanthi aliran laminar sing lancar, supaya tes sabanjure akurat lan bisa diulang.

Panganggone sarang madu stainless steel provides several key advantages in this application. The uniformity of airflow is significantly enhanced due to the honeycomb’s consistent geometry, which guides the air in a controlled manner. This results in more precise aerodynamic measurements, as any fluctuation in airflow can lead to distorted test results. By using pelurus udara asupan digawe saka materi iki, trowongan angin bisa simulasi kahanan online nyata luwih akurat, ngewangi engineers pancasan luwih apik babagan desain kendaraan.

Penyearah Aliran Udara lan Perane ing Tes Tunnel Angin Otomotif

Straighteners aliran udara are essential in automotive wind tunnel testing, where understanding the interaction between a vehicle and the surrounding air is critical. The primary function of these straighteners is to ensure that air entering the wind tunnel is free of disturbances, allowing engineers to obtain reliable data on how a vehicle’s shape impacts air resistance. By achieving stable and uniform airflow, these straighteners make it possible to simulate aerodynamic conditions that closely match real-world scenarios.

Ing tes trowongan angin, sanajan variasi aliran udara sing sithik bisa duwe pengaruh sing signifikan ing asil tes. Baja tahan karat sarang madu struktur, nalika digunakake minangka rectifier airflow, ngilangi variasi kasebut, nyedhiyakake aliran hawa sing konstan lan dikontrol. Iki mbantu para peneliti netepake kepiye desain kendaraan sing beda-beda mengaruhi kinerja seret, angkat, lan aerodinamis sakabèhé. Kajaba iku, ngidini evaluasi sing tepat babagan faktor kritis liyane kayata efisiensi bahan bakar, stabilitas, lan karakteristik penanganan.

Bentuk kendaraan nduweni peran kritis kanggo nemtokake cara interaksi karo udara ing sakubenge. Ing desain otomotif, nyuda resistensi udara minangka kunci kanggo ningkatake efisiensi bahan bakar, kacepetan, lan kinerja sakabèhé. Dampak saka wangun kendaraan ing resistance udhara bisa ditaksir kanthi tliti banget nalika straighteners aliran udara digunakake ing kombinasi karo sarang madu stainless steel komponen.

Kanthi nggunakake lembaran baja tahan karat sarang madu minangka bagéan saka pelurus udara intake system, engineers can study the effects of different shapes on airflow with minimal interference. For example, the streamlined contours of a car will cause the air to flow more smoothly, whereas a boxy or irregular design may lead to turbulence and drag. The use of precise airflow rectifiers ensures that the air entering the wind tunnel is as uniform as possible, giving engineers the ability to accurately gauge how changes in shape affect the vehicle’s aerodynamics.

When it comes to aerodynamic testing, the importance of stability and uniformity in airflow cannot be overstated. For wind tunnel tests to be reliable, the airflow needs to be steady and consistent to ensure that the results are reflective of real-world conditions. This is especially important when testing vehicles, as even small discrepancies in airflow can significantly impact the accuracy of the data collected.

Baja tahan karat sarang madu offers excellent stability due to its robust and resilient design. The honeycomb structure helps to direct airflow in a stable, predictable manner, which is essential for accurate aerodynamic testing. Whether testing cars, trucks, or other vehicles, the uniformity achieved by airflow rectifiers ensures that the airflow is as close to ideal as possible, giving researchers a clearer picture of how various vehicle shapes perform in a real-world environment.

Masa Depan Pelurus Aliran Udara ing Aerodinamika

Nalika industri otomotif terus berinovasi, panjaluk kendaraan sing luwih efisien lan berkinerja tinggi mundhak. Nanggepi kabutuhan iki, peran saka sarang madu stainless steel lan straighteners aliran udara ing testing trowongan angin bakal terus berkembang. Kemajuan ing bahan lan desain bakal nambah kinerja komponen kasebut, nambah akurasi lan efisiensi tes aerodinamis.

Salah sawijining pangembangan utama bisa dadi integrasi sistem digital lan otomatis menyang proses tes. Kanthi nggabungake lembaran baja tahan karat sarang madu desain karo sensor pinter lan analisis data nyata-wektu, iku bakal bisa kanggo ngoptimalake proses testing malah luwih. Iki bisa nyebabake siklus tes sing luwih cepet, asil sing luwih rinci, lan kemampuan kanggo simulasi pola aliran udara sing kompleks kanthi luwih akurat. Nalika desain kendaraan dadi luwih rumit lan didorong kinerja, panjaluk tes aerodinamis sing tepat bakal terus nyurung inovasi penyearah aliran udara lan perane kanggo mbentuk masa depan desain otomotif.

Ing kesimpulan, ing sarang madu stainless steel structure is integral to achieving stable and uniform airflow in wind tunnel testing. Whether used as pelurus udara asupan or airflow rectifiers, its role in aerodynamic performance testing is indispensable. With its ability to optimize airflow, reduce turbulence, and provide more reliable data, honeycomb-based designs will remain at the forefront of automotive engineering for years to come.

Kategori produk

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsKabarJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionKabarJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsKabarJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionKabarJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsKabarJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsKabarJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlKabarJul.11,2025