- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 13, 2025 10:34

Back to list

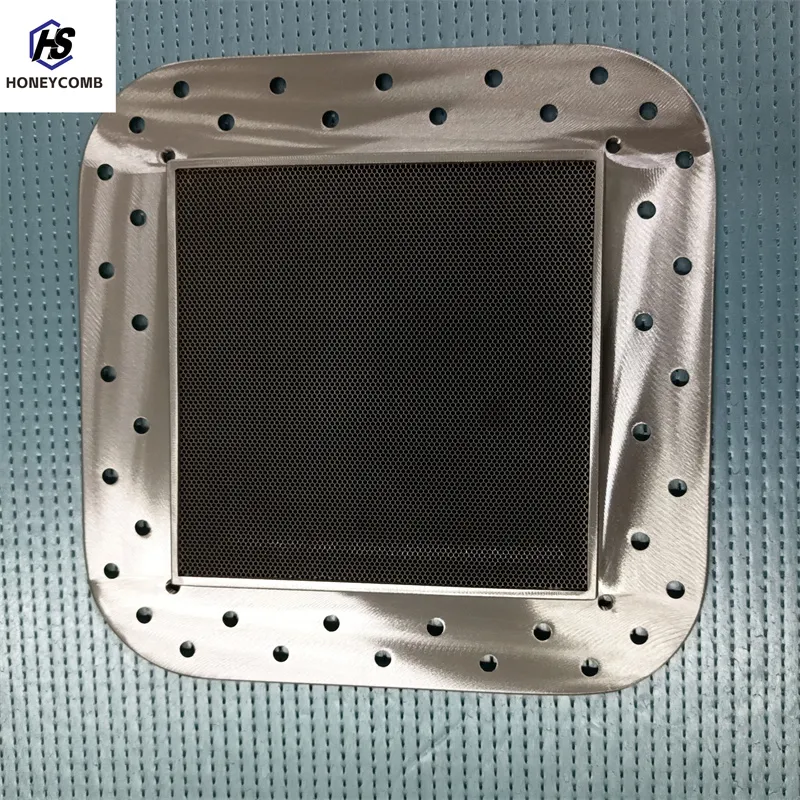

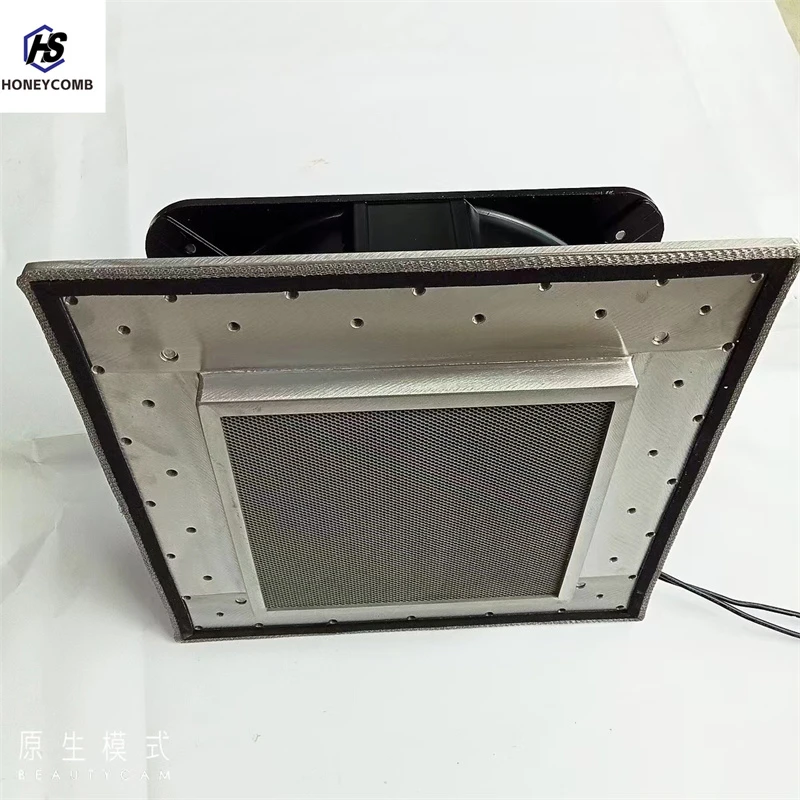

stainless steel honeycomb mesh

The Honeycomb Carbon Core An Innovative Leap in Product Development

Certified Expertise in Production The production of honeycomb carbon cores requires stringent quality control and expertise. Companies specializing in these materials invest heavily in R&D to ensure the highest standards are met. This becomes a critical point of trust and authority; knowing a product is crafted with precision and backed by industry certifications provides users with the confidence necessary for applications demanding reliability and resilience. Empowering Sustainable Practices Incorporating a honeycomb carbon core into product designs aligns with global sustainability goals, as it contributes to energy efficiency and reduces overall material waste. The production process itself has been refined to minimize environmental impact, an essential consideration for consumers and industries committed to ecological responsibility. These cores are often recyclable and have a lower carbon footprint compared to conventional materials, advancing circular economy principles. The Future Horizon Anticipating future trends, the versatility of honeycomb carbon cores will see their adoption in emerging fields such as renewable energy solutions, particularly in the wind and solar power industries. Panels utilizing these cores can be crafted to endure harsh environmental conditions while maintaining structural integrity, promoting the advancement of sustainable energy. In conclusion, the honeycomb carbon core represents a significant milestone in modern engineering and material science. Its implementation across various sectors underscores the importance of innovation driven by nature-inspired designs, professional expertise, and a commitment to sustainability. As we continue to push the boundaries of what’s possible, the honeycomb carbon core stands out as a testament to the ingenuity and potential that advanced materials bring to the table.

Certified Expertise in Production The production of honeycomb carbon cores requires stringent quality control and expertise. Companies specializing in these materials invest heavily in R&D to ensure the highest standards are met. This becomes a critical point of trust and authority; knowing a product is crafted with precision and backed by industry certifications provides users with the confidence necessary for applications demanding reliability and resilience. Empowering Sustainable Practices Incorporating a honeycomb carbon core into product designs aligns with global sustainability goals, as it contributes to energy efficiency and reduces overall material waste. The production process itself has been refined to minimize environmental impact, an essential consideration for consumers and industries committed to ecological responsibility. These cores are often recyclable and have a lower carbon footprint compared to conventional materials, advancing circular economy principles. The Future Horizon Anticipating future trends, the versatility of honeycomb carbon cores will see their adoption in emerging fields such as renewable energy solutions, particularly in the wind and solar power industries. Panels utilizing these cores can be crafted to endure harsh environmental conditions while maintaining structural integrity, promoting the advancement of sustainable energy. In conclusion, the honeycomb carbon core represents a significant milestone in modern engineering and material science. Its implementation across various sectors underscores the importance of innovation driven by nature-inspired designs, professional expertise, and a commitment to sustainability. As we continue to push the boundaries of what’s possible, the honeycomb carbon core stands out as a testament to the ingenuity and potential that advanced materials bring to the table.

Prev:

Next:

Products categories

Latest news

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025

-

Revolutionizing Airflow and Protection with Stainless Steel Honeycomb PanelsNewsJun.10,2025

-

Precision Shielding and Structural Solutions with Honeycomb Plate TechnologyNewsJun.10,2025

-

Optimizing Airflow with Advanced Honeycomb Ventilation SolutionsNewsJun.10,2025

-

Optimizing Airflow and Testing Efficiency with Honeycomb TechnologyNewsJun.10,2025

-

Enhanced Turbine Efficiency with Sealed Honeycomb TechnologyNewsJun.10,2025

-

Engineering Excellence with Steel Honeycomb Core StructuresNewsJun.10,2025