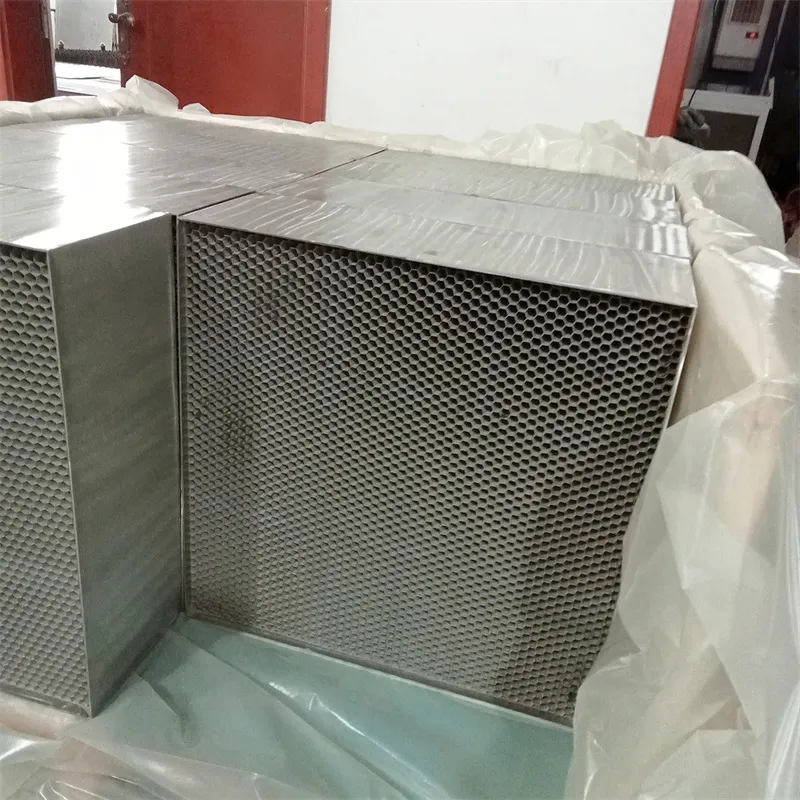

Hengshi Air Straightening Honeycomb for Wind Rectification in Aerospace and Aircraft Industries

This high-performance honeycomb structure ensures laminar airflow, reducing turbulence and optimizing aerodynamic testing environments. Engineered to meet the demanding requirements of the aerospace sector, our air straightening honeycomb plays a critical role in wind tunnels, aerodynamic research, and other high-precision applications.

1. Efficient Wind Rectification for Accurate Testing

Our honeycomb air straighteners are ideal for ensuring uniform airflow in wind tunnel setups and other aerospace testing environments:

- Turbulence Reduction: The honeycomb structure effectively minimizes air turbulence, straightening airflow to create a smooth, laminar stream. This allows for more accurate and consistent test results.

- Improved Aerodynamic Analysis: By promoting steady airflow, the honeycomb ensures that aerodynamic data collected during testing is precise, aiding in the optimization of aircraft designs and other aerospace components.

2. Durable and Lightweight Construction

Made from high-quality materials such as aluminum or stainless steel, the Hengshi air straightening honeycomb offers:

- High Strength-to-Weight Ratio: Lightweight yet incredibly strong, the honeycomb structure is built to withstand the intense conditions of aerospace testing without adding unnecessary weight to the wind tunnel setup.

- Corrosion Resistance: Both aluminum and stainless steel options offer superior resistance to corrosion, ensuring long-lasting performance in various testing environments.

- Temperature and Pressure Resistance: The honeycomb structure is capable of withstanding high-speed winds and extreme temperatures, maintaining its structural integrity throughout prolonged testing.

3. Customizable to Meet Specific Requirements

We offer fully customizable solutions to ensure that the Hengshi air straightening honeycomb meets your exact requirements:

- Custom Dimensions: Available in a wide range of sizes, thicknesses, and cell configurations to suit your wind tunnel setup or aerospace application.

- Tailored Material Options: Choose from aluminum, stainless steel, or other materials based on your specific needs for weight, strength, and environmental resistance.

- Custom Mounting Options: We offer various mounting and integration solutions to ensure seamless installation in your testing equipment or wind tunnel.

4. Applications in the Aerospace and Aircraft Industry

The Hengshi air straightening honeycomb is extensively used in the aerospace and aircraft industries for a variety of testing and manufacturing applications:

- Wind Tunnels: Essential for wind rectification in aerodynamic testing of aircraft components, from wings to fuselage, ensuring accurate and reliable data.

- Aircraft Manufacturing: Supports the development and optimization of aircraft designs, helping engineers refine aerodynamics for better fuel efficiency and performance.

- Spacecraft and Rocket Testing: Used in high-speed wind tunnels for simulating and testing spacecraft and rocket components under realistic conditions.

5. Why Choose Hengshi Air Straightening Honeycomb?

- Superior Airflow Management: Our honeycomb structures are engineered to provide smooth, laminar airflow, reducing turbulence and enhancing the precision of aerodynamic testing.

- Durable, High-Quality Materials: Made from corrosion-resistant and durable materials, our honeycomb ensures long-lasting performance, even in challenging environments.

- Fully Customizable: We offer tailored solutions to meet your specific testing needs, from material selection to custom sizing and mounting options.

- Proven Performance in Aerospace Applications: Trusted by aerospace and aircraft industries for precise wind rectification, the Hengshi honeycomb is a reliable solution for high-performance testing and development.

Contact us today to learn how the Hengshi Air Straightening Honeycomb can be customized for your aerospace or aircraft industry applications, providing effective wind rectification and enhanced aerodynamic testing!

Latest news