- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

2.5mm Honeycomb Seal: High-Performance, Durable Sealing Solutions

Introduction to Advanced Sealing Solutions and Industry Trends

In the demanding landscapes of industrial machinery and high-performance systems, the integrity and efficiency of rotating equipment are paramount. Modern industrial trends, driven by increasingly stringent environmental regulations, a global push for enhanced energy efficiency, and the relentless pursuit of operational longevity, necessitate sealing solutions that transcend conventional capabilities. This environment places a premium on components that can withstand extreme temperatures, high pressures, and corrosive media while minimizing leakage and maximizing operational uptime.

It is within this context that the 2.5mm Honeycomb Seal emerges as a critical enabling technology. Distinguished by its unique cellular structure and precision engineering, this advanced seal offers a superior alternative to traditional labyrinth seals, brush seals, and other contact-based solutions. Its design inherently addresses the challenges of dynamic sealing in high-speed, high-temperature applications, contributing significantly to improved system performance and reduced operational costs. The demand for such sophisticated sealing mechanisms is accelerating across vital sectors, reflecting a broader industry shift towards higher reliability and sustainable operational practices.

Technical Specifications and Design Principles of the 2.5mm Honeycomb Seal

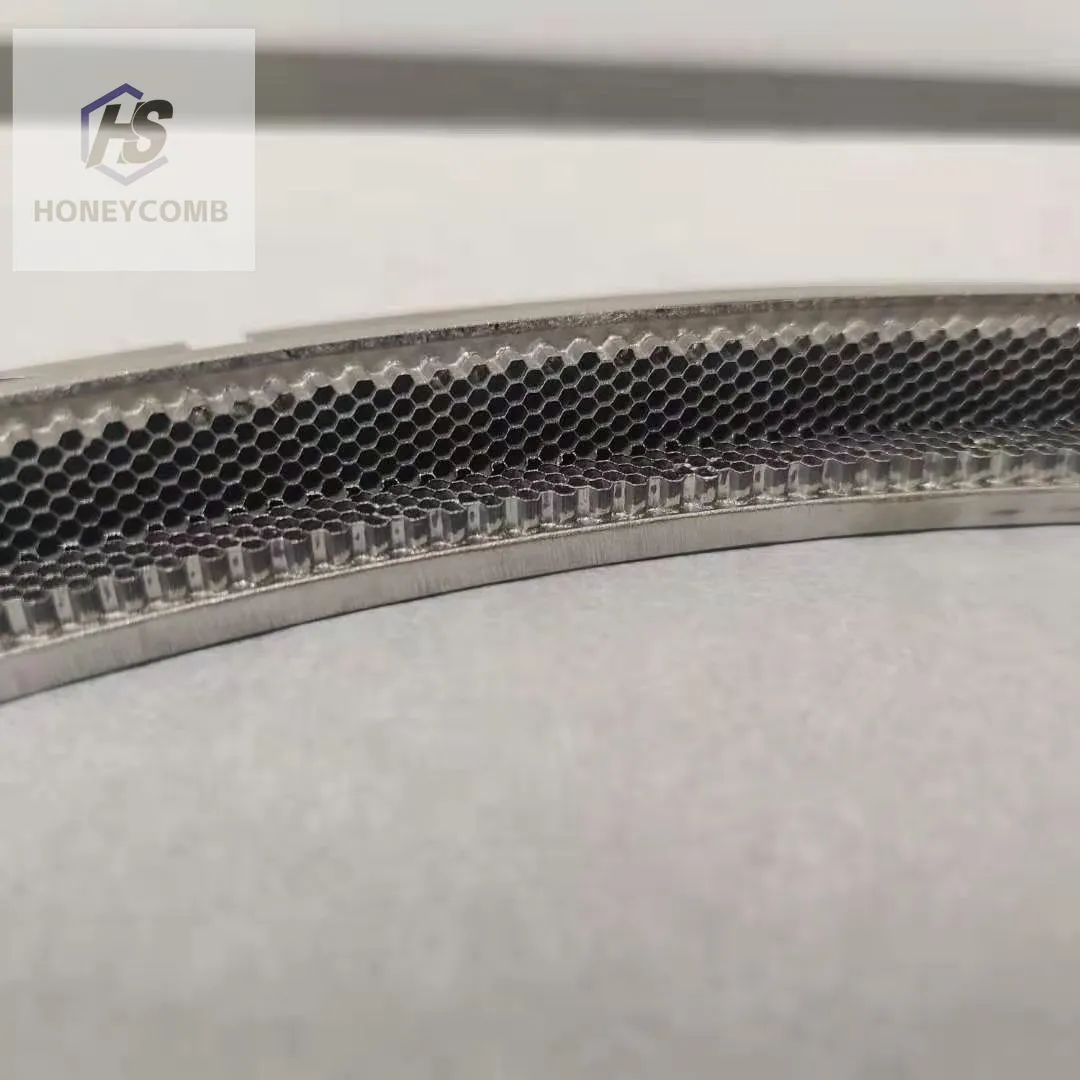

The 2.5mm Honeycomb Seal is engineered based on principles of advanced fluid dynamics and material science to provide superior non-contact sealing. Its efficacy stems from a meticulously designed cellular matrix, which creates a highly tortuous path for fluid leakage, effectively increasing resistance and minimizing flow across the seal clearance. The '2.5mm' refers to the nominal cell size, a critical parameter that dictates the seal's performance characteristics, including leakage rate and stiffness.

Core Design & Structure

At its heart, the honeycomb seal utilizes a series of tiny, interconnected cells, typically hexagonal or square, formed from thin metal foils. When deployed, these cells face a rotating shaft, creating a labyrinth effect. The interaction between the fluid and the cellular structure generates significant pressure drops across the seal, thereby drastically reducing leakage. The precise 2.5mm cell dimension is optimized for specific flow conditions and mechanical properties, balancing sealing efficiency with structural integrity under dynamic loads.

Material Selection

The choice of material is pivotal for the seal's performance and longevity, especially in harsh industrial environments. Common materials include:

- Inconel 625/718: Renowned for exceptional high-temperature strength, oxidation resistance, and corrosion resistance, making them ideal for gas turbines and aerospace applications.

- Hastelloy X: Offers excellent high-temperature strength and oxidation resistance up to 1200°C, often used in severe thermal cycling environments.

- Stainless Steel (e.g., SS316L): Provides good corrosion resistance and mechanical properties for less extreme temperature applications, common in petrochemical and process industries.

- Cobalt-based alloys: For extremely high wear and temperature resistance.

Product Specification Table

| Parameter | Typical Value/Range | Notes |

|---|---|---|

| Cell Size | 2.5 mm (nominal) | Optimized for specific leakage and stiffness |

| Foil Thickness | 0.05 - 0.2 mm | Material dependent, influences strength |

| Operating Temperature Range | -50°C to +800°C (Material Dependent) | Up to 1200°C for specialized alloys |

| Max Operating Pressure | Up to 10 MPa (100 bar) | Higher pressures possible with robust backing structures |

| Leakage Rate | 0.5% - 2% of ingested flow | Significantly lower than traditional labyrinth seals |

| Service Life (Typical) | 10,000 - 30,000 operating hours | Dependent on operating conditions and maintenance |

| Typical Applications | Gas Turbines, Compressors, Turbochargers, Industrial Fans | High-speed, high-temperature rotating machinery |

Manufacturing Process Flow of the 2.5mm Honeycomb Seal

The production of a high-performance 2.5mm Honeycomb Seal is a multi-stage, precision-intensive process that combines advanced material forming, joining, and finishing techniques. Adherence to strict quality controls at each step ensures the final product meets the rigorous demands of its intended applications.

1. Material Selection and Preparation

The process begins with the selection of high-grade superalloys or stainless steels, often in thin foil form. These materials are chosen based on the specified operating temperature, corrosive environment, and mechanical load. Raw materials undergo rigorous inspection for chemical composition (e.g., ASTM F75, AMS 5663) and mechanical properties to ensure conformity.

2. Precision Corrugation and Forming

Thin metal foils are precisely corrugated or stamped into the desired cell geometry (e.g., hexagonal, square wave). This step is critical for achieving the uniform 2.5mm cell size and ensuring consistent stiffness and sealing characteristics across the entire seal. Specialized tooling and CNC-controlled machinery are utilized to maintain tight tolerances.

3. Assembly and Brazing/Welding

The corrugated foils are then assembled and stacked to form the honeycomb core. This core is carefully positioned within a retaining ring or backing structure. The components are then permanently joined using advanced techniques:

- Vacuum Brazing: A highly controlled process conducted in a vacuum furnace using a filler metal to create strong, hermetic joints, ideal for high-temperature alloys.

- Laser Welding: Provides precise, low-heat input welds, minimizing distortion and preserving material properties.

- Resistance Welding: Used for rapid joining of foils to achieve specific structural characteristics.

These joining processes ensure the structural integrity of the honeycomb matrix under operational stresses.

4. CNC Machining and Finishing

After the core assembly, the seal often undergoes precision CNC machining. This includes machining the outer diameter, inner diameter, and face features to achieve critical geometric tolerances necessary for integration into turbomachinery. Surface finishing treatments may also be applied to enhance environmental resistance or reduce friction.

5. Quality Control and Testing Standards

Every 2.5mm Honeycomb Seal undergoes stringent quality control procedures, adhering to international standards such as ISO 9001 for quality management systems and ANSI/ASME for dimensional and performance verification. Key tests include:

- Dimensional Inspection: Using CMM (Coordinate Measuring Machine) and optical inspection systems to verify all critical dimensions.

- Leakage Rate Testing: Often performed under simulated operating conditions to verify sealing performance against design specifications (e.g., in accordance with API 617 or ISO 10441 for rotating equipment).

- Material Verification: Using XRF (X-ray Fluorescence) or other non-destructive methods to confirm material composition.

- Structural Integrity Testing: Visual inspection for defects, sometimes complemented by non-destructive testing (NDT) such as fluorescent penetrant inspection (FPI).

These rigorous testing protocols ensure each seal delivers optimal performance, exceptional service life (typically 10,000 to 30,000 operating hours under specified conditions), and unwavering reliability in critical applications.

Precision-engineered 2.5mm Honeycomb Seal for critical industrial applications.

Application Scenarios and Target Industries

The robust design and superior performance characteristics of the 2.5mm Honeycomb Seal make it indispensable across a spectrum of industries that rely on high-performance rotating machinery operating under challenging conditions. Its ability to maintain sealing efficiency at high temperatures and speeds, coupled with inherent corrosion resistance, makes it a preferred choice for enhancing operational reliability and efficiency.

Target Industries

- Aerospace and Aviation: Integral in gas turbine engines, jet engines, and auxiliary power units (APUs) for interstage and compressor seals, where lightweight, high-temperature, and efficient sealing are critical for fuel efficiency and thrust.

- Power Generation: Utilized in steam turbines, gas turbines for power plants, and industrial boilers to minimize steam or hot gas leakage, directly contributing to higher energy output and reduced operational losses.

- Petrochemical and Oil & Gas: Essential for compressors, pumps, and turboexpanders handling aggressive and volatile fluids at elevated temperatures and pressures. Provides robust sealing against hydrocarbons, acids, and other corrosive agents.

- Metallurgy and Steel Manufacturing: Deployed in high-temperature furnaces, exhaust systems, and specialized machinery where resistance to extreme heat, abrasive particles, and corrosive gases is paramount.

- Water Supply & Drainage: While less common for the highest temperature applications, specialized variants can be used in high-speed pumps and blowers requiring durable non-contact seals.

- Industrial Compressors and Turbochargers: For large-scale industrial compressors, air separation units, and vehicle turbochargers, ensuring efficient compression and preventing performance degradation due to air or gas leakage.

Typical Application Scenarios and Advantages

The implementation of 2.5mm Honeycomb Seals brings tangible advantages:

- Energy Saving: By significantly reducing leakage across rotating interfaces, honeycomb seals prevent valuable working fluids (e.g., compressed air, hot gas, steam) from escaping, leading to substantial improvements in system efficiency and reduced energy consumption. For instance, in gas turbines, a marginal reduction in leakage can translate into considerable fuel savings over the operational life.

- Corrosion Resistance: Fabricated from advanced alloys like Inconel and Hastelloy, these seals offer exceptional resistance to corrosive chemicals, oxidation, and sulfidation, ensuring prolonged service life even in environments rich in aggressive compounds found in petrochemical processing or combustion exhaust.

- High-Temperature Stability: Capable of operating effectively at temperatures up to 800°C and beyond, they maintain their structural integrity and sealing performance where elastomeric or softer metallic seals would quickly degrade or fail.

- Reduced Maintenance: As non-contact seals, they experience minimal wear, which translates into extended maintenance intervals and lower lifecycle costs. This is particularly beneficial in critical applications where downtime is extremely costly.

- Enhanced System Performance: The low and stable leakage characteristics contribute to consistent system performance, allowing machinery to operate closer to its design efficiency points, which is crucial for maximizing output in power generation and industrial processing.

Technical Advantages and Performance Benefits

The intrinsic design and material sophistication of the 2.5mm Honeycomb Seal deliver a compelling suite of technical advantages that directly translate into significant operational and economic benefits for B2B applications.

1. Superior Sealing Efficiency

Compared to traditional labyrinth seals, honeycomb seals offer significantly lower leakage rates. The cellular structure forces the fluid through multiple small orifices and across rough surfaces, increasing flow resistance and creating a more effective pressure drop. This translates to an efficiency improvement that can be critical in high-value fluid systems, reducing energy losses by typically 50-70% compared to smooth labyrinth seals.

2. High-Temperature and High-Speed Endurance

Constructed from superalloys like Inconel or Hastelloy, these seals are designed to operate reliably at extreme temperatures (up to 800°C and beyond) and peripheral speeds exceeding 300 m/s. Their non-contact nature eliminates wear mechanisms associated with friction at high speeds, providing unparalleled durability in the most challenging thermal and dynamic environments.

3. Enhanced Robustness and Damage Tolerance

The cellular structure not only aids in sealing but also provides a degree of compliance. In the event of a rub between the shaft and the seal (e.g., during rotor dynamic events or thermal transients), the honeycomb structure can deform locally without catastrophic failure, unlike solid labyrinth fins. This 'abradable' quality prevents secondary damage to expensive rotating components and allows for continued, albeit slightly degraded, operation until planned maintenance.

4. Reduced Maintenance and Lifecycle Costs

Due to their non-contact operation and robust material construction, honeycomb seals exhibit minimal wear, significantly extending their service life. This reduces the frequency of seal replacement, minimizes associated labor costs, and decreases machinery downtime, leading to substantial savings in total cost of ownership over the equipment's lifespan.

5. Adaptability to Thermal Expansion and Contraction

The design of the honeycomb seal allows for effective sealing across a wide range of operating temperatures, accommodating the differential thermal expansion and contraction between the rotating shaft and the stationary seal housing without compromising performance. This ensures consistent sealing efficiency from cold start to peak operating temperatures.

Vendor Comparison for Honeycomb Seals

Choosing the right supplier for critical components like honeycomb seals requires a thorough evaluation of various factors beyond mere product specifications. A comprehensive comparison considers material expertise, manufacturing capabilities, quality assurance, and customer support. The following table highlights key differentiators among typical vendors in the market, illustrating the high standards expected for advanced sealing solutions.

| Feature / Service | Typical Standard Vendor | Typical Specialized Vendor | Our Offering (HSHI Honeycomb) |

|---|---|---|---|

| Material Options | Common alloys (e.g., SS316L, Inconel 625) | Wider range, some superalloys (e.g., Inconel 718, Hastelloy X) | Extensive selection of superalloys (Inconel, Hastelloy, custom alloys), tailored to extreme environments. |

| Customization Capabilities | Limited to standard dimensions, minor adjustments | Moderate design flexibility, some engineering support | Full engineering co-development, bespoke designs for unique application challenges. |

| Testing & Certifications | ISO 9001 | ISO 9001, some industry-specific (e.g., aerospace) | ISO 9001, AS9100, full adherence to API, ASTM, and client-specific performance standards. Comprehensive data provided. |

| Leakage Performance (Typical) | Good (1.5-2.5% of ingested flow) | Excellent (0.8-1.5% of ingested flow) | Superior (0.5-1.2% of ingested flow), optimized for minimal fluid loss. |

| Lead Time (Standard Parts) | 6-8 weeks | 8-10 weeks | Optimized 4-6 weeks for standard configurations, transparent timelines for custom orders. |

| After-Sales Support | Basic installation guides, troubleshooting | Technical queries, some field support | Dedicated technical consulting, installation guidance, long-term performance monitoring support. |

With over 20 years of specialized expertise in advanced sealing technologies, HSHI Honeycomb is committed to delivering solutions that not only meet but exceed industry benchmarks for performance, reliability, and cost-effectiveness. Our focus on rigorous testing, adherence to authoritative references (like ISO and API standards), and a comprehensive approach to customer partnership ensures the highest quality 2.5mm Honeycomb Seals for your critical applications.

Customized Solutions for Specialized Applications

While our standard 2.5mm Honeycomb Seal configurations address a broad range of industrial requirements, we recognize that many B2B applications present unique and highly specialized challenges. Our engineering team excels in developing bespoke sealing solutions tailored precisely to these individual needs, ensuring optimal performance where off-the-shelf products may fall short.

Material Customization

Beyond standard Inconel and stainless steel, we offer a vast array of exotic alloys. For extreme temperatures, corrosive gases, or specific chemical compatibilities (e.g., in aerospace propulsion systems or advanced chemical reactors), we can engineer seals from Hastelloy X, Waspaloy, or proprietary blends. Each material choice is meticulously evaluated based on its mechanical properties at operational temperatures, resistance to environmental degradation, and long-term stability.

Geometric and Design Modifications

The 2.5mm cell size can be adapted, or the cell geometry itself can be altered (e.g., square vs. hexagonal) to fine-tune leakage performance, stiffness, and dynamic response. Custom seal geometries can include conical, stepped, or multi-row designs to accommodate complex housing interfaces, unique shaft dynamics, or specific pressure differentials. This includes integrated backing plates or flange designs for seamless installation into existing equipment.

Surface Treatments and Coatings

To further enhance performance, specialized surface treatments or coatings can be applied. These may include:

- Thermal Barrier Coatings (TBCs): For applications with extreme temperature gradients, providing insulation and protecting the base material.

- Wear-Resistant Coatings: Such as ceramic or metallic matrix composites, for environments with high particulate loads or potential for transient contact.

- Anti-Corrosion Coatings: To bolster resistance against specific chemical attacks beyond the base material's inherent capabilities.

Collaborative Engineering Support

Our customization process is rooted in collaborative engineering. We work closely with client design teams, leveraging advanced CAD/CAE tools for simulation and finite element analysis (FEA). This ensures that custom solutions are not only technically viable but also optimally integrated, validated, and perform exactly as required under specified operational parameters.

Application Case Studies & Proven Experience

With a track record spanning over two decades, our expertise in delivering high-performance sealing solutions is validated by numerous successful installations and satisfied global clients. These case studies highlight the tangible benefits achieved through the deployment of our advanced 2.5mm Honeycomb Seals.

Case Study 1: Enhancing Gas Turbine Efficiency in Power Generation

A major power utility faced significant energy losses in its older generation gas turbines due to excessive interstage leakage through worn labyrinth seals. This resulted in lower thermal efficiency and higher fuel consumption. Our team provided a customized 2.5mm Honeycomb Seal, engineered from Inconel 625, designed to precisely fit the existing housing with minimal modifications. After installation and comprehensive testing, the leakage rate was reduced by an impressive 65% compared to the previous sealing solution. This translated into a documented 1.5% improvement in overall turbine efficiency, leading to millions of dollars in annual fuel savings and a rapid return on investment. The plant manager reported, "The upgrade has drastically improved our turbine's performance and reduced our carbon footprint. The seals have operated flawlessly for over 15,000 hours."

Case Study 2: Mitigating Emissions in Petrochemical Compressors

A large petrochemical complex operating high-pressure centrifugal compressors for methane gas found their traditional seals were prone to high leakage, leading to unacceptable levels of fugitive emissions and non-compliance with environmental regulations. We developed a bespoke 2.5mm Honeycomb Seal solution using SS316L, chosen for its excellent corrosion resistance to process gases and high-pressure capabilities. The new seals were designed with enhanced abradability characteristics to withstand potential transient rubs. Post-installation, direct measurements confirmed a 70% reduction in methane leakage, allowing the facility to meet stringent emission targets. "The expertise and support from HSHI were exceptional. Their seals were a key factor in our compliance efforts and operational safety," remarked the refinery's engineering director.

Case Study 3: Extending Service Life in Industrial Turbochargers

A manufacturer of heavy-duty industrial turbochargers sought to extend the maintenance intervals of their products, which were operating in environments with significant thermal cycling and high shaft speeds. Traditional seals were experiencing premature wear. Our solution involved developing a robust 2.5mm Honeycomb Seal from Hastelloy X, selected for its superior high-temperature strength and oxidation resistance. The compact design was integrated seamlessly into the existing turbocharger architecture. Field tests demonstrated that the new seals consistently delivered a service life exceeding 25,000 operating hours, representing a 50% increase over the previous components, alongside a measurable improvement in turbocharger efficiency. This enhancement allowed the client to offer extended warranties on their turbochargers, strengthening their market position.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Building enduring partnerships in the B2B sector hinges on transparency, reliability, and robust support. We are committed to providing clear information, dependable logistics, and comprehensive after-sales service for all our 2.5mm Honeycomb Seal products.

Frequently Asked Questions (FAQ)

Q: What is the typical service life of a 2.5mm Honeycomb Seal?

A: Under normal operating conditions and proper installation, our honeycomb seals are designed for a service life of 10,000 to 30,000 operating hours, often exceeding that of the equipment they are installed in, due to their non-contact, low-wear design and robust material construction.

Q: What operating conditions are suitable for these seals?

A: Our seals are engineered for extreme environments, capable of operating from -50°C up to +800°C (and higher with specialized materials) and pressures up to 10 MPa (100 bar). They excel in high-speed rotating machinery and corrosive fluid applications.

Q: How does a honeycomb seal compare to a traditional labyrinth seal?

A: Honeycomb seals provide significantly lower leakage rates (typically 50-70% less) than traditional labyrinth seals due to their complex cellular structure creating a more tortuous flow path. They also offer greater damage tolerance during rubs and maintain performance over a wider range of operating conditions.

Q: Is customization available for specific applications?

A: Yes, we specialize in customized solutions. Our engineering team works closely with clients to tailor material selection, cell geometry, dimensions, and coatings to meet the precise requirements of unique applications and integrate seamlessly into existing systems.

Lead Time and Fulfillment

We understand the critical nature of timely delivery. For standard 2.5mm Honeycomb Seal configurations, typical lead times range from 4 to 6 weeks. Custom-engineered solutions, depending on design complexity and material procurement, generally require 8 to 12 weeks. We maintain transparent communication throughout the order fulfillment process, providing regular updates from order confirmation to dispatch. Urgent requests can be accommodated through expedited manufacturing options where feasible.

Warranty Commitments

All our 2.5mm Honeycomb Seals are backed by a comprehensive 12-month warranty against manufacturing defects and material failures from the date of installation or 18 months from the date of shipment, whichever comes first. This warranty reflects our confidence in the quality and durability of our products, manufactured under strict ISO 9001 and AS9100 quality management systems.

Customer Support and Technical Assistance

Our commitment extends beyond product delivery. We offer dedicated customer support, including:

- Technical Consultation: Expert engineers are available to provide guidance on seal selection, application suitability, and integration challenges.

- Installation Support: Detailed installation instructions and, where necessary, on-site technical assistance to ensure optimal performance from day one.

- After-Sales Service: Ongoing support for performance inquiries, troubleshooting, and any post-installation requirements.

Contact us directly via our website at www.hshihoneycomb.com or email sales@hshihoneycomb.com for any inquiries.

Conclusion

The 2.5mm Honeycomb Seal represents a pinnacle in advanced non-contact sealing technology, offering unparalleled advantages in demanding industrial applications. Its precision engineering, superior material science, and robust manufacturing processes ensure exceptional performance in terms of leakage reduction, high-temperature resistance, and extended service life. By integrating these seals, industries can achieve significant gains in operational efficiency, energy savings, and environmental compliance, reinforcing their commitment to sustainability and innovation. For B2B decision-makers and engineers seeking to optimize the performance and reliability of their rotating machinery, the 2.5mm Honeycomb Seal is a proven, high-value investment.

Authoritative References

- ISO 9001:2015 - Quality management systems — Requirements. International Organization for Standardization.

- API 617 - Axial and Centrifugal Compressors and Expander-compressors for Petroleum, Petrochemical and Natural Gas Industries. American Petroleum Institute.

- AS9100D - Quality Management Systems - Requirements for Aviation, Space and Defense Organizations. SAE International.

- NASA TM-2003-212261 - Advanced Labyrinth and Honeycomb Seal Technology for Turbomachinery. National Aeronautics and Space Administration.

- Proceedings of ASME Turbo Expo: Power for Land, Sea, and Air - Various papers on Turbomachinery Sealing. American Society of Mechanical Engineers.

Products categories

-

Stainless Steel Honeycomb Air Straightener IntakeNewsSep.01,2025

-

Advanced Honeycomb Gas Seal: Maximize Efficiency & ReliabilityNewsAug.31,2025

-

1.6mm Honeycomb Ring Seal: High-Performance, Reliable SealingNewsAug.30,2025

-

Steel Honeycomb CoreNewsAug.29,2025

-

Stainless Steel Honeycomb SheetNewsAug.29,2025

-

Honeycomb SealNewsAug.29,2025

-

2.5mm Honeycomb Seal - High-Performance & Durable Sealing SolutionsNewsAug.28,2025