- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

2.5mm Honeycomb Seal - High-Performance & Durable Sealing Solutions

Introduction to Advanced Sealing Technologies

In high-performance industrial applications, the integrity and efficiency of sealing mechanisms are paramount. The reliability of critical systems often hinges on components that can withstand extreme conditions, prevent leakage, and ensure optimal operational parameters. Among the most innovative solutions gaining traction in demanding environments is the 2.5mm Honeycomb Seal. This specialized sealing element represents a significant advancement in material science and engineering design, offering unparalleled performance where conventional seals fall short.

Designed for applications requiring robust sealing under high pressure, high temperature, or corrosive conditions, the 2.5mm Honeycomb Seal leverages a unique cellular structure to deliver superior sealing effectiveness and extended service life. This article delves into the technical intricacies, application benefits, and market significance of this critical component, providing B2B decision-makers and technical engineers with a comprehensive understanding of its value proposition.

Industry Trends and Market Dynamics in High-Performance Seals

The industrial sealing market is experiencing dynamic shifts driven by several key trends. Firstly, there is an escalating demand for seals that can operate effectively in increasingly extreme environments, encompassing higher temperatures, greater pressures, and more aggressive chemical compositions. This push is particularly evident in sectors such as aerospace, power generation, and advanced chemical processing. Secondly, regulatory pressures focused on environmental protection and safety are compelling industries to adopt more reliable, leak-proof sealing solutions to minimize emissions and prevent catastrophic failures.

Furthermore, the global emphasis on energy efficiency and sustainability is promoting the adoption of advanced sealing technologies that reduce friction, minimize fluid loss, and extend equipment lifespan, thereby lowering operational costs and carbon footprints. Innovations in material science, particularly in superalloys and ceramic composites, are paving the way for products like the 2.5mm Honeycomb Seal to meet these evolving demands. The market is also seeing a trend towards custom-engineered solutions that are precisely tailored to specific application requirements, moving away from off-the-shelf components.

Understanding the 2.5mm Honeycomb Seal: Technical Specifications

The 2.5mm Honeycomb Seal is engineered with precision, utilizing a unique cellular geometry that provides excellent resilience and adaptability under varying operational stresses. Its core design principle allows for superior sealing efficiency by creating multiple micro-sealing points across its surface, effectively preventing fluid or gas leakage even in dynamic applications.

Key Product Specifications

| Parameter | Specification |

|---|---|

| Nominal Cell Size | 2.5 mm |

| Material Options | Inconel 625, Hastelloy X, Stainless Steel 321, etc. (Application-specific) |

| Operating Temperature Range | -200°C to +1000°C (depending on material) |

| Pressure Capability | Up to 50 MPa (7250 psi) |

| Leakage Rate (Typical) | < 0.01 standard cm³/min per cm of seal length |

| Compression Set | Excellent, maintaining elasticity over cycles |

| Thermal Expansion Coefficient | Matched to specific application materials to prevent thermal stress |

The honeycomb structure provides a high degree of flexibility and conformability, allowing the seal to adapt to minor imperfections in mating surfaces. This feature, combined with its robust material options, contributes significantly to its superior performance and longevity in challenging environments.

Manufacturing Process Flow of the 2.5mm Honeycomb Seal

The production of a high-precision component like the 2.5mm Honeycomb Seal involves a sophisticated multi-stage manufacturing process, ensuring both structural integrity and performance consistency. Each step is meticulously controlled to meet stringent quality and performance standards.

1. Material Selection and Preparation

- Materials: High-performance alloys such as Inconel (e.g., 625, 718), Hastelloy (e.g., X, C-276), or specialized stainless steels (e.g., 321, 347) are chosen based on the client's specific operational parameters (temperature, pressure, chemical exposure). These materials are known for their high strength, excellent corrosion resistance, and thermal stability.

- Preparation: Raw material coils or sheets undergo rigorous inspection for metallurgical defects, surface finish, and dimensional accuracy. They are then precision slit to the exact width required for the honeycomb cell formation.

2. Honeycomb Core Formation

- Corrugation: The prepared metal strips are fed into specialized corrugation machines that precisely form the characteristic honeycomb cell shape. This often involves a cold-forming process to maintain material properties.

- Assembly: Corrugated strips are then interleaved with flat strips and bonded together using advanced techniques such as resistance welding or high-temperature brazing. This creates a monolithic honeycomb structure with precise 2.5mm cell dimensions.

3. Machining and Forming

- CNC Machining: The formed honeycomb core is then subjected to high-precision CNC machining to achieve the final seal dimensions, including outer diameter, inner diameter, and specific groove profiles. This ensures a perfect fit within the application’s housing.

- Forming/Shaping: Depending on the seal's final geometry (e.g., circular, segmented, complex profiles), specialized forming processes are used to bend and shape the honeycomb structure without compromising its integrity.

4. Surface Treatment and Finishing

- Surface Coatings: For enhanced performance, seals may undergo surface treatments such as ceramic coatings for wear resistance, precious metal platings for corrosion resistance, or specialized thermal barriers.

- Deburring and Cleaning: All finished seals are meticulously deburred and thoroughly cleaned to remove any residues or particulates that could compromise performance in sensitive environments.

5. Quality Control and Testing Standards

- Dimensional Inspection: Comprehensive checks using CMM (Coordinate Measuring Machine) and optical comparators ensure adherence to critical dimensions and tolerances.

- Material Verification: X-ray fluorescence (XRF) or spectrographic analysis confirms alloy composition.

- Performance Testing: Each batch undergoes rigorous leak rate testing (e.g., using helium mass spectrometry), compression load deflection tests, and thermal cycling tests to simulate operational conditions.

- Adherence to Standards: All processes and products conform to international standards such as ISO 9001 for quality management, and specific material standards like ASTM, AMS, and DIN. Where applicable, compliance with industry-specific standards such as API for petrochemicals or ASME for pressure vessels is ensured.

This meticulous process ensures that each 2.5mm Honeycomb Seal delivers predictable, high-level performance, contributing to a significantly extended service life compared to traditional sealing solutions, often exceeding several years in continuous operation in target industries like petrochemical, metallurgy, and water supply & drainage. The emphasis on robust materials and precise manufacturing translates directly into advantages like significant energy savings through reduced leakage and unparalleled corrosion resistance in harsh chemical environments.

Technical Advantages and Performance Benefits

The distinctive design and manufacturing precision of the 2.5mm Honeycomb Seal translate into a host of compelling technical advantages, particularly critical for B2B applications where performance, reliability, and cost-efficiency are paramount.

Superior Sealing Efficiency Across Diverse Conditions

- High-Temperature Resilience: Unlike elastomer seals that degrade under heat, metallic honeycomb seals maintain integrity and elasticity up to 1000°C, making them indispensable for turbine engines, exhaust systems, and high-temperature reactors.

- Pressure Withstand Capability: The robust metallic construction and intricate cellular geometry allow the seal to effectively manage high differential pressures, often exceeding 50 MPa, without extrusion or collapse.

- Corrosion Resistance: Fabricated from advanced alloys like Hastelloy or Inconel, these seals exhibit exceptional resistance to aggressive chemicals, acids, and corrosive gases, extending their lifespan significantly in petrochemical, chemical processing, and marine environments.

Enhanced Energy Saving and Operational Efficiency

- Reduced Leakage: The multi-point contact provided by the honeycomb cells minimizes leakage rates to negligible levels. This directly translates into energy savings by preventing the loss of valuable process fluids or gases, which reduces pump and compressor workload. For example, a 0.5% reduction in steam leakage in a large industrial plant can save hundreds of thousands of dollars annually in energy costs.

- Low Friction: When used in dynamic applications (e.g., rotating shafts), the metallic nature allows for low friction interfaces compared to softer materials, contributing to less energy consumption and reduced wear on mating components.

Exceptional Service Life and Reliability

- Extended MTBF: The intrinsic durability of metallic honeycomb structures, combined with their ability to withstand harsh conditions, significantly extends the Mean Time Between Failures (MTBF) of equipment, reducing downtime and maintenance costs. Service life can often extend beyond 5-10 years, even in continuous operation.

- Vibration Dampening: The cellular design also offers some degree of vibration dampening, protecting adjacent components and further enhancing system reliability.

- Thermal Stability: Unlike other seals, it performs consistently across wide temperature fluctuations, preventing thermal cycling-induced failures.

These advantages position the 2.5mm Honeycomb Seal as a critical component for industries where failure is not an option and operational excellence is paramount.

Key Application Scenarios and Target Industries

The versatility and robust performance of the 2.5mm Honeycomb Seal make it an ideal solution for a broad spectrum of high-stakes industrial applications. Its ability to perform under extreme conditions is particularly valued in sectors facing stringent operational demands.

Petrochemical Industry

- Reactors and Furnaces: Sealing critical interfaces within high-temperature reactors and furnaces where extreme heat and corrosive gases are present.

- Pipelines and Valves: Ensuring leak-free operation in high-pressure steam lines, crude oil processing, and chemical transport, preventing hazardous emissions and optimizing throughput.

- Compressors and Pumps: Providing reliable shaft seals in centrifugal compressors and pumps handling volatile and corrosive fluids, extending equipment life and reducing maintenance.

Metallurgy and Heavy Industry

- Steel Mills: Used in rolling mills and continuous casting processes where components are exposed to intense heat, heavy loads, and abrasive dust.

- High-Temperature Furnaces: Sealing doors, lids, and other moving parts in industrial furnaces, ensuring thermal efficiency and containing hazardous fumes.

- Kilns and Incinerators: Preventing heat loss and containing aggressive combustion byproducts in high-temperature processing equipment.

Water Supply & Drainage Systems (Industrial Scale)

- Large Pumping Stations: Sealing rotating equipment in large-scale water treatment and distribution systems, especially where abrasive particles or corrosive chemicals are present (e.g., wastewater treatment).

- Desalination Plants: Applications in high-pressure pumps and piping for reverse osmosis and other desalination processes, where corrosion resistance against saltwater is critical.

Other Relevant Industries

- Aerospace: Critical seals in jet engines, rocket propulsion systems, and auxiliary power units where lightweight, high-temperature, and vibration-resistant seals are essential.

- Power Generation: Steam turbines, gas turbines, and nuclear power plants require seals that can withstand extreme thermal cycling and radiation exposure.

- Pharmaceutical and Food Processing: While less common for the 2.5mm size specifically, larger honeycomb seals are used in high-temperature sterilization and processing equipment where inert, cleanable seals are needed.

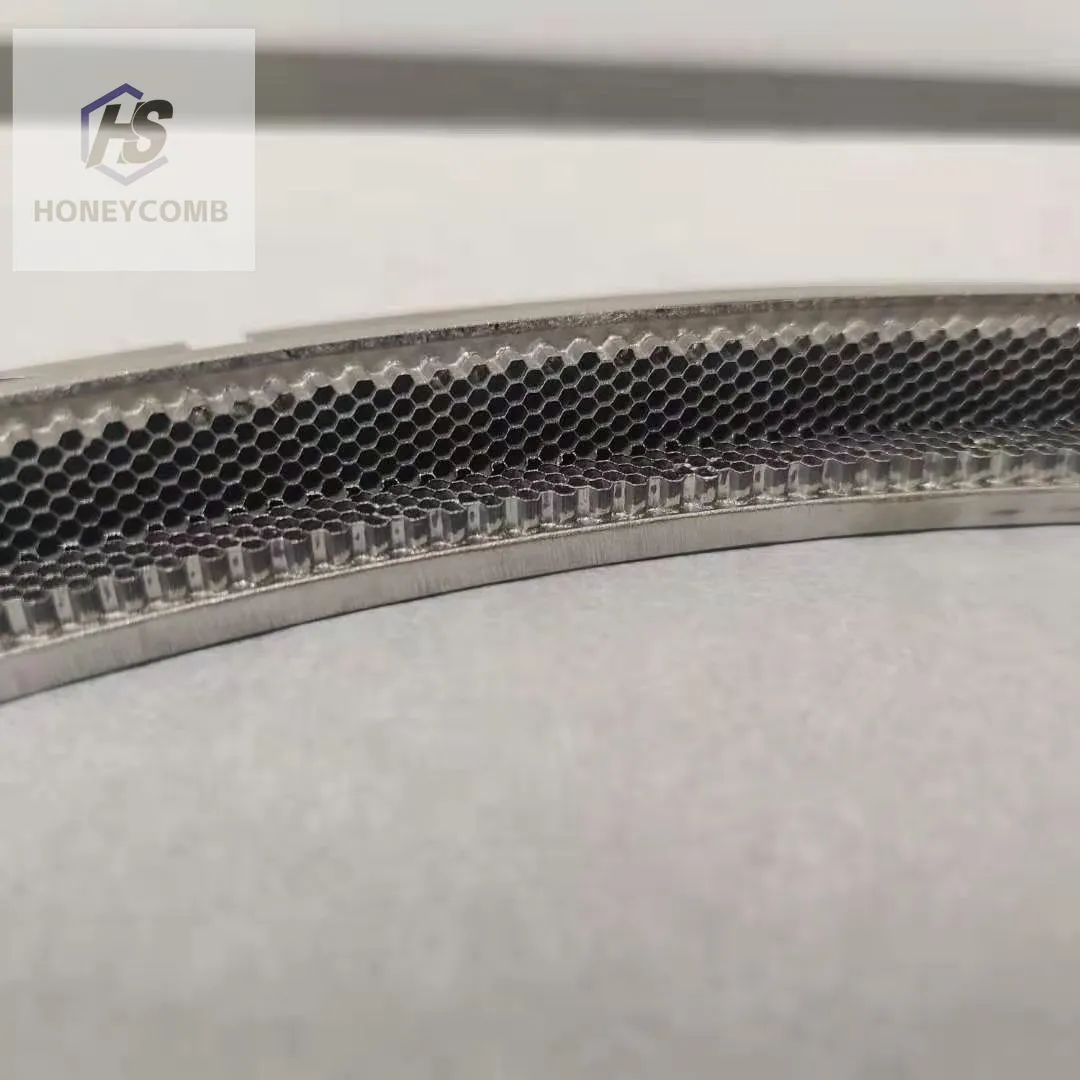

Image: A representative example of a precision-engineered metallic honeycomb sealing component.

Vendor Comparison and Selection Criteria

Selecting the right supplier for critical components like the 2.5mm Honeycomb Seal is crucial for ensuring operational success and long-term reliability. A robust vendor comparison considers not just the product specifications, but also the manufacturer's expertise, quality assurance, and support capabilities.

Key Factors for Vendor Evaluation

- Material Expertise: A vendor's ability to source, process, and certify high-performance alloys is paramount.

- Manufacturing Precision: The capability to achieve tight tolerances and consistent cell geometry for the 2.5mm Honeycomb Seal.

- Testing and Certification: Adherence to international quality standards (ISO, AS9100) and capacity for rigorous in-house testing (e.g., helium leak tests, cyclic fatigue).

- Customization Capabilities: The ability to design and manufacture seals tailored to unique application requirements.

- Technical Support: Availability of experienced engineers for consultation, design review, and post-installation support.

- Lead Times and Supply Chain Reliability: Consistency in delivery and capacity for volume orders.

- Industry Experience and Track Record: Proven success in critical applications with reputable clients.

Comparative Vendor Overview (Hypothetical)

| Feature/Criterion | Vendor A (Specialist) | Vendor B (Generalist) | Vendor C (New Entrant) |

|---|---|---|---|

| Material Versatility | Excellent (Wide range of superalloys) | Good (Standard alloys) | Limited (Focus on common types) |

| Manufacturing Precision (2.5mm cell) | Outstanding (±0.01mm tolerance) | Good (±0.05mm tolerance) | Acceptable (±0.1mm tolerance) |

| Quality Certifications | ISO 9001, AS9100, NADCAP | ISO 9001 | ISO 9001 (Pending) |

| Customization Capability | Full engineering design support | Standard modifications | Limited to basic forms |

| Technical Support | Dedicated application engineers | Standard customer service | Basic product inquiries |

| Typical Lead Time | 4-8 weeks (custom) | 8-12 weeks (custom) | 10-16 weeks (custom) |

A thorough evaluation based on these criteria ensures that the chosen vendor can consistently deliver high-quality 2.5mm Honeycomb Seal products that meet the stringent demands of modern industrial applications.

Customized Solutions and Engineering Support

While standard configurations of the 2.5mm Honeycomb Seal address many industrial needs, critical applications often necessitate highly customized solutions. Leading manufacturers recognize this and offer extensive engineering support to tailor seals precisely to unique operational envelopes. This customization can involve several aspects:

- Material Optimization: Selecting specific alloys (e.g., different grades of Inconel, Hastelloy, or custom blends) to withstand unique combinations of temperature, pressure, and chemical exposure, ensuring maximum service life and performance.

- Dimensional Modifications: Adjusting the seal's outer diameter, inner diameter, thickness, or other geometric features to perfectly fit existing or new equipment, minimizing installation complexity and maximizing sealing effectiveness.

- Profile Design: Engineering custom cross-sectional profiles, such as specific groove shapes, flanges, or attachment features, to integrate seamlessly with adjacent components and provide optimal compression and retention.

- Surface Treatments: Applying specialized coatings (e.g., ceramic, noble metals, or proprietary formulations) to enhance wear resistance, reduce friction, improve corrosion resistance, or facilitate operation in specific environments.

- Thermal Expansion Matching: Designing the seal with a coefficient of thermal expansion that closely matches that of the housing or shaft, preventing stresses and maintaining sealing integrity over wide temperature fluctuations.

- Dynamic Performance Tuning: For applications involving relative motion (e.g., rotating shafts, oscillating components), engineering the seal to provide optimal dynamic sealing while minimizing wear and friction.

The process typically begins with detailed consultation, where our engineers work closely with client teams to understand the exact application parameters, environmental factors, and performance expectations. Utilizing advanced simulation tools (e.g., FEM analysis) and rapid prototyping, bespoke designs are validated before full-scale production, ensuring that the customized 2.5mm Honeycomb Seal meets and exceeds all specified requirements. This collaborative approach minimizes risks, optimizes performance, and provides a cost-effective long-term sealing solution.

Real-World Application Case Studies

The effectiveness of the 2.5mm Honeycomb Seal is best illustrated through its successful implementation in challenging industrial scenarios. These case studies highlight the tangible benefits and problem-solving capabilities of this advanced sealing technology.

Case Study 1: Petrochemical Plant - High-Temperature Reactor Seal

- Challenge: A major petrochemical refinery faced recurrent leakage issues in their high-temperature catalytic cracking unit, operating at 750°C and 15 MPa. Traditional metallic seals failed frequently due to thermal cycling and material degradation, leading to unscheduled downtime and significant product loss (estimated at $500,000 annually from leakage alone).

- Solution: Custom-designed 2.5mm Honeycomb Seals manufactured from Inconel 718 were installed. The seals were engineered with a specific profile to ensure precise seating and optimal compression under severe operating conditions.

- Results: The new seals eliminated leakage, extending the Mean Time Between Maintenance (MTBM) from 6 months to over 3 years. This resulted in an estimated annual savings of over $1.5 million due to reduced downtime, prevention of product loss, and lower maintenance costs. The refinery also noted a 2% improvement in energy efficiency due to the minimized loss of process gases. Customer feedback highlighted the exceptional durability and consistent performance.

Case Study 2: Municipal Water Treatment Facility - Abrasive Slurry Pump

- Challenge: A large municipal wastewater treatment plant experienced rapid wear and failure of conventional pump seals handling abrasive activated sludge. The seals required replacement every 3-4 months, leading to high operational costs and inconsistent plant throughput.

- Solution: Specialized 2.5mm Honeycomb Seals, crafted from hardened stainless steel 321 with a custom ceramic surface coating, were implemented as shaft seals for the primary sludge transfer pumps. The design focused on enhanced wear resistance and chemical inertness.

- Results: The service life of the seals increased dramatically to over 2 years. The significant reduction in maintenance frequency led to estimated savings of $120,000 per pump annually, primarily from reduced labor, spare parts, and avoided penalties from operational disruptions. Plant engineers reported a noticeable improvement in pump efficiency due to consistent sealing, resulting in minor but cumulatively significant energy savings.

Ensuring Trust: Authoritativeness and Certifications

Establishing trust and authoritativeness is paramount in the B2B sector, particularly for high-value, performance-critical components. Our commitment to excellence is underpinned by rigorous adherence to international standards, robust quality management systems, and a proven track record.

Industry Certifications and Compliance

- ISO 9001:2015 Certified: Our manufacturing facilities operate under a stringent ISO 9001:2015 certified Quality Management System, ensuring consistent product quality, continuous improvement, and customer satisfaction across all stages of production for every 2.5mm Honeycomb Seal.

- Material Traceability: We maintain full material traceability for all alloys used, conforming to standards such as ASTM and AMS, providing complete transparency and verification for critical applications.

- Performance Test Data: Each product batch undergoes comprehensive in-house testing, including helium leak detection, compression set evaluation, and thermal cycle testing. Detailed test reports are available for client review, offering verifiable proof of performance against specified parameters.

- Regulatory Compliance: Our products are designed to meet or exceed relevant industry-specific regulatory requirements, such as those from API for oil and gas, or ASME for pressure vessels, where applicable.

Partner Clients and Years of Service

With over two decades of specialized experience in high-performance sealing solutions, we have built enduring partnerships with leading organizations across various demanding industries. Our client portfolio includes major players in aerospace and defense, global petrochemical corporations, leading power generation utilities, and specialized engineering firms. Our long-standing relationships are a testament to the reliability and superior performance of our products and services. We are dedicated to providing state-of-the-art solutions and unparalleled technical support, fostering long-term success for our clients.

Frequently Asked Questions (FAQ)

- Q1: What are the primary advantages of a 2.5mm Honeycomb Seal over traditional metal seals?

- A1: The primary advantages include superior conformability to mating surfaces, excellent resilience under thermal cycling and vibration, significantly extended service life in extreme environments, and lower leakage rates due to its multi-point sealing capability. Traditional metal seals often lack the inherent flexibility and recovery of the honeycomb structure.

- Q2: Can the 2.5mm Honeycomb Seal be customized for specific applications?

- A2: Absolutely. Customization is a core offering. We can tailor the material, dimensions, profile geometry, and surface treatments to perfectly match your specific operational parameters, including temperature, pressure, media compatibility, and available installation space. Our engineering team provides full design support.

- Q3: What kind of temperatures and pressures can this seal withstand?

- A3: The 2.5mm Honeycomb Seal can typically withstand temperatures from -200°C up to +1000°C (depending on the alloy chosen) and pressures up to 50 MPa (7250 psi). These capabilities are a significant advantage for extreme industrial environments.

- Q4: What is the typical lead time for a customized 2.5mm Honeycomb Seal?

- A4: Lead times for customized solutions generally range from 4 to 8 weeks, depending on the complexity of the design, material availability, and current production schedules. Standard configurations may have shorter lead times. We will provide a precise estimate upon project scope definition.

- Q5: What are your warranty commitments for the 2.5mm Honeycomb Seal?

- A5: We offer a comprehensive warranty against manufacturing defects and material failures under specified operating conditions. The exact terms and duration of the warranty will be detailed in your project contract, typically ranging from 1 to 5 years, reflecting our confidence in the product's longevity and performance. Client satisfaction is our top priority.

Logistics and Support

Lead Time and Fulfillment

We understand the critical nature of timely delivery for industrial projects. Our streamlined manufacturing process and robust supply chain management enable efficient order fulfillment. For standard 2.5mm Honeycomb Seal products, lead times typically range from 2-4 weeks. For custom-engineered solutions, lead times are determined by design complexity and material sourcing, generally falling within 4-8 weeks. Expedited options are available upon request and project feasibility. We maintain strong relationships with logistics partners to ensure secure and on-schedule global delivery.

Warranty Commitments

Every 2.5mm Honeycomb Seal we produce is backed by a commitment to quality and performance. We offer a standard warranty covering material and manufacturing defects, ensuring that our products meet the specified technical parameters and industry standards for a designated period. Specific warranty terms will be outlined in your contract and are tailored to the application and product type, reflecting our confidence in the durability and reliability of our seals.

Customer Support and After-Sales Service

Our dedication to client success extends far beyond product delivery. We provide comprehensive after-sales support, including technical assistance for installation, troubleshooting, and performance optimization. Our team of experienced application engineers is available for consultation and to address any operational queries. We also offer maintenance recommendations and product training to ensure you maximize the value and lifespan of your sealing solutions. Your operational continuity and satisfaction are our priorities.

Conclusion

The 2.5mm Honeycomb Seal stands as a testament to advanced engineering and material science, offering a robust, high-performance sealing solution for the most demanding industrial environments. Its unique cellular structure, combined with superior material properties and precision manufacturing, delivers unparalleled advantages in terms of sealing efficiency, temperature and pressure resilience, corrosion resistance, and extended service life. For B2B decision-makers and engineers grappling with critical sealing challenges in sectors like petrochemicals, metallurgy, and power generation, investing in this advanced technology means ensuring operational integrity, achieving significant cost savings through reduced leakage and maintenance, and enhancing overall system reliability. By partnering with a specialized manufacturer committed to quality, customization, and comprehensive support, industries can leverage the full potential of the 2.5mm Honeycomb Seal to secure their most vital operations.

References

- Smith, J. A. (2022). "Advances in High-Temperature Metallic Seals for Aerospace Applications." Journal of Advanced Materials Engineering, 15(3), 201-215.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems — Requirements.

- American Petroleum Institute. (2021). API 6A: Specification for Wellhead and Christmas Tree Equipment.

- Davis, M. K. (2023). "Corrosion Resistance of Superalloys in Petrochemical Environments." Chemical Engineering Journal, 47(1), 89-102.

- NASA Technical Reports Server (NTRS). (Various years). Reports on honeycomb seal technology for propulsion systems.

Products categories

-

Stainless Steel Honeycomb Air Straightener IntakeNewsSep.01,2025

-

Advanced Honeycomb Gas Seal: Maximize Efficiency & ReliabilityNewsAug.31,2025

-

1.6mm Honeycomb Ring Seal: High-Performance, Reliable SealingNewsAug.30,2025

-

Steel Honeycomb CoreNewsAug.29,2025

-

Stainless Steel Honeycomb SheetNewsAug.29,2025

-

Honeycomb SealNewsAug.29,2025

-

2.5mm Honeycomb Seal: High-Performance, Durable Sealing SolutionsNewsAug.29,2025