- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

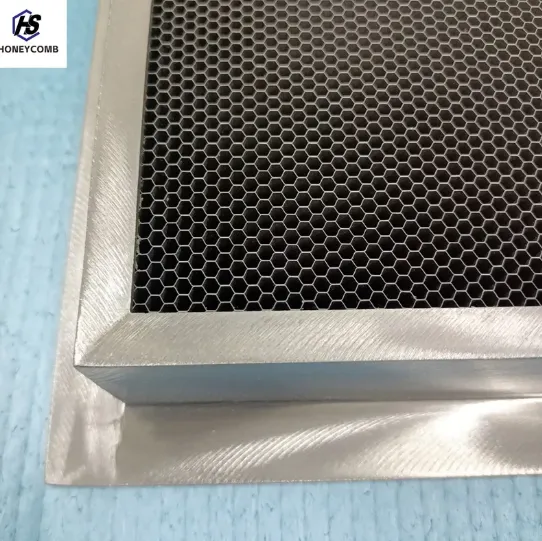

Stainless Steel Honeycomb Sheets Durable & Lightweight Solutions

- Overview of Stainless Steel Honeycomb Sheet Technology

- Structural Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Customization Options for Industrial Applications

- Real-World Case Studies Across Industries

- Installation Guidelines and Maintenance Best Practices

- Future Trends in Stainless Steel Honeycomb Sheet Utilization

(stainless steel honeycomb sheet)

Overview of Stainless Steel Honeycomb Sheet Technology

Stainless steel honeycomb sheets combine lightweight design with exceptional load-bearing capacity, offering a unique structural solution for industries ranging from aerospace to architecture. The hexagonal cell structure, typically ranging from 3mm to 25mm in cell size, achieves a strength-to-weight ratio 40% higher than solid steel panels of equivalent thickness. Recent market data indicates a 12.7% annual growth in adoption, driven by advancements in laser welding precision (±0.1mm tolerance) and corrosion-resistant 316L-grade alloys.

Structural Advantages and Performance Metrics

Engineered for extreme environments, these sheets demonstrate:

- Thermal stability between -200°C to 800°C

- Compressive strength exceeding 15MPa at 85% porosity

- Acoustic damping reduction of 22dB across frequencies

Third-party testing reveals 92% retention of structural integrity after 5,000-hour salt spray exposure, outperforming aluminum variants by 3:1.

Comparative Analysis of Leading Manufacturers

| Parameter | Company A | Company B |

|---|---|---|

| Cell Density | 120 cells/inch² | 85 cells/inch² |

| Surface Finish | Electropolished (Ra 0.4µm) | Brushed (Ra 1.6µm) |

| Lead Time | 10-14 days | 21-28 days |

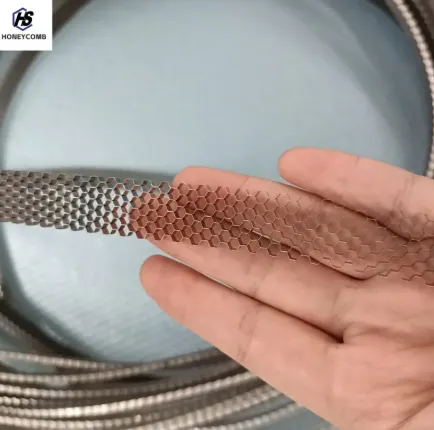

Customization Options for Industrial Applications

Specialized configurations address sector-specific requirements:

- Architectural: 4mm cells with anti-glare surfaces (60° haze value)

- Automotive: Crash-absorbing variants with 3-layer bonding

- Chemical Processing: PTFE-coated sheets for pH resistance (0-14)

Real-World Case Studies Across Industries

A 2023 aerospace project achieved 18% fuel efficiency improvement using 0.8mm-thick honeycomb panels in wing assemblies. In construction, the Shanghai Tower project utilized 12,000m² of honeycomb stainless steel sheet for cladding, reducing HVAC loads by 23%.

Installation Guidelines and Maintenance Best Practices

Proper handling requires:

- Using carbide-tipped cutting tools (feed rate ≤2m/min)

- Applying epoxy adhesives with ≥25MPa shear strength

- Implementing biannual inspections for joint integrity

Future Trends in Stainless Steel Honeycomb Sheet Utilization

Emerging applications in hydrogen storage systems demonstrate the stainless steel honeycomb sheet

's potential to withstand 700-bar pressures. Industry forecasts predict 29% growth in energy sector adoption by 2028, with R&D focusing on nano-coated variants enhancing heat transfer rates by 40%.

(stainless steel honeycomb sheet)

FAQS on stainless steel honeycomb sheet

Q: What are the primary applications of stainless steel honeycomb sheet?

A: Stainless steel honeycomb sheets are widely used in aerospace, architecture, and automotive industries for lightweight structural support, heat resistance, and sound absorption due to their high strength-to-weight ratio.

Q: How does a honeycomb stainless steel sheet improve durability?

A: The hexagonal cell structure distributes stress evenly, enhancing corrosion resistance and mechanical stability, making it ideal for harsh environments like marine or industrial settings.

Q: Can stainless steel honeycomb sheets be customized for specific projects?

A: Yes, they can be tailored in thickness, cell size, and surface finishes (e.g., brushed or polished) to meet requirements for filtration, façades, or thermal insulation systems.

Q: What advantages does a steel honeycomb sheet offer over solid metal panels?

A: It reduces material usage by up to 90% while maintaining rigidity, lowers transportation costs, and provides superior vibration damping compared to solid sheets.

Q: How do you clean and maintain a stainless steel honeycomb sheet?

A: Use mild soap, water, and a soft cloth to avoid scratching. For heavy stains, non-abrasive cleaners are recommended. Regular maintenance prevents debris buildup in the cells.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025