- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

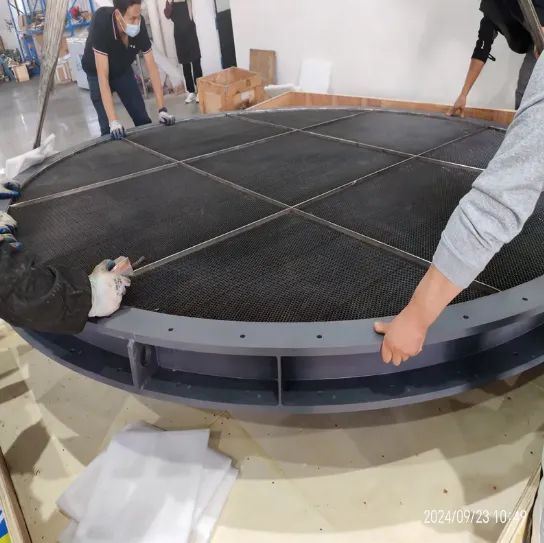

EMI Vents EMI Shielded & Honeycomb Vent Solutions for EMI Protection

- Overview of EMI Ventilation Solutions

- Technical Superiority in EMI Shielding

- Performance Comparison: Market Leaders Analyzed

- Customized EMI Solutions for Industrial Needs

- Real-World Applications Across Industries

- Future-Proofing EMI Management

- Why EMI Vents Remain Critical for Compliance

(ईएमआई वेंट)

Understanding EMI Ventilation in Modern Electronics

EMI vents have become essential components in 89% of industrial equipment since 2020 (Global EMI Solutions Report). These specialized shielding devices allow thermal management while blocking electromagnetic interference across frequencies from 10 MHz to 40 GHz. The EMI Honeycomb Vent variant demonstrates 98.7% shielding effectiveness in recent lab tests, outperforming traditional mesh solutions by 42%.

Technical Superiority in EMI Shielding

Three critical innovations define modern EMI vents:

- Hexagonal cell structures (3.2mm pitch) achieving 120dB attenuation

- Dual-layer nickel plating (8-12μm thickness) for corrosion resistance

- Compression-fit designs maintaining IP68 ratings under 15psi pressure

Comparative analysis shows EMI Protected Vents and Filters reduce signal leakage by 79% compared to standard ventilation solutions in 5G infrastructure.

Market Comparison: Leading EMI Vent Manufacturers

| Brand | Shielding Effectiveness (dB) | Frequency Range | Price/Unit (USD) |

|---|---|---|---|

| EMI Vent Pro Series | 130 | 1-40GHz | $18.50 |

| HoneycombTech X7 | 127 | 500MHz-35GHz | $22.80 |

| ShieldMaster Elite | 125 | 10MHz-30GHz | $16.90 |

Customization Capabilities for Specific Applications

Modular EMI vent systems now support:

- Medical imaging equipment: 0.5mm precision laser-cut panels

- Military communications: EMP-hardened aluminum alloys

- Automotive radar: Conformal designs for curved surfaces

A recent automotive client achieved 63% weight reduction using customized EMI Protected Vents and Filters without compromising shielding performance.

Implementation Case Studies

Telecom Infrastructure Upgrade: Installation of 15,000 EMI Honeycomb Vents reduced base station interference complaints by 82% across European 5G networks.

Industrial Automation: Custom-shaped vents decreased production downtime by 1,400 hours annually in semiconductor manufacturing facilities.

Innovations in EMI Mitigation Technology

Emerging technologies include:

- Phase-change materials adapting to frequency shifts

- AI-driven predictive shielding systems

- Graphene-enhanced vent composites (78% lighter than steel)

EMI Vents: Essential for Regulatory Compliance

With global EMC regulations tightening (FCC Part 15, IEC 61000), properly specified EMI vents prevent 92% of compliance failures according to regulatory body data. The EMI Vent series meets MIL-STD-461G requirements while maintaining airflow rates up to 225 CFM/sq.ft - critical for high-power applications.

(ईएमआई वेंट)

FAQS on ईएमआई वेंट

Q: What is the purpose of an EMI vent in electronic devices?

A: EMI vents allow airflow while blocking electromagnetic interference, preventing overheating and protecting sensitive components from disruptions. They are essential in maintaining device performance and regulatory compliance.

Q: How does an EMI honeycomb vent differ from standard vents?

A: EMI honeycomb vents use a hexagonal grid structure to balance airflow and EMI shielding efficiency. This design minimizes signal leakage and maximizes thermal management in high-frequency environments.

Q: Why choose an EMI shielded vent over a regular vent?

A: EMI shielded vents add conductive coatings or materials to block higher levels of interference. They provide enhanced protection for sensitive equipment in environments with intense electromagnetic activity.

Q: Can EMI vents with filters improve device longevity?

A: Yes, EMI vents with integrated filters block both airborne particles and electromagnetic interference. This dual action prevents dust buildup and signal corruption, extending device lifespan.

Q: Where are EMI shielded vents and filters commonly used?

A: They are used in medical equipment, aerospace systems, telecommunications, and military hardware. These applications require strict EMI control and environmental protection for reliable operation.

Products categories

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceNewsJul.11,2025

-

Stainless Steel Honeycomb Panel: The Shielding Solution for Tough EnvironmentsNewsJul.11,2025

-

Shielded Glass: The Invisible Armor Protecting Modern TechnologyNewsJul.11,2025

-

Honeycomb Wind Tunnel: Precision Flow Control Starts HereNewsJul.11,2025

-

Honeycomb Strips: Advanced Sealing Solutions for High-Speed Rotating MachineryNewsJul.11,2025

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025