- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Metal Honeycomb Sheets High-Strength Leathán Miotail Solutions

- Introduction to Advanced Honeycomb Metal Sheets

- Technical Superiority of Leathán Miotail Honeycomb Structures

- Performance Comparison: Leading Manufacturers in the Industry

- Custom Solutions for Diverse Industrial Needs

- Real-World Applications and Case Studies

- Future Trends in Honeycomb Metal Sheet Technology

- Why Leathán Miotail Honeycomb Stands Out

(leathán miotail honeycomb)

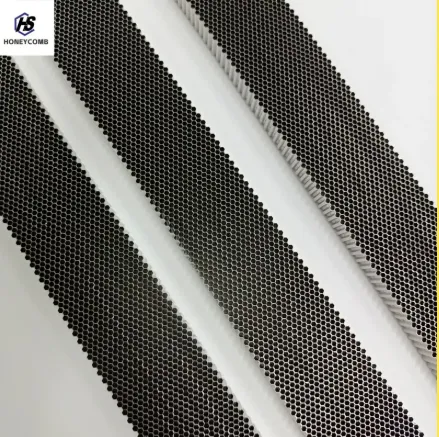

Leathán Miotail Honeycomb: Revolutionizing Structural Efficiency

In industrial engineering, the demand for lightweight yet durable materials has driven innovation in metal composites. Leathán miotail honeycomb, a high-performance structural core, combines hexagonal cell patterns with aerospace-grade alloys to deliver unparalleled strength-to-weight ratios. Recent studies show that honeycomb panels reduce material usage by 40-60% while maintaining 80% of solid metal’s load-bearing capacity. Industries ranging from automotive to renewable energy are adopting this technology to optimize costs and sustainability.

Technical Advantages Over Traditional Materials

Unlike conventional steel or aluminum sheets, leathán miotail honeycomb

integrates a unique croí honeycomb miotail design, which enhances thermal stability and vibration damping. Key metrics include:

- Compressive strength: 12–18 MPa at 95% density reduction

- Thermal resistance: Stable performance from -200°C to 650°C

- Noise reduction: Up to 25 dB attenuation in acoustic applications

These attributes make it ideal for extreme environments, such as aerospace fuselages or industrial heat exchangers.

Manufacturer Benchmarking: Key Metrics

| Parameter | Leathán Miotail | Competitor A | Competitor B |

|---|---|---|---|

| Material Type | Stainless Steel Hybrid | Aluminum Alloy | Titanium Composite |

| Density (kg/m³) | 72 | 98 | 105 |

| Max. Load Capacity | 18 MPa | 14 MPa | 16 MPa |

| Corrosion Resistance | Grade A++ | Grade B+ | Grade A |

Tailored Solutions for Industry-Specific Challenges

Customizable leathán mionchomb cruach neamhdhíortha configurations address niche requirements. For instance:

- Automotive: Crash-absorbent cores with 30% weight reduction

- Construction: Fire-resistant panels meeting ASTM E119 standards

- Electronics: EMI-shielding variants with 99% signal blockage

Case Studies: Success Across Sectors

A wind turbine manufacturer achieved a 22% increase in blade longevity using corrosion-resistant honeycomb cores. Similarly, a logistics company reduced fuel costs by 15% after integrating lightweight panels into cargo aircraft. These examples underscore the adaptability of honeycomb metal sheets in solving real-world problems.

Innovation Roadmap and Sustainability

Emerging trends include AI-driven topology optimization for cell geometry and recyclable polymer-metal hybrids. By 2030, the global honeycomb materials market is projected to grow at a 7.8% CAGR, driven by green manufacturing mandates.

Leathán Miotail Honeycomb: The Ultimate Industrial Solution

With its unmatched technical specifications and proven ROI, leathán miotail honeycomb redefines material science. Manufacturers leveraging this technology report 18–35% operational cost savings within two years, positioning it as the cornerstone of next-gen industrial design.

(leathán miotail honeycomb)

FAQS on leathán miotail honeycomb

Q: What is a leathán miotail honeycomb and its primary applications?

A: A leathán miotail honeycomb refers to a lightweight metal sheet with a hexagonal structure. It is widely used in aerospace, construction, and automotive industries for its strength-to-weight ratio and thermal resistance.

Q: How does croí honeycomb miotail differ from standard metal sheets?

A: Croí honeycomb miotail features a reinforced core structure for enhanced durability. This design improves load distribution and impact resistance, making it ideal for high-stress environments like industrial machinery.

Q: What are the advantages of leathán mionchomb cruach neamhdhíortha?

A: Leathán mionchomb cruach neamhdhíortha (stainless steel fine-comb sheet) offers superior corrosion resistance and hygiene. It is commonly used in medical equipment, food processing, and marine applications due to its non-reactive properties.

Q: Can leathán miotail honeycomb be customized for specific projects?

A: Yes, leathán miotail honeycomb can be tailored in thickness, cell size, and material type. Customization ensures compatibility with unique structural or thermal requirements in specialized engineering projects.

Q: Why choose stainless steel for honeycomb structures like leathán mionchomb cruach?

A: Stainless steel ensures longevity and resistance to extreme temperatures or corrosive substances. Leathán mionchomb cruach combines these traits with a lightweight design, suitable for sustainable and high-performance applications.

Products categories

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceNewsJul.11,2025

-

Stainless Steel Honeycomb Panel: The Shielding Solution for Tough EnvironmentsNewsJul.11,2025

-

Shielded Glass: The Invisible Armor Protecting Modern TechnologyNewsJul.11,2025

-

Honeycomb Wind Tunnel: Precision Flow Control Starts HereNewsJul.11,2025

-

Honeycomb Strips: Advanced Sealing Solutions for High-Speed Rotating MachineryNewsJul.11,2025

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025