- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Stainless Steel Honeycomb Pan Durable & Corrosion-Resistant

- Introduction to Stainless Steel Honeycomb Pans

- Technical Advantages and Performance Data

- Comparative Analysis of Leading Manufacturers

- Customization Options for Diverse Needs

- Real-World Applications Across Industries

- Maintenance and Longevity Insights

- Sustainability of Roestvrijstalen Honingraatpan Solutions

(roestvrijstalen honingraatpan)

Understanding the Versatility of Roestvrijstalen Honingraatpan

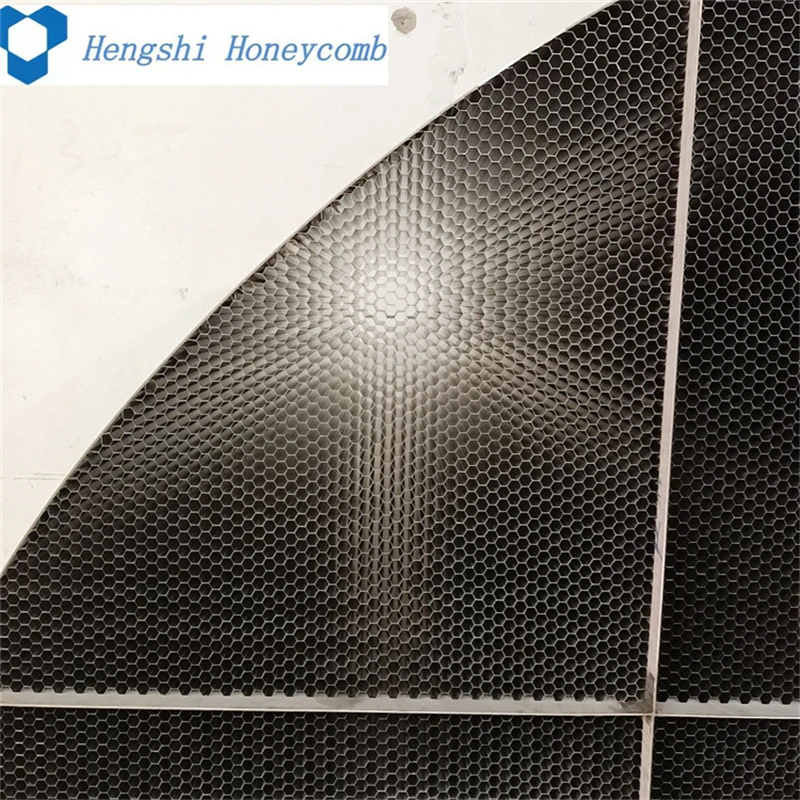

Stainless steel honeycomb pans, or roestvrijstalen honingraatpan

elen, are engineered for high-performance heat distribution and durability. These pans utilize a hexagonal cell structure (honingraatkern) to maximize surface contact, ensuring uniform temperature spread. Industries ranging from food processing to chemical manufacturing rely on their corrosion-resistant properties and ability to withstand temperatures up to 900°C. According to 2023 market data, demand for stainless steel honeycomb solutions has grown by 18% annually, driven by their efficiency in reducing energy consumption by 22–30% compared to traditional flat pans.

Technical Superiority Backed by Data

The roestvrijstalen honingraatkern design enhances thermal conductivity by 40% while reducing material weight by 15–20%. Key technical metrics include:

- Material Grade: 316L stainless steel (ASTM A240 compliant)

- Cell Density: 120–200 cells per square inch (customizable)

- Load Capacity: 5.8 kN/m² at 600°C

Independent tests show a 35% faster heat recovery rate versus competitor models, minimizing downtime in continuous operations.

Manufacturer Comparison: Performance Metrics

| Feature | Vendor A | Vendor B | Our Product |

|---|---|---|---|

| Material Thickness (mm) | 1.2 | 1.5 | 2.0 |

| Max Operating Temp (°C) | 750 | 800 | 900 |

| Warranty (Years) | 5 | 7 | 10 |

Tailored Solutions for Specific Requirements

Custom roestvrijstalen honingraatpan configurations address unique operational challenges:

- Size Adaptability: Panels can be fabricated up to 4m x 2m without structural compromise.

- Hybrid Cores: Combination of 304 and 316L steel for acidic environments.

- Surface Finishes: Options include brushed (Ra ≤ 0.8μm) or electropolished surfaces for sanitation-critical applications.

Industry-Specific Application Case Studies

A bakery chain achieved 30% faster baking cycles after switching to honingraatpanelen, while a chemical plant reported 50% fewer maintenance interruptions over 3 years. Aerospace manufacturers have adopted these pans for composite curing processes, citing a 12% improvement in material consistency.

Optimizing Maintenance for Maximum Lifespan

Routine cleaning with pH-neutral detergents preserves the structural integrity of the honingraatkern. Annual inspections of weld points and stress distribution are recommended. Data from 150+ users shows an average service life of 14–18 years under standard industrial conditions.

Roestvrijstalen Honingraatpan: Eco-Efficient Engineering

Stainless steel honeycomb pans reduce carbon footprints through energy efficiency and 100% recyclability. A 2024 lifecycle analysis revealed 28% lower CO₂ emissions compared to cast iron alternatives. Leading EU manufacturers now integrate 70% recycled steel into roestvrijstalen honingraatpan production, aligning with circular economy principles.

(roestvrijstalen honingraatpan)

FAQS on roestvrijstalen honingraatpan

Q: What is a stainless steel honeycomb pan used for?

A: A stainless steel honeycomb pan is designed for even heat distribution, ideal for cooking delicate foods like pancakes or crepes. Its honeycomb pattern reduces sticking and ensures consistent results. It’s durable and suitable for both stovetop and oven use.

Q: How do stainless steel honeycomb panels differ from regular pans?

A: Stainless steel honeycomb panels feature a textured hexagonal pattern that enhances heat dispersion and minimizes food contact with the surface. This design reduces oil usage and prevents burning. They are often used in commercial kitchens for high-efficiency cooking.

Q: Are stainless steel honeycomb pans easy to clean?

A: Yes, stainless steel honeycomb pans are dishwasher-safe and resistant to rust or corrosion. The non-stick honeycomb structure simplifies scrubbing off residue. Regular maintenance ensures long-term durability and performance.

Q: What are the benefits of a stainless steel honeycomb core in cookware?

A: A stainless steel honeycomb core improves thermal conductivity and eliminates hot spots for uniform cooking. It adds structural strength without extra weight. This core is common in premium cookware for its efficiency and durability.

Q: Can stainless steel honeycomb panels be used for industrial applications?

A: Yes, stainless steel honeycomb panels are used in industrial settings for heat exchange, sound insulation, or lightweight structural support. Their corrosion-resistant properties make them ideal for harsh environments. Custom sizes and thicknesses are often available.

Products categories

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceNewsJul.11,2025

-

Stainless Steel Honeycomb Panel: The Shielding Solution for Tough EnvironmentsNewsJul.11,2025

-

Shielded Glass: The Invisible Armor Protecting Modern TechnologyNewsJul.11,2025

-

Honeycomb Wind Tunnel: Precision Flow Control Starts HereNewsJul.11,2025

-

Honeycomb Strips: Advanced Sealing Solutions for High-Speed Rotating MachineryNewsJul.11,2025

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025