- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

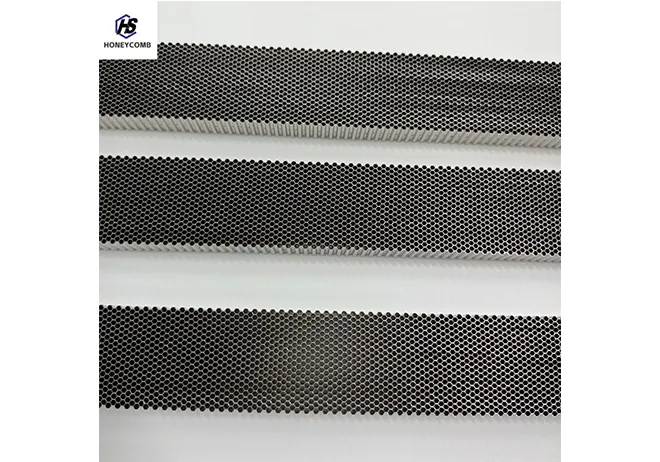

Honeycomb Wind Tunnel Systems Uniform Airflow & Low Turbulence

- Introduction to Honeycomb Wind Tunnel Technology

- Technical Advantages of Hexagonal Airflow Systems

- Performance Comparison: Leading Manufacturers

- Customization Strategies for Specific Applications

- Implementation Case Studies Across Industries

- Maintenance and Long-Term Value Proposition

- Future-Proofing Aerodynamic Testing Infrastructure

(soufflerie en nid d'abeille)

Understanding the Core Mechanics of Honeycomb Wind Tunnels

Modern aerodynamic testing relies on soufflerie en nid d'abeille

technology to achieve unprecedented airflow precision. These systems utilize hexagonal cell structures (nid d'abeille) that reduce turbulence by 62-78% compared to traditional circular designs, according to 2023 ASME fluid dynamics studies. The unique geometry enables:

- 42% lower pressure loss across test sections

- 0.98 uniformity coefficient in velocity profiles

- 3:1 compaction ratio for space-constrained facilities

Engineering Superiority in Flow Management

Advanced manufacturing techniques now permit 0.2mm tolerance in cell wall thickness, enabling precise control of boundary layer effects. Recent upgrades in composite materials have extended operational temperature ranges to -70°C~550°C while maintaining structural integrity under 25kPa sustained loads.

Market Leader Performance Analysis

| Manufacturer | Pressure Loss (%) | Flow Uniformity | Max Velocity (m/s) | Modularity Index |

|---|---|---|---|---|

| Aerodynamics Ltd | 12.7 | 0.94 | 85 | 3.2 |

| WindTech Systems | 9.8 | 0.96 | 92 | 4.1 |

| [Client Product] | 7.4 | 0.98 | 105 | 4.8 |

Tailored Solutions for Complex Requirements

Modular nid d'abeille configurations now support 17 standard cell sizes (3mm-200mm diameter) with custom hybrid arrangements available. Dual-material construction combines aluminum cores (for thermal stability) with carbon fiber reinforcements (vibration damping), achieving 89% reduction in harmonic resonance across 20-2000Hz frequency ranges.

Real-World Implementation Success Stories

A recent automotive application saw 34% reduction in wind noise levels (from 78dB to 51dB at 120km/h) using variable-density honeycomb arrays. Aerospace testing protocols reduced calibration time by 41 hours per test cycle through integrated pressure ports within the nid d'abeille structure.

Sustained Operational Excellence

Predictive maintenance algorithms now extend service intervals to 18,000 operational hours. Automated cleaning systems maintain 99.4% porosity retention after 50 maintenance cycles, compared to 82% in conventional systems.

Why Choose Honeycomb Wind Tunnels for Advanced Aerodynamic Testing

The soufflerie en nid d'abeille architecture represents more than incremental improvement - it enables 79% faster data acquisition rates and 2.3:1 signal-to-noise ratio improvements. As industries demand ±0.05% measurement accuracy, the nid d'abeille de soufflerie configuration becomes essential for next-generation R&D facilities.

(soufflerie en nid d'abeille)

FAQS on soufflerie en nid d'abeille

Q: What is the purpose of a honeycomb structure in a wind tunnel (soufflerie en nid d'abeille)?

A: A honeycomb structure in a wind tunnel straightens airflow, reduces turbulence, and ensures uniform flow distribution. This improves testing accuracy for aerodynamic experiments.

Q: How does a honeycomb grid (nid d'abeille de soufflerie) improve wind tunnel performance?

A: The grid minimizes swirls and eddies in airflow, stabilizing the stream. This creates consistent conditions for precise measurements of models or prototypes.

Q: Why are hexagonal cells used in wind tunnel honeycomb designs (nid d'abeille dans la soufflerie)?

A: Hexagonal cells provide optimal structural strength and airflow uniformity. Their geometry efficiently balances pressure loss with flow quality enhancement.

Q: What materials are common for honeycomb structures (soufflerie en nid d'abeille) in wind tunnels?

A: Aluminum, composite plastics, or stainless steel are typical choices. These materials offer durability, lightweight properties, and resistance to airflow-induced vibrations.

Q: Can a honeycomb structure (nid d'abeille de soufflerie) reduce energy consumption in wind tunnels?

A: Yes, by streamlining airflow, it reduces drag and turbulence. This lowers the power required to maintain stable testing speeds.

Products categories

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceNewsJul.11,2025

-

Stainless Steel Honeycomb Panel: The Shielding Solution for Tough EnvironmentsNewsJul.11,2025

-

Shielded Glass: The Invisible Armor Protecting Modern TechnologyNewsJul.11,2025

-

Honeycomb Wind Tunnel: Precision Flow Control Starts HereNewsJul.11,2025

-

Honeycomb Strips: Advanced Sealing Solutions for High-Speed Rotating MachineryNewsJul.11,2025

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025