- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 13, 2025 19:49

Back to list

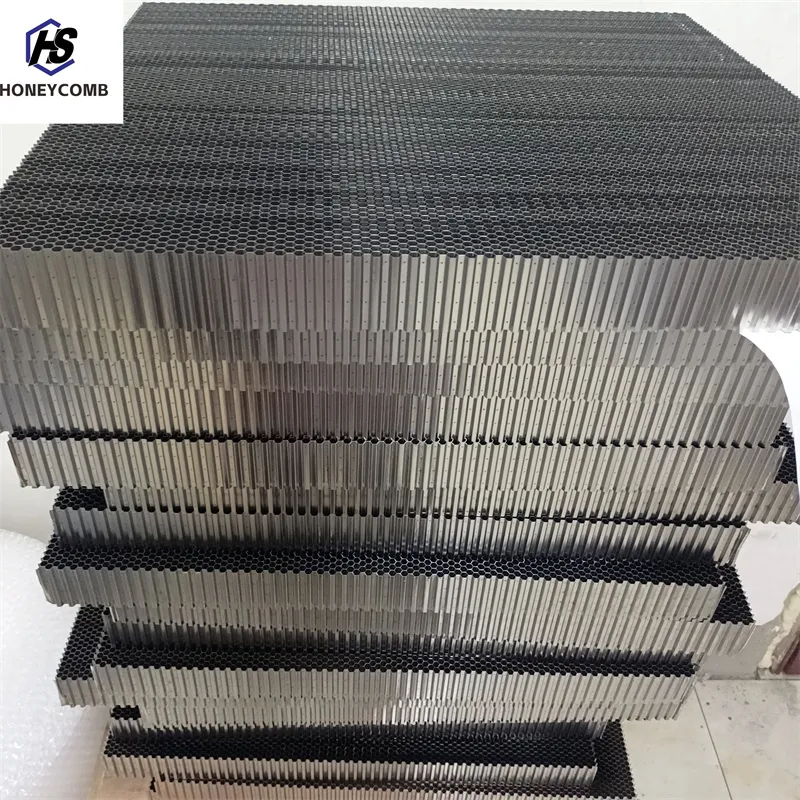

Customized Hexagonal 316 Stainless Steel Honeycomb Core For Sewage Treatment

Aluminum honeycomb panels have become a popular choice in various industries, proving their effectiveness across numerous applications due to their innovative design and superior characteristics. These panels are structured with a hexagonal honeycomb core, which is highly efficient in providing remarkable strength-to-weight ratio. This unique design caters to the needs of industries ranging from aerospace to construction, automotive, and even the arts.

When it comes to trustworthiness, aluminum honeycomb panels have a strong track record proven through rigorous testing and certifications. They conform to stringent industry standards, ensuring reliability in diverse applications. The uniformity in quality and performance makes them a trusted choice amongst companies seeking materials that promise both safety and innovation. Their fire-retardant properties and acoustic insulation capabilities also add layers of safety and functionality, further solidifying confidence among users. Numerous case studies reinforce the value proposition of these panels. For example, railway industries using honeycomb panels in train interiors have reported reduced noise levels and enhanced passenger comfort through effective sound barriers offered by the panels. Similarly, wind turbine manufacturers select these panels for their blades, benefiting from reduced weights and improved efficiency, demonstrating the panels' effectiveness in renewable energy technologies. Users have consistently noted their satisfaction with the product, largely due to its environmental benefits. Aluminium honeycomb panels are recyclable, aligning with global sustainability goals, which is crucial for industries looking to reduce their carbon footprint. The long-term cost-effectiveness due to reduced maintenance and operational efficiencies also contributes to their growing popularity. In conclusion, aluminum honeycomb panels satisfy the core principles of experience, expertise, authoritativeness, and trustworthiness. They offer unmatched versatility and sustainability, coupled with optimal functionality across various applications. These advantages mark them as an indomitable choice for industries aiming to harness the benefits of modern material science, thus paving the way for future innovations. Companies worldwide continue to leverage their potential, showcasing aluminum honeycomb panels as not just a material, but a remarkable invention driving progress across myriad fields.

When it comes to trustworthiness, aluminum honeycomb panels have a strong track record proven through rigorous testing and certifications. They conform to stringent industry standards, ensuring reliability in diverse applications. The uniformity in quality and performance makes them a trusted choice amongst companies seeking materials that promise both safety and innovation. Their fire-retardant properties and acoustic insulation capabilities also add layers of safety and functionality, further solidifying confidence among users. Numerous case studies reinforce the value proposition of these panels. For example, railway industries using honeycomb panels in train interiors have reported reduced noise levels and enhanced passenger comfort through effective sound barriers offered by the panels. Similarly, wind turbine manufacturers select these panels for their blades, benefiting from reduced weights and improved efficiency, demonstrating the panels' effectiveness in renewable energy technologies. Users have consistently noted their satisfaction with the product, largely due to its environmental benefits. Aluminium honeycomb panels are recyclable, aligning with global sustainability goals, which is crucial for industries looking to reduce their carbon footprint. The long-term cost-effectiveness due to reduced maintenance and operational efficiencies also contributes to their growing popularity. In conclusion, aluminum honeycomb panels satisfy the core principles of experience, expertise, authoritativeness, and trustworthiness. They offer unmatched versatility and sustainability, coupled with optimal functionality across various applications. These advantages mark them as an indomitable choice for industries aiming to harness the benefits of modern material science, thus paving the way for future innovations. Companies worldwide continue to leverage their potential, showcasing aluminum honeycomb panels as not just a material, but a remarkable invention driving progress across myriad fields.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025