- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 00:25

Back to list

قرص عسل من الألومنيوم المبثوق

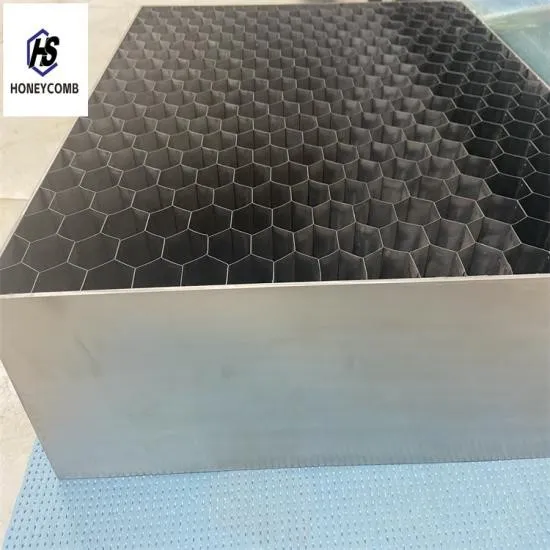

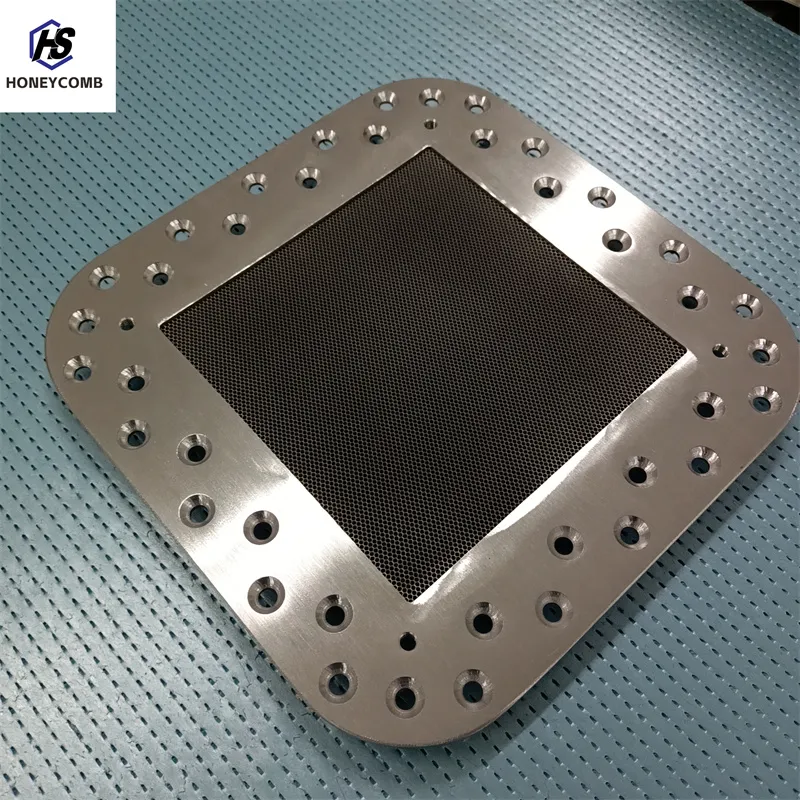

The extruded aluminum honeycomb panel has emerged as an indispensable component in various industries, renowned for its lightweight yet exceptionally strong and durable properties. They boast a honeycomb-like structure, providing an optimal strength-to-weight ratio, which makes them particularly advantageous for applications ranging from aerospace to architecture.

Industries concerned with environmental impact find a particularly good ally in extruded aluminum honeycomb panels. Aluminum is an infinitely recyclable material, and the production process for these panels is aligned with sustainable practices. This recyclability does not compromise its mechanical properties, ensuring that the panels can be reused without degrading quality—essential in a time when environmental concerns are more pressing than ever. Adopting extruded aluminum honeycomb technology can lead to cost savings across various sectors. Its fabrication process is efficient, leading to lower manufacturing costs. For the end-user, the reduced weight of end products results in operational savings, such as lower transportation costs due to weight reduction and increased fuel efficiency in vehicles and airplanes. However, the successful implementation of these panels relies heavily on understanding the nuances of different industry applications. Professionals working with these materials must possess a keen awareness of how each unique environment interacts with aluminum panels. This expertise ensures that the panels perform optimally and meet the specific needs of the project—whether that involves thermal management, sound insulation or load distribution. When sourcing extruded aluminum honeycomb panels, working with reputable suppliers who adhere to international quality standards is crucial. This ensures that the panels not only perform as expected but also last through the rigors of their environments, reinforcing the trustworthiness that industries demand from such materials. As with any specialized product, ongoing research and innovation continue to drive improvements in performance and manufacturing techniques of these panels. Staying updated with technological advancements and industry needs is key for businesses looking to leverage this versatile material in their future projects.

Industries concerned with environmental impact find a particularly good ally in extruded aluminum honeycomb panels. Aluminum is an infinitely recyclable material, and the production process for these panels is aligned with sustainable practices. This recyclability does not compromise its mechanical properties, ensuring that the panels can be reused without degrading quality—essential in a time when environmental concerns are more pressing than ever. Adopting extruded aluminum honeycomb technology can lead to cost savings across various sectors. Its fabrication process is efficient, leading to lower manufacturing costs. For the end-user, the reduced weight of end products results in operational savings, such as lower transportation costs due to weight reduction and increased fuel efficiency in vehicles and airplanes. However, the successful implementation of these panels relies heavily on understanding the nuances of different industry applications. Professionals working with these materials must possess a keen awareness of how each unique environment interacts with aluminum panels. This expertise ensures that the panels perform optimally and meet the specific needs of the project—whether that involves thermal management, sound insulation or load distribution. When sourcing extruded aluminum honeycomb panels, working with reputable suppliers who adhere to international quality standards is crucial. This ensures that the panels not only perform as expected but also last through the rigors of their environments, reinforcing the trustworthiness that industries demand from such materials. As with any specialized product, ongoing research and innovation continue to drive improvements in performance and manufacturing techniques of these panels. Staying updated with technological advancements and industry needs is key for businesses looking to leverage this versatile material in their future projects.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025