- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 09:27

Back to list

हनीकॉम्ब शीट मेटल

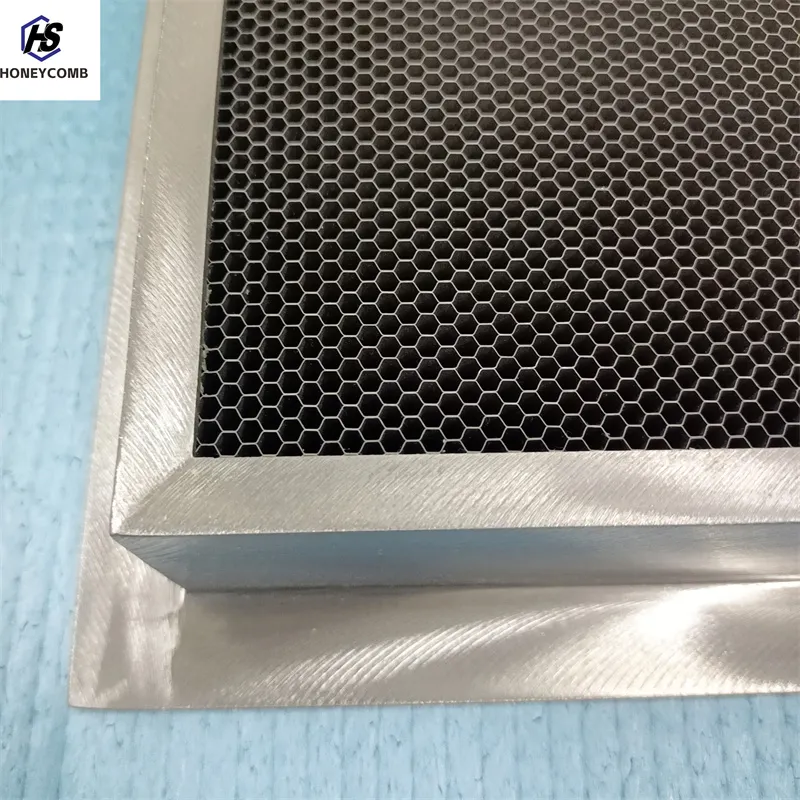

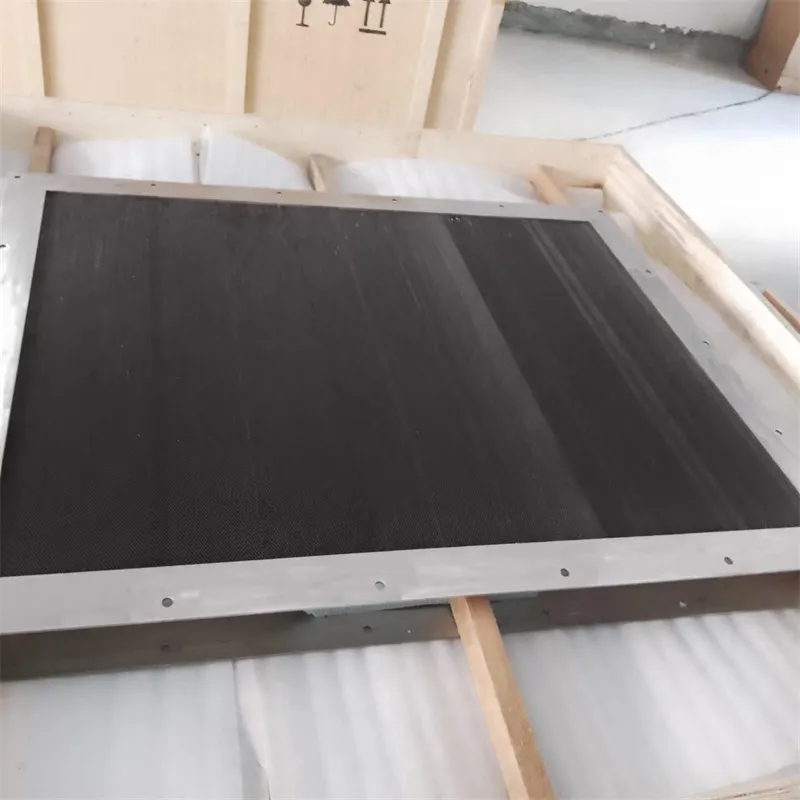

In the realm of modern engineering and construction, the honeycomb sheet metal has emerged as a revolutionary material, known for its unique combination of lightweight structure and high strength. Offering an exceptional ratio of weight to permanence, honeycomb sheet metal is rapidly becoming the preferred choice for industries seeking to optimize their designs for aerodynamics, efficiency, and sustainability.

Authority in the field of materials science reiterates that honeycomb sheet metal is not merely a trend, but rather a cornerstone of future innovation. Academic journals and industry publications present extensive research on its application and benefits, reinforcing its status within engineering communities worldwide. Organizations focusing on structural efficiency and material science consistently highlight its role in groundbreaking projects, thus establishing it as a critical component in the evolution of smart and sustainable construction materials. Trustworthiness is inherent in honeycomb sheet metal products due to the rigorous testing and quality control measures adopted during production. Manufacturers today employ stringent testing methodologies to ensure each sheet meets the high standards demanded by sectors like aerospace, where safety and reliability cannot be compromised. Unit tests for tensile strength, compression, and impact resistance, along with certifications from authoritative bodies, ensure that each product fulfills its promise of superior performance. These assurances build confidence among engineers, architects, and project managers in its use across diverse applications. With its blend of experience-driven functionality, advanced technological underpinnings, authoritative endorsements, and proven reliability, honeycomb sheet metal is poised to drive the next wave of innovation across multiple sectors. Its versatility and adaptability align perfectly with the emerging industrial need for greener, smarter, and more efficient materials. As research continues and technology evolves, the potential applications for honeycomb sheet metal are bound to expand, solidifying its place as a pivotal material shaping the future landscape of engineering and design.

Authority in the field of materials science reiterates that honeycomb sheet metal is not merely a trend, but rather a cornerstone of future innovation. Academic journals and industry publications present extensive research on its application and benefits, reinforcing its status within engineering communities worldwide. Organizations focusing on structural efficiency and material science consistently highlight its role in groundbreaking projects, thus establishing it as a critical component in the evolution of smart and sustainable construction materials. Trustworthiness is inherent in honeycomb sheet metal products due to the rigorous testing and quality control measures adopted during production. Manufacturers today employ stringent testing methodologies to ensure each sheet meets the high standards demanded by sectors like aerospace, where safety and reliability cannot be compromised. Unit tests for tensile strength, compression, and impact resistance, along with certifications from authoritative bodies, ensure that each product fulfills its promise of superior performance. These assurances build confidence among engineers, architects, and project managers in its use across diverse applications. With its blend of experience-driven functionality, advanced technological underpinnings, authoritative endorsements, and proven reliability, honeycomb sheet metal is poised to drive the next wave of innovation across multiple sectors. Its versatility and adaptability align perfectly with the emerging industrial need for greener, smarter, and more efficient materials. As research continues and technology evolves, the potential applications for honeycomb sheet metal are bound to expand, solidifying its place as a pivotal material shaping the future landscape of engineering and design.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025